TANK FARM FIRE PROTECTION. EXTINGUISHING FIRE IN TANKS

The Pozhneftehim supports the designing of fire protection systems and manufactures equipment and foam concentrates for tank farms’ extinguishing systems.

Over 10-year experience in cooperation with leading oil and gas and petrochemical organizations allows creating economically feasible and efficient systems with due concideration of facility characteristics and legal requirements.

Choose your fire extinguishing system

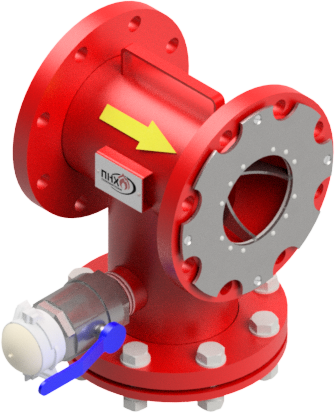

Tauer universal fire filter (PFU)

Tauer universal fire filter (PFU)

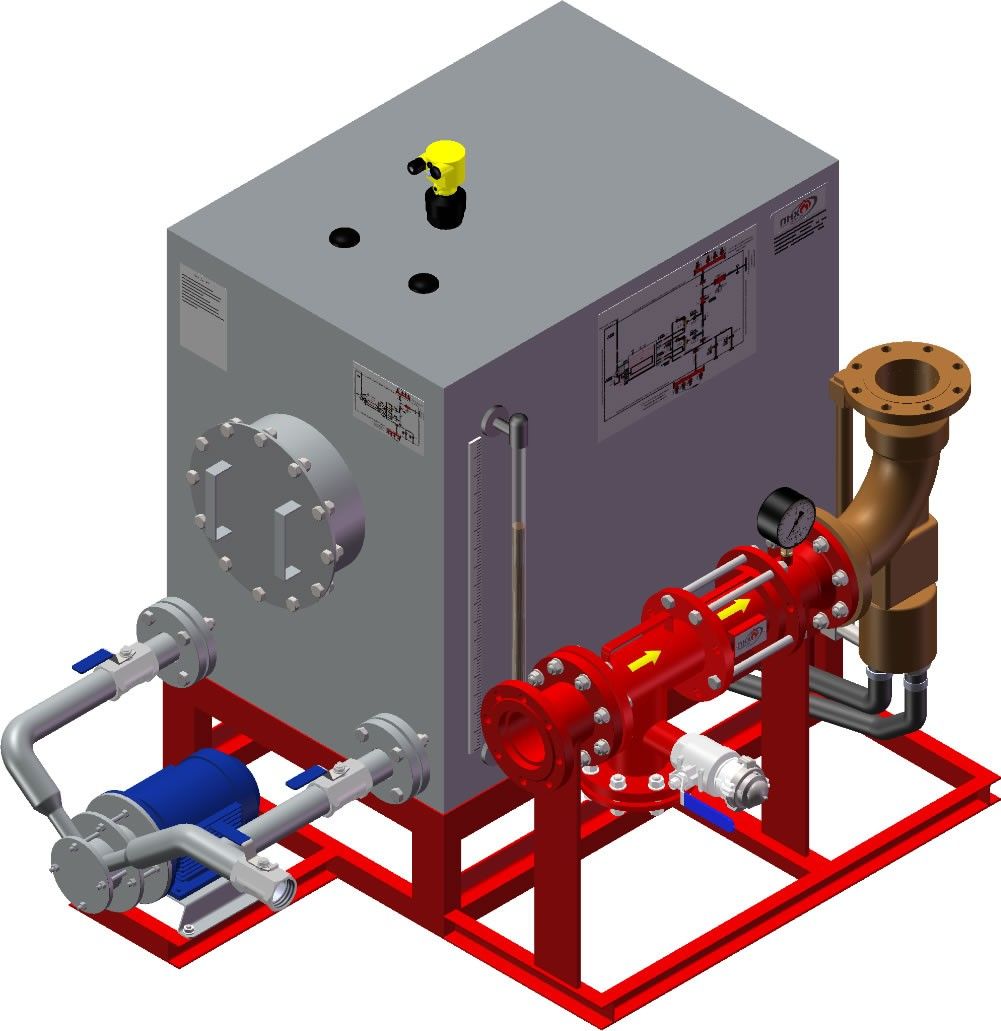

Vityaz block-container for fire suppression (BK-PT)

Vityaz block-container for fire suppression (BK-PT)

Foam concentrate storage and proportioning system (SKhDP)

Foam concentrate storage and proportioning system (SKhDP)

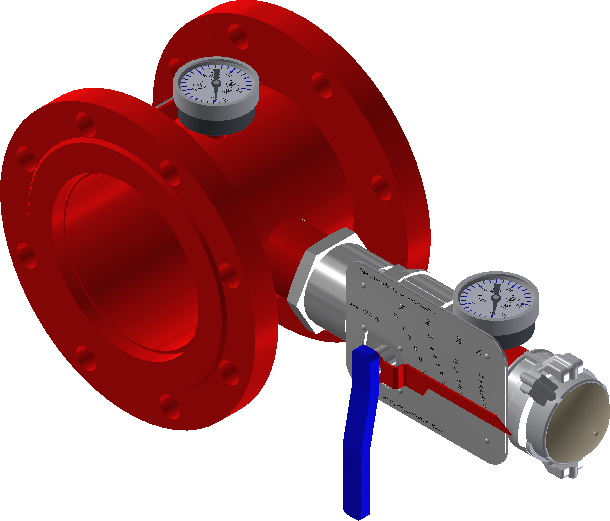

Foamix Fixed fire pressure proportioner (DPN)

Foamix Fixed fire pressure proportioner (DPN)

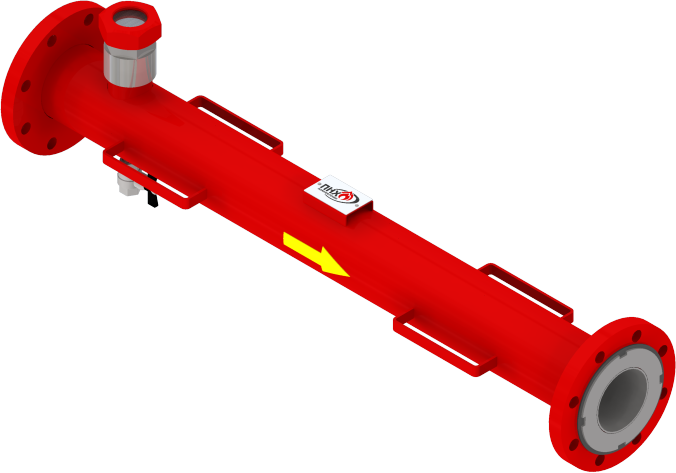

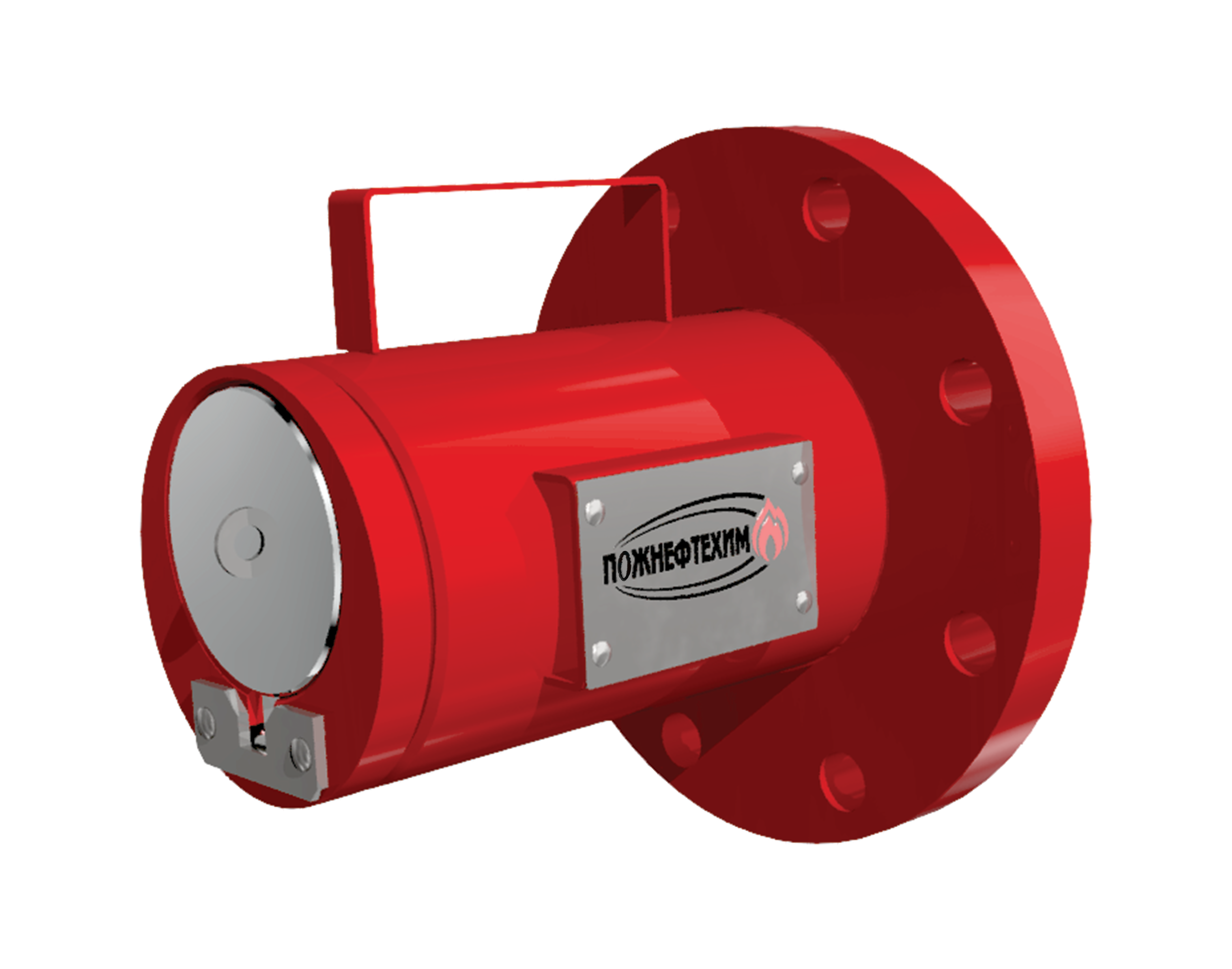

Shturm high back pressure foam generator (VPG)

Shturm high back pressure foam generator (VPG)

Warning!

The regulatory framework (SP 155.13130) allows the use of different fire extinguishing methods using stationary fire extinguishing systems, technical solutions and fire fighting equipment. Wrong choice of the main design decisions can lead to the implementation of an apriori unworkable fire extinguishing system.

The main fault in designing fire protection systems for tank farms is the use of a filled network of solution pipelines. Foam concentrates available on the Russian market do not have any guarantee for storage in solution! Such a system will not justify multi-million costs and may fail in the first months of operation.

Important! The use of alternative extinguishing methods, not confirmed by international practice, increases the probability of an emergency at the facility in case of accidental start. The use of alternative extinguishing methods requires the involvement of industrial safety experts.

Fire protection of tank farms

Tank farm fires are dangerous both for the industrial facility itself and for settlements located in the immediate vicinity. Inaccuracies in design, installation and maintenance of fire extinguishing systems may have social, financial, environmental, and infrastructural consequences.

The fire protection of the oil and oil products tank farm depends on the specifics of the facility: what tanks are installed on the site, what flammable and combustible liquids are stored therein and in what amounts. The main section of the project «Fire safety measures» (MOPB) should contain both regulatory and technical justification for decisions. Pozhneftehim has experience in developing MOPB for hazardous production facilities and carries out a range of works to ensure fire safety under the license of the Ministry of Emergencies of the Russian Federation.

The fire safety system includes not only fire extinguishing means, but also the organization’s internal regulations to prevent fire. Among them:

- Organization policy in the field of industrial safety, labor, environment protection

- Organization standards for emergency preparedness and corporate training on fire safety

- Requirements for contractors, instructions for organizing safe conduct at open fire, gas hazardous and other works

The internal organization security documents are mandatory for all employees and invited specialists.

Methods of fighting fire in a tank

According to SP 155.13130.2014 “Warehouses for oil and oil products”, the main means of extinguishing fires in oil and oil products tanks is medium- and low expansion foam applied to the surface of a combustible liquid.

The main provisions for foam fire extinguishing systems are prescribed in federal law 123-FZ "Technical regulation on fire safety requirements". Other official standards and codes of practice regulate the use of fire extinguishing systems, firefighting equipment, foam concentrate (extinguishing agent), foam generators, etc.

Read more on the topic:

The Pozhneftehim recommends using the following foam extinguishing methods for fire protection of tank farms:

- application of a film-forming low or medium expansion foam from the top downward onto the surface of the oil product using heat and explosion resistant chambers of low expansion foam in the tank upper zone;

- application of a low expansion foam through subsurface nozzles into the stratum of the oil product to reduce the burning area in the tanks;

- universal method with application of foam to the surface and/or into the stratum of flammable and combustible liquids.

The working solution of foam concentrate is applied to the surface of the fuel from the top downward through the wall of the tank using the Vega low expansion foam produced by the Pozhneftehim. For the method of subsurface application, a Shturm high back pressure foam generator, a burstable membrane and an Interlayer subsurface nozzle are recommended. Aquafom AFFF and AFFF/AR fluorosynthetic foam concentrates are recommended to use depending on the type of combustible/flammable liquid in the tank. Non-polar liquids shall be extinguished with AFFF foam concentrate, polar liquids – with AFFF/AR.

The principle of action of fire extinguishing systems (firefighting) and water cooling in tanks

Cooling of a burning tank and adjacent tanks of the RVS type (vertical steel tank) is the first priority of stationary installations and fire units. For this end, a water cooling unit with a pump station is created. In the event of a fire, it begins to work both on the ignited tank, and on the tanks adjacent to it. An installation of water cooling requires an underground circular water line with fire hydrants. Water also flows from it to the foam proportioners (BK-PT Vityaz) of the foam fire extinguishing systems.

Read more on the topic:

Depending on the required response time of the system (the time span for the foam fire extinguishing system to start functioning), a centralized or decentralized storage and proportioning system of the foam concentrate (SKhDP) can be used in the tank farm. The point of storage and preparation of the foam concentrate solution may be located at a greater or lesser distance from the tank.

The response time of the foam fire extinguishing system directly depends on the length of the solution line that connects the foam concentrate storage and propotioning system and a protected tank. The main reason for the system failure is the use for extinguishing a non-heat/non-explosion-proof generators of medium expansion foam and low-quality foam concentrate. If the foam concentrate is non-compliant with GOST, it loses its properties before the expiration date. When stored in a pipeline, the premix decomposes within one to two months. It is possible to check the fire extinguishing properties of the foam concentrate only during expensive fire tests in accredited laboratories equipped with a test site.

Read more on the topic:

The traditional top-down fire fighting technique developed in the 1960s consists in the use of a medium expansion foam, a GPS foam generator and a synthetic foam concentrate. Medium expansion foam can enter the tank by rigid application method which is one of its drawbacks. In addition, the foam premix solution of synthetic foam concentrate S-type does not protect the tank from burn back.

The risk of re-ignition of a combustible or flammable liquid (for some substances the flash point is less than 28 °C) is the main reason for choosing fluorosynthetic foam concentrate.

Read more on the topic:

The foam fire extinguishing systems (installations) with turbine inline and balanced pressure proportioners require the AFFF and AFFF/AR foam concentrates.

It is important that the selected foam concentrate meets the requirements of the fire equipment available at the facility, and the fire extinguishing efficiency is confirmed by testing at the test stand, taking into account the quality of water and fuel at the facility. When choosing the volume concentration, frost resistance and viscosity of a fluorosynthetic product, we recommend you to consult a specialist of the manufacturing company.

Contact information to order Pozhneftehim complex supplies

Questions concerning the choice of foam concentrates for fire extinguishing

Tatyana Potapenko, foam project manager +7 (499) 703 01 32, ext.172

Questions concerning the choice of firefighting equipment

Sergey Vypritsky, Project Manager +7 (499) 703 01 32, ext.153

Questions on documentation regarding Fire safety measures (MOPB) and Special technical conditions (STU)

Sergey Titenkov, Head of Regulatory and Technical Department +7 (499) 703 01 32, ext.159

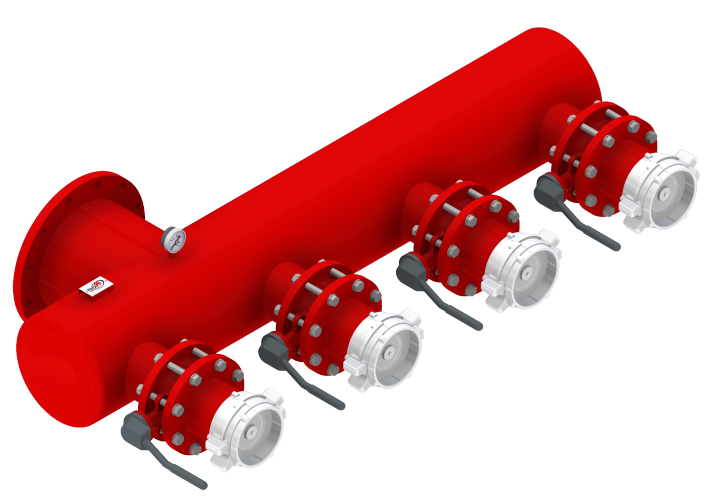

Fire hydrant manifolds (UPT)

Fire hydrant manifolds (UPT) Fire stabilizer (PUS)

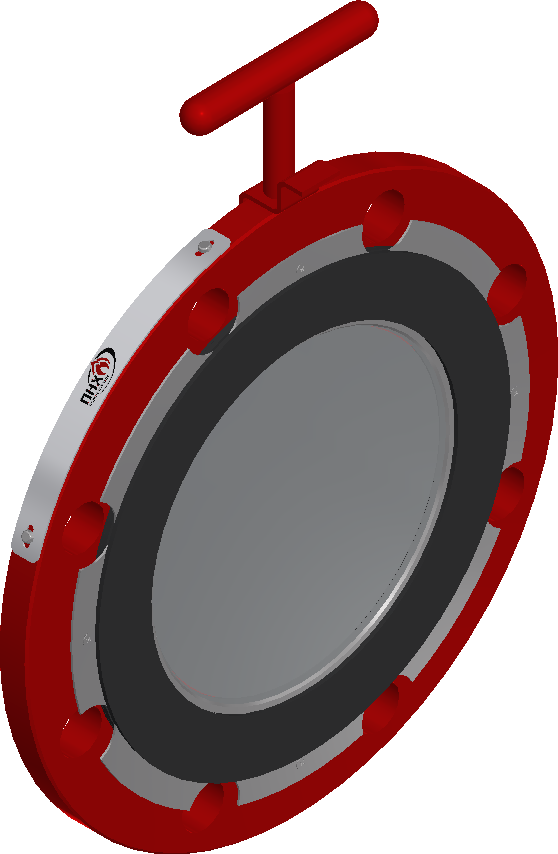

Fire stabilizer (PUS) Burstable membrane (МR)

Burstable membrane (МR)  Vega low expansion foam chamber (KNP)

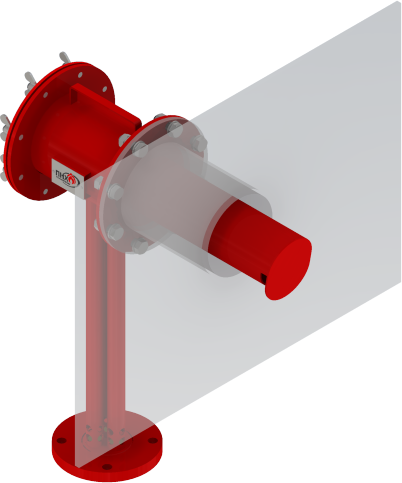

Vega low expansion foam chamber (KNP) Interlayer fire nozzle (PN)

Interlayer fire nozzle (PN)