15.11.2018 10:26:00

Pozhneftehim started working on the project of the Italian engineering company Tecnimont in 2016 as counterparty for the construction of the Moscow oil refinery. This is one of the projects that Pozhneftehim completed according to European management technologies. Our company was selected as the organization responsible for fire extinguishing systems. We value complex approach and want to tell more about our principles of collaboration with engineering companies.

What is the ideal counterparty for an engineering company?

The engineering company is responsible for the full cycle of design, construction and commissioning of the facility. This includes the design of engineering systems and networks for power supply, heat supply, water supply and sanitation, ventilation and air conditioning and security systems.

Fire extinguishing technologies are among the priority safety systems within the fire protection complex, especially for industrial or production facilities. Factories, production workshops, warehouses, premises with storage and circulation of highly flammable and combustible liquids are areas of increased danger, which should be equipped with effective fire extinguishing installations.

Engineering companies look for partners or contractors that will do their job perfectly. Therefore, the ideal counterparty for an engineering company:

- completely leads the project (works on a fire extinguishing system from concept to commissioning)

- provides a set of equipment (rather than individual parts under separate contracts from different plants)

- conducts installation supervision and commissioning, participates in putting the fire extinguishing system into operation

- performs maintenance works of the system in the warranty and post-warranty period

Pozhneftehim carries out all these works and tasks. We are one of the few companies in the Russian market that can provide the full cycle project maintenance.

Why Pozhneftehim?

- Russian manufacturer. We produce the whole range of equipment and foam concentrates for fire extinguishing systems for various purposes considering individual characteristics of the facilities.

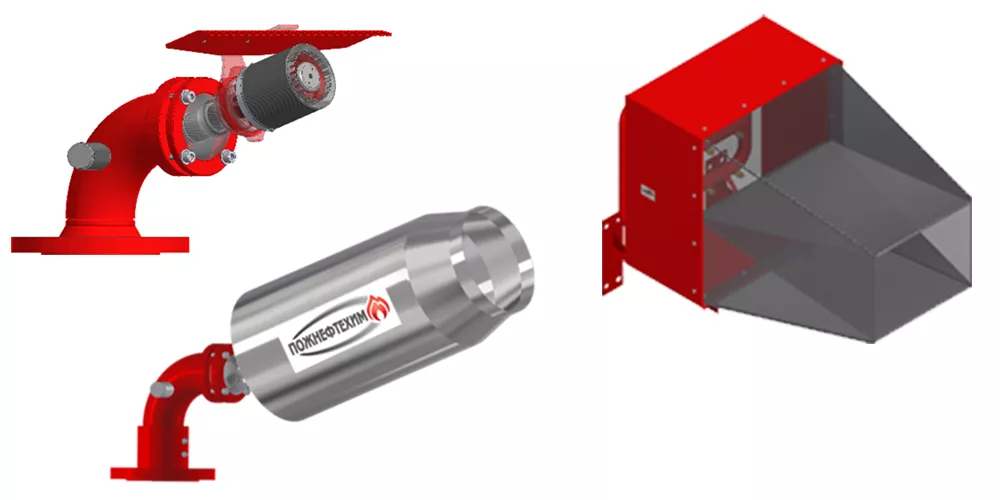

- We supply a “fire extinguishing system” rather than individual units (manufacturing and delivery of the entire list of basic fire equipment and foam concentrate, which underlies fire extinguishing, cooling or water curtain technology)

- We participate in the development of design solutions (concepts of fire protection, the technological part of the project, calculations, technical requirements, questionnaires, typical design solutions, installation drawings, etc.)

- We participate in commissioning not only equipment, but the whole SYSTEM, we provide for arranging preliminary and acceptance tests

- We suggest including measures that confirm products’ compliance with regulatory and design parameters in the Manufacturing and Supply Agreement

- We are a company that takes responsibility for the fire extinguishing system at the facility (to the extent of the fire extinguishing technology)

- We provide technical support for the fire extinguishing system during operation

What risks arise at the design stage of fire extinguishing systems?

It is known that questions regarding fire extinguishing technology often arise at the stage of design documentation coordination. It is important to assess the fire safety risks, design a project in accordance with applicable standards and rules, and choose a partner who is experienced in the field of providing fire extinguishing solutions for such facilities.

Pozhneftehim works both with new builds and renovated industrial facilities. The concept of fire protection is developed at the initial stage. If it has already been developed by another company, the design solutions should be checked for compliance with the requirements of the current fire safety legislation.

Then the Fire Protection Concept is developed. It contains a description of the main technical solutions for fire protection including the main parameters and algorithms of fire extinguishing systems and installations, structural diagrams. The concept is needed in order to subsequently prepare a technical task based on it.

How to choose a supplier and manufacturer of products for fire extinguishing systems?

On the Russian market there are many manufacturers and suppliers of products that can be used for fire extinguishing according to documents. The tender system allows to purchase equipment and foam concentrates according to the low price criterion without checking the accuracy of the certificate information and the operability of the equipment itself.

Saving on equipment that is responsible for the safety and stability of production is not feasible.

We believe that the main asset of any security system is the high quality of its components. Cheap materials and simplified copied technologies will affect the operation of the whole system and the level of industrial safety of the entire facility.

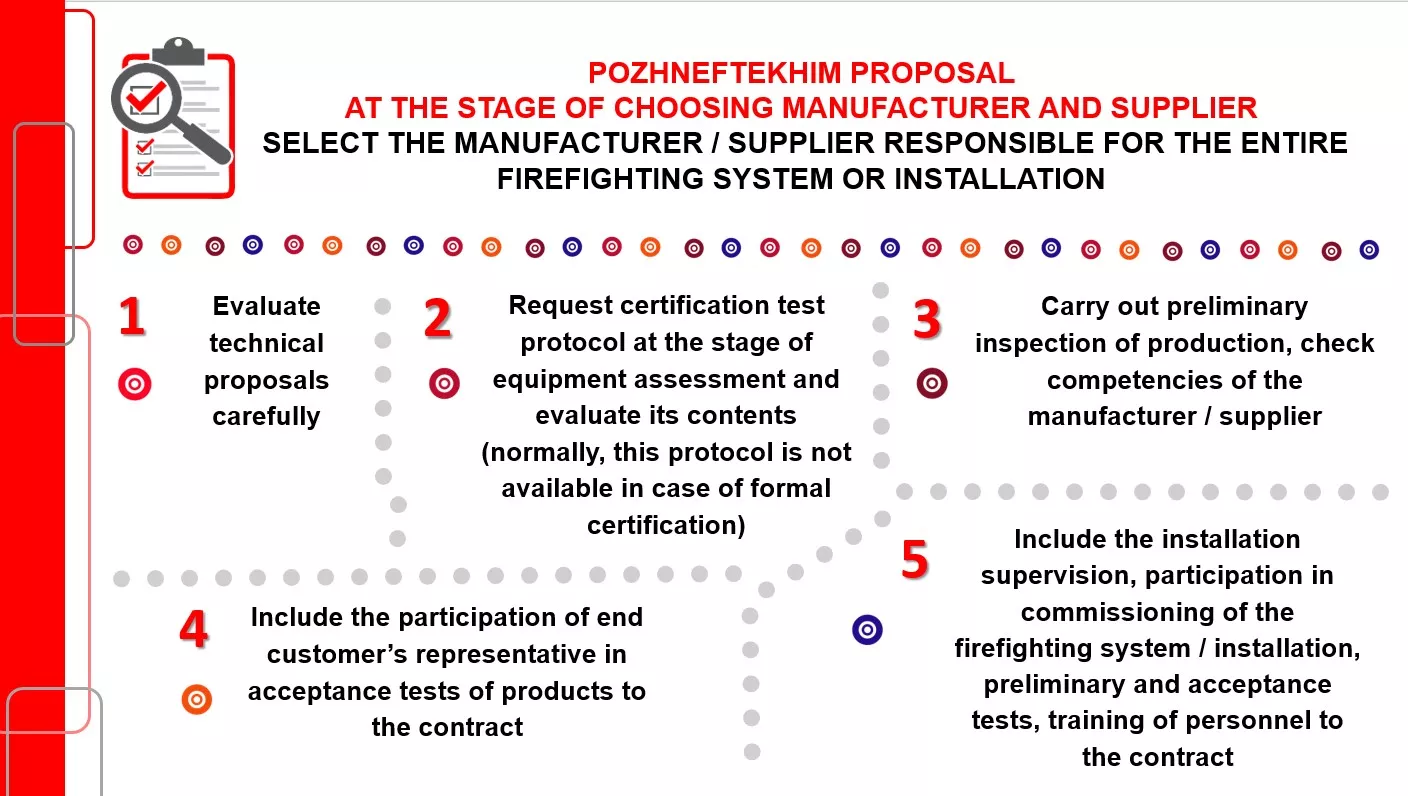

When choosing a manufacturer and supplier of products for fire extinguishing systems, attention should be paid to several parameters. Ask the counterparty two questions:

- How can we verify that equipment and foam concentrates comply with the technical description in the attached data sheets? Is it possible to participate in equipment testing to verify its performance? Is the product precisely resistant to high temperatures while the foam concentrate is not supplied?

- Does the manufacturing company take responsibility for the performance of its products and participate in acceptance tests? Is the company ready to conduct staff training at the facility?

Another important aspect concerns the labor costs of an engineering company to create a fire extinguishing system and fire protection. Is it convenient for the project team to work with a large number of contractors and suppliers of fire products?

If yes, then the risk that any difficulties that arise during the commissioning process may turn out to be unsolvable should be taken for granted, because it will be difficult to find the cause of inoperability without engaging external experts. Each manufacturer will claim that the equipment it supplies is in good condition. The performance of the entire system can only be guaranteed in advance by the supplier that provides the components for the entire fire extinguishing system.

Founded in 2004, a Russian manufacturer of fire equipment and foam concentrates Pozhneftehim now has more than 14 types of products for fire extinguishing. We know how to keep project on track from design to commissioning, and our systems and equipment are used in large industrial projects including especially hazardous petrochemical facilities.

Pozhneftehim additional services for full cycle projects

Pozhneftehim invites the Customer’s representative to participate in individual equipment tests at a certified hydraulic test stand. The stand is located at Pozhneftehim domestic production facility in Donskoy, Tula Region. The company uses the training ground to develop new types of equipment and to test the operability of fire extinguishing systems and their components.

In addition to organizing its own individual tests, Pozhneftehim develops methodologies and conducts acceptance and periodic tests of fire extinguishing systems at the facility. The company may also participate in the development of regulatory operational documentation for the system.

Pozhneftehim conducts training of specialists at the facility and organizes Advanced training courses with fire tests in-house. The participants in the courses are specialists from design organizations, labor protection managers, and representatives of customer companies. Training is conducted on the basis of a license from the Ministry of Education. For more information please follow this link https://www.pnx-spb.ru/en/napravlenia/kursy-povysheniya-kvalifikatsii/

Other news

The automated on-spot loading station (AUTN) is an automated technological facility for filling rail car tanks with liquid hydrocarbons in on-spot mode with movement of tanks for filling by a special shunting device which is an integral part of installation.

Production of equipment for firefighting systems

The customized production of firefighting equipment, the packaged supply of fire fighting installations (equipment + foam concentrate), supervised installation, start-up and commissioning of firefighting systems and installations.

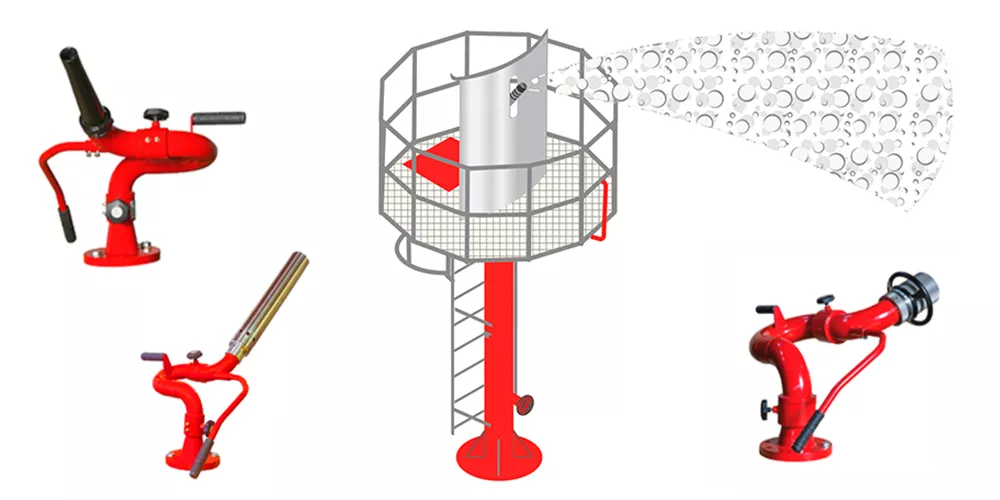

Foam fire extinguishing. Pozhneftehim foam fire extinguishing installations

Foam fire extinguishing is a set of actions to eliminate fire. A foam or a wetting solutions are used as a fire extinguishing agent in foam fire extinguishing systems and installations.

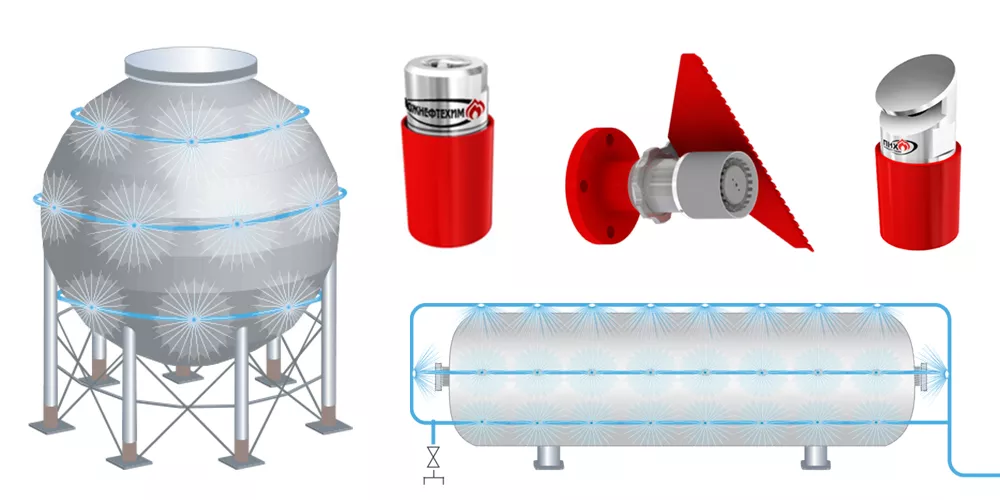

Tank farm facility: firefighting systems

The update of regulatory framework in the field of fire safety and the design of fire extinguishing systems affects both the objects under construction and the existing facilities.

Pozhneftehim offers comprehensive solutions for fire protection of oil depots. The company designs fire extinguishing systems and develops Special technical conditions (STU) for hazardous industrial facilities: warehouses for highly flammable and combustible liquids, tank farms, railcar and truck loading / unloading racks.

Pozhneftehim. Production of high expansion foam generators

Pozhneftehim has been producing Favorit high expansion foam generators since 2010. The company provides comprehensive supplies of fire extinguishing units with high expansion foam generators (equipment + foam concentrate), as well as installation supervision, commissioning and maintenance at the customer’s site.

Water spray systems for fire protection of storage tanks, process vessels. Fixed water spray systems

Water spray is subject to the requirements of GOST R 12.3.047-98 Occupational Safety Standards System. Fire Safety of Technological Processes.

Water fire extinguishing. Pozhneftehim Water fire extinguishing installations

Water fire fighting is the most common way to extinguish fires.

Comments

Add first comment

Add comment

Add comment