ANTIFIRE FIRE MONITOR COMPLEX (LPK)

TU 28.99.39-051-72410778-2019

Description

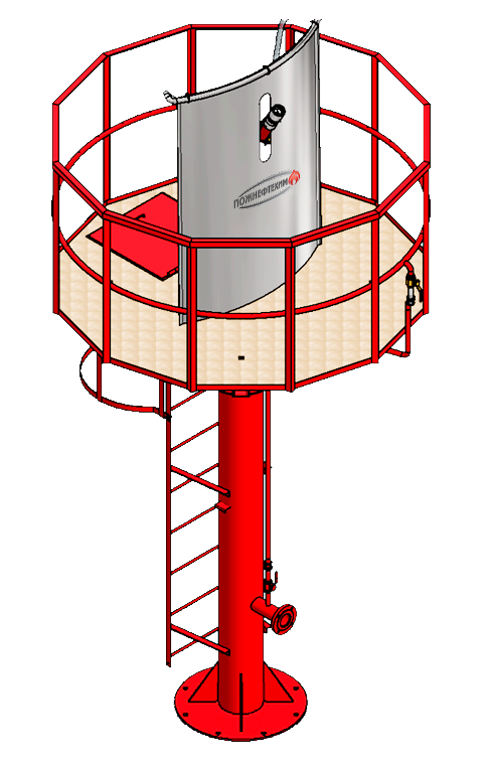

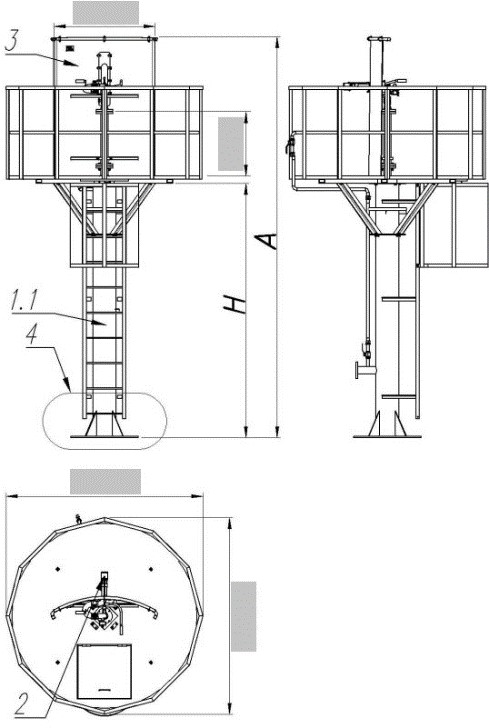

The Antifire fire monitor complex (LPK) consists of a fire monitor (LS) according to GOST R 51115-97, a universal fire tower (PVU) and a water heat-protective screen (VPE).

The firefighting monitor system can be supplied with auxiliary equipment. It is recommended that a Tauer PFU universal firefighting filter be installed upstream the LPK complete with a maintenance unit and a 1x1 mm mesh. Moreover, a Foamix DPN-S type pressure fire proportioner is required when using a firefighting monitor of LS-SU type.

Optionally, the system can be equipped with a remote control firefighting monitor (LSD).

Purpose and scope

The Antifire fire monitor complex (LPK) is designed for applying firefighting substances over long distances for extinguishing or water cooling of the protected object. The mission of the fire monitor complex is to provide a monitor operator with working environment in a fire or to shield the remote controlled firefighting monitor (LSD) from any heat flux.

The Antifire firefighting monitor system ensures the effective use of a water heat-protective screen with the fire extinguishing and water cooling systems. The VPE is mounted in accordance with SP 155.13130, SP 326.1311500.2017, and SP 231.1311500.2015.

The firefighting monitor system includes:

1.1 – one monitor universal fire tower (PVU)

2 – Antifire fire monitor (LS)

3 – water heat-protective screen (VPE)

4 – LPK base

Distinctive advantages

Stability when working in conditions of elevated temperatures and heat fluxes.

Turnkey complete solution for fire extinguishing with firefighting monitors.

Usability in mounting and implementation.

Technical characteristics and spares dimensions are unified by hydraulic characteristics and designs.

Materials of manufacture

In terms of resistance to climatic effects, the Antifire LPK can be manufactured for U, HL, UHL, T, OM conditions in accordance with GOST 15150-69.

The Antifire element (LPK) |

Climatic models / Material of construction |

|||

U |

HL, UHL |

T, OM |

||

Universal fire tower (PVU) |

steel 20, 09G2S |

09G2S |

||

Antifire firefighting monitor (LS) |

turnable |

12Х18Н10Т |

||

Nozzle (LS-S) |

AD1 |

|||

Nozzle (LS-SU) and |

12Х18Н10Т |

|||

water heat-protective screen (VPE) |

12Х18Н10Т |

|||

Key Specifications

Indicator name |

Indicator value |

||||||||||||

Antifire fire monitor complex (LPK) |

|||||||||||||

The height of the support platform to accommodate the operator(s), m |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 |

12 |

||

Number of firefighting monitors (LS), pcs. |

1 or 2 |

||||||||||||

Nominal pressure, MPa |

1,6 |

||||||||||||

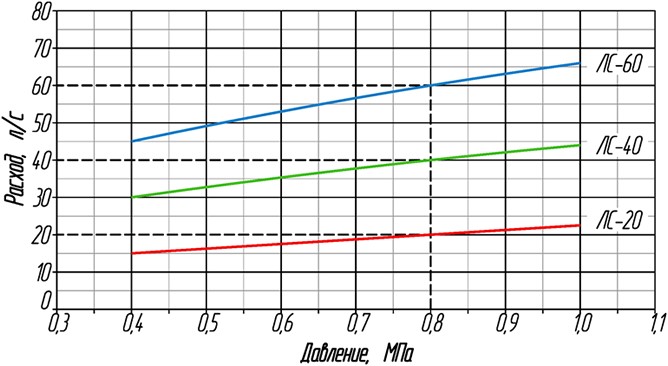

Monitor operating pressure range, MPa |

(0,4-1,0) |

||||||||||||

PVU rack spraying density, l/(s·m), min |

1 |

||||||||||||

PVU platform spraying density, l/(s·m), min (*) |

1 |

||||||||||||

Firefighting monitor type (LS) |

Antifire water applying nozzle LS-S type |

||||||||||||

LS rated flow, l/s |

20 l/s |

40 l/s |

60 l/s |

||||||||||

LS operating pressure range, MPa |

(0,4-1,0) |

||||||||||||

Jet spread range (by the most distant drops), m, min: |

|

|

|

||||||||||

Filling out the form means that you have read the privacy policy at the site www.pnx-spb.ru .

Стандарт Пожнефтехим "Базовые проблемы проектирования систем пенного пожаротушения. Пути решения". 2018 (pdf, 2.32 Mb)

Contact information for orders of Pozhneftehim package supplies

On the selection of foam concentrate

Tatyana Potapenko, head of foam concentrates department +7 (499) 703 01 32, ext.172

On the selection of equipment

Sergey Vypritsky, head of design department +7 (499) 703 01 32, ext.153

On Fire safety measures (MOPB) and Special technical conditions (STU) documents

Sergey Titenkov, head of technical norms department +7 (499) 703 01 32, ext.159