11.03.2019

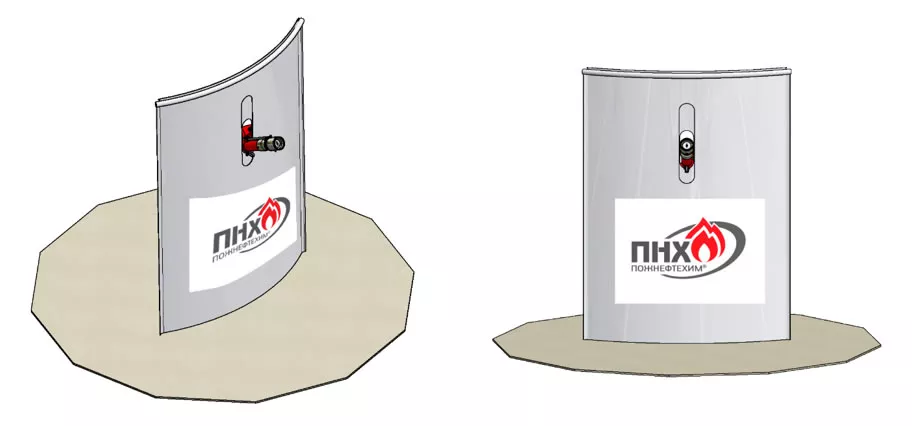

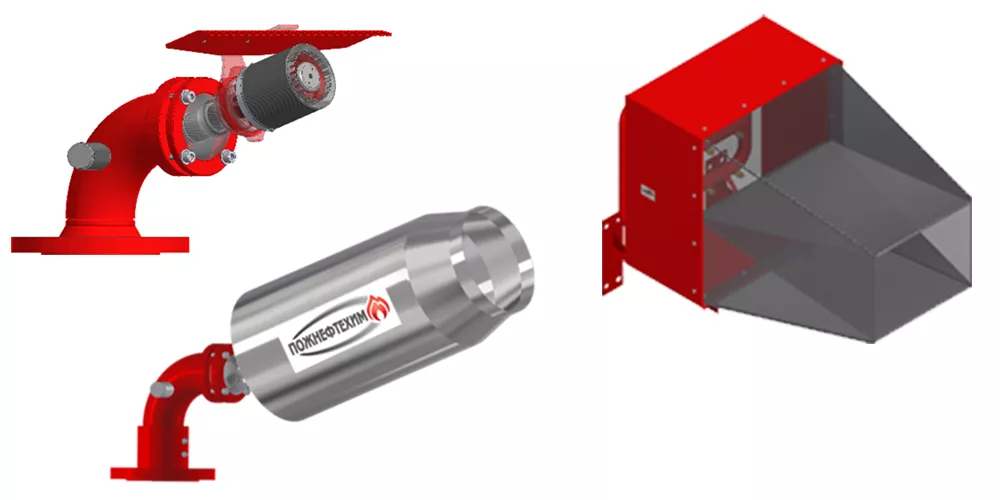

Pozhneftehim has completed R&D to create a water heat-protective screen for its own production. Developments in this area were in 2017-2019 with the involvement of specialists from scientific and educational institutions. According to the test results, the Pozhneftehim water heat-protective screen was found to provide the normative permissible parameter of the heat flux even in conditions significantly exceeding the limit values of exposure to fires of highly inflammable and combustible liquids, as well as LPG.

Regulatory rationale for the use of the water heat-protective screen

Water heat-protective screens are used in accordance with construction regulations (Sets of Rules) SP 155.13130, SP 231.1311500.2015, SP 326.1311500.2017. The use of heat-protective screens is also provided for in the draft revision of the new SP “Loading racks for highly inflammable, combustible liquids and liquefied petroleum gases at oil refining and petrochemical enterprises. Fire Safety Requirements".

The advantage of the Pozhneftehim water heat-protective screen over analogues is in its simple design combined with high strength and reliability. The water heat-protective screen can be used in conditions of variable temperatures (negative ambient temperatures at the moment of fire). In addition, the new waterfilm screen is effective at heat flux of high limits.

With parameters of the heat flux intensity up to 100 kW, the Pozhneftehim water heat-protective screen provides a heat flux parameter of not more than 5 kW. This value complies with regulatory requirements and significantly exceeds the established limit values for the effects of fire heat fluxes.

The intensity of thermal radiation according to GOST R 12.3.047 - 2012

Typical maximum permissible values of the intensity of thermal radiation for various degrees of human damage and damage to materials are specified in GOST R 12.3.047 - 2012. The following is the data (table B.2).

Degree of injury |

Typical maximum permissible values of the intensity of thermal radiation, kW/m2 |

|

No negative effects over a long time |

1,4 |

|

Safe in canvas clothing |

4,2 |

|

Unbearable pain after 20-30 s |

7,0 |

|

Ignition of wood, painted with oil paint on a planned surface; ignition of plywood |

17,0 |

|

Unbearable pain after 3-5 s |

10,5 |

|

Ignition of rough surface wood (humidity 12%) at a long-term exposure of 15 minutes |

12,9 |

|

Sergey Panov, the Pozhneftehim Technical Director points out:

“The Pozhneftehim water heat-protective screen belongs to waterfilm screens of a fundamentally different type. Its capabilities are at least two times higher than the limit values established by the norms for the effects of fire heat fluxes. The potential for continuing R&D in this area lies in increasing the value of the existing heat flux”.

On development of the Pozhneftehim water heat-protective screen

The R&D on creation of the Pozhneftehim water heat-protective screen was run in several stages. At the first stage, specialists carried out numerical simulation of the processes of heat flow influence on the screen, taking account of different water supply parameters. Thus, the initial data for the design development were obtained.

After the development of design and the production of prototypes, the research began to achieve required parameters of the water flow. These parameters included the thickness and uniformity of the water film, the flow rate, minimization of water flow to values that do not affect the hydraulic parameters of fire monitors, water supply pressure.

The R&D final stage was the research in an accredited testing laboratory using a special fire furnace. According to the test results, the parameters of the heat flux intensity were determined as 100 kW (the highest value the furnace can provide) and the heat flux parameter behind the water heat-protective screen was 5 kW at most. The limit parameters of the WHS operation were not set due to the limited technical characteristics of the test equipment.

These characteristics should be compared with the data of the heat flux density during the jet outflow of LPG and during the burning of the LPG spill. Below are the tables from the Recommendations of the Federal State Institution VNIIPO EMERCOM of the Russian Federation “Loading racks for highly inflammable, combustible liquids and liquefied petroleum gases. Fire Safety Requirements”, Moscow, 2007.

Table 1. The heat flux density during the LPG jet exhaust burning action, kW/m2

LPG flow rate, kg/s |

Distance to a flame torch, m |

||||||||||

5 |

10 |

15 |

20 |

25 |

30 |

40 |

50 |

60 |

70 |

80 |

|

1 |

8,4 |

4,2 |

- |

- |

- |

- |

- |

- |

- |

- |

- |

2 |

12,6 |

6,3 |

5,6 |

2,8 |

- |

- |

- |

- |

- |

- |

- |

3 |

14,0 |

7,8 |

7,0 |

4,2 |

- |

- |

- |

- |

- |

- |

- |

5 |

- |

9,2 |

8,4 |

7,0 |

4,2 |

- |

- |

- |

- |

- |

- |

7 |

- |

11,1 |

10,5 |

8,4 |

7,8 |

4,5 |

1,7 |

- |

- |

- |

- |

10 |

- |

- |

12,6 |

10,1 |

9,2 |

7,0 |

5,5 |

2,4 |

- |

- |

- |

15 |

- |

- |

- |

13,1 |

11,9 |

9,8 |

7,0 |

5,9 |

4,2 |

- |

- |

20 |

- |

- |

- |

- |

- |

11,9 |

8,8 |

7,3 |

6,3 |

5,7 |

4,2 |

Table 2. The heat flux density during the LPG spill burning action, kW/m2

Combustion area, m2 |

Distance to flame front, m |

||||

2 |

5 |

10 |

15 |

20 |

|

1 |

3,8 |

- |

- |

- |

- |

2 |

7,0 |

4,2 |

- |

- |

- |

3 |

11,1 |

7,0 |

4,2 |

- |

- |

5 |

14,0 |

8,1 |

4,9 |

2,1 |

- |

7 |

16,5 |

9,2 |

5,5 |

2,3 |

- |

10 |

18,0 |

10,5 |

6,3 |

3,1 |

- |

15 |

20,5 |

12,6 |

8,1 |

3,9 |

- |

20 |

30,0 |

24,0 |

11,1 |

5,6 |

2,4 |

100 |

75,0 |

40,0 |

11,0 |

6,0 |

2,8 |

150 |

82,0 |

45,0 |

14,0 |

8,0 |

4,2 |

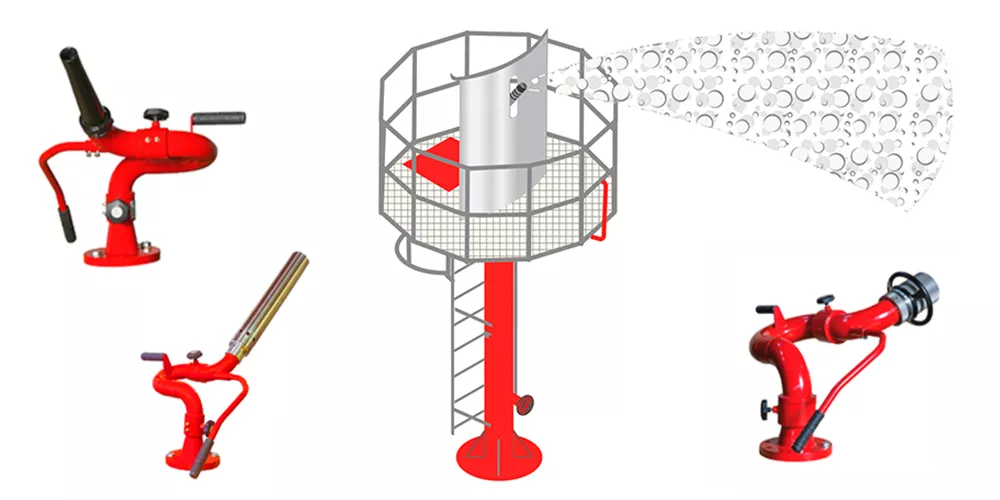

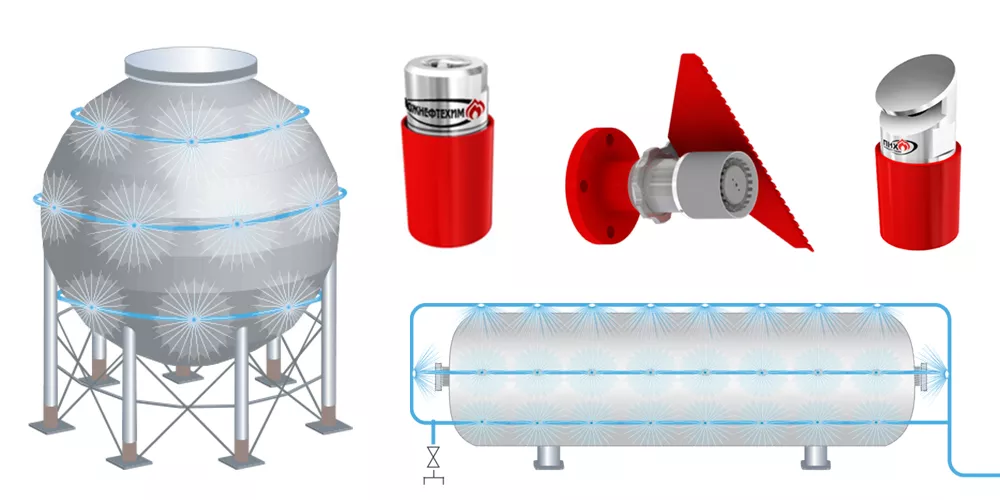

Taking into account the data of normative documents and technical characteristics of the Pozhneftehim water heat-protective screen, one can argue that the new development meets the requirements of the technical specifications and corresponds to the possible values of heat fluxes that occur during fires. The Pozhneftehim water heat-protective screen is able to reduce the intensity of thermal radiation of the flame and protect an operator of the fire monitor (firefighter) during the water supply to a burning object for cooling or extinguishing a fire.

Other news

POZHNEFTEHIM ON DESIGN OF WATER SPRAYING INSTALLATIONS WITH DELUGE SPRINKLERS ORK AND NRO

From May 31 to June 3, 2023, the XXXV International Scientific and Practical Conference "Actual problems of Fire Safety" was held within the framework of the salon "Integrated Safety" of the Ministry of Emergency Situations of Russia.

Pozhneftehim reports at NTS RMRS meeting

On November 23, 2022, the meeting of the Science and Technical Council of the Russian Maritime Register of Shipping (NTS RMRS) was attended by the heads of the Pozhneftehim Group: General Director Evgeniy Dmitrievich Veselov, Deputy Director Sergey Alexandrovich Panov and Head of R&D Yuri Konstantinovich Poteryaev.

Pozhneftehim developed STU on fire safety for EVRAZ industrial facility

Pozhneftehim, the manufacturer of fire extinguishing systems and developer of design documentation for fire safety of industrial facilities, has prepared Special technical conditions for the EVRAZ facility in the Tula region. The STU has passed necessary approvals in state bodies.

Pozhneftehim optimizes storage facilities

Pozhneftehim, a large Russian manufacturer of equipment and foam concentrates for fire extinguishing systems, continues to implement the strategy of lean manufacturing and optimization of production processes.

Reference of CC-7 on finalized works with Pozhneftehim Group

Pozhneftehim has received one more positive reference from customer. Specialists of the China National Chemical Engineering

Comments

Add first comment

Add comment

Add comment