06.08.2018 13:14:00

Photo: Pozhneftehim LLC © 2004-2018. Antifire bladder tank in a fire extinguishing block container.

Photo: Pozhneftehim LLC © 2004-2018. Antifire bladder tank in a fire extinguishing block container.

A bladder tank is a foam storage system that is common in the Russian market. The device plays a key role in the operation of the entire fire extinguishing installation. The firefighting capacity of the foam depends on the quality of the resulting solution (premix).

In Russia, bladder tanks of both domestic and foreign production are used. As of August 2018, all products are manufactured according to the specifications of their manufacturers. What this means, and how to reduce the risk of customers purchasing low-quality products? The answers you will find in the next section.

Bladder tank: purpose and functions in foam extinguishing installations

Bladder tanks are used at industrial facilities including production shops, warehouses, warehouse buildings and premises for storing combustible materials. Dispensing tanks are also used at especially dangerous facilities in oil and gas and petrochemical industries with the handling (storage) of highly flammable and combustible liquids.

Vertical bladder tank

|

Horizontal bladder tank

|

Double vertical bladder tank

|

The company Pozhneftehim, founded in 2004, specializes in the supply of equipment and foam concentrates for foam fire extinguishing installations of hazardous production facilities, mainly in the oil and gas and petrochemical industries. Therefore, we fully understand how important the performance of each element of the fire extinguishing system is. Especially the performance of bladder tanks that Pozhneftehim has been producing since 2010 under the Antifire brand.

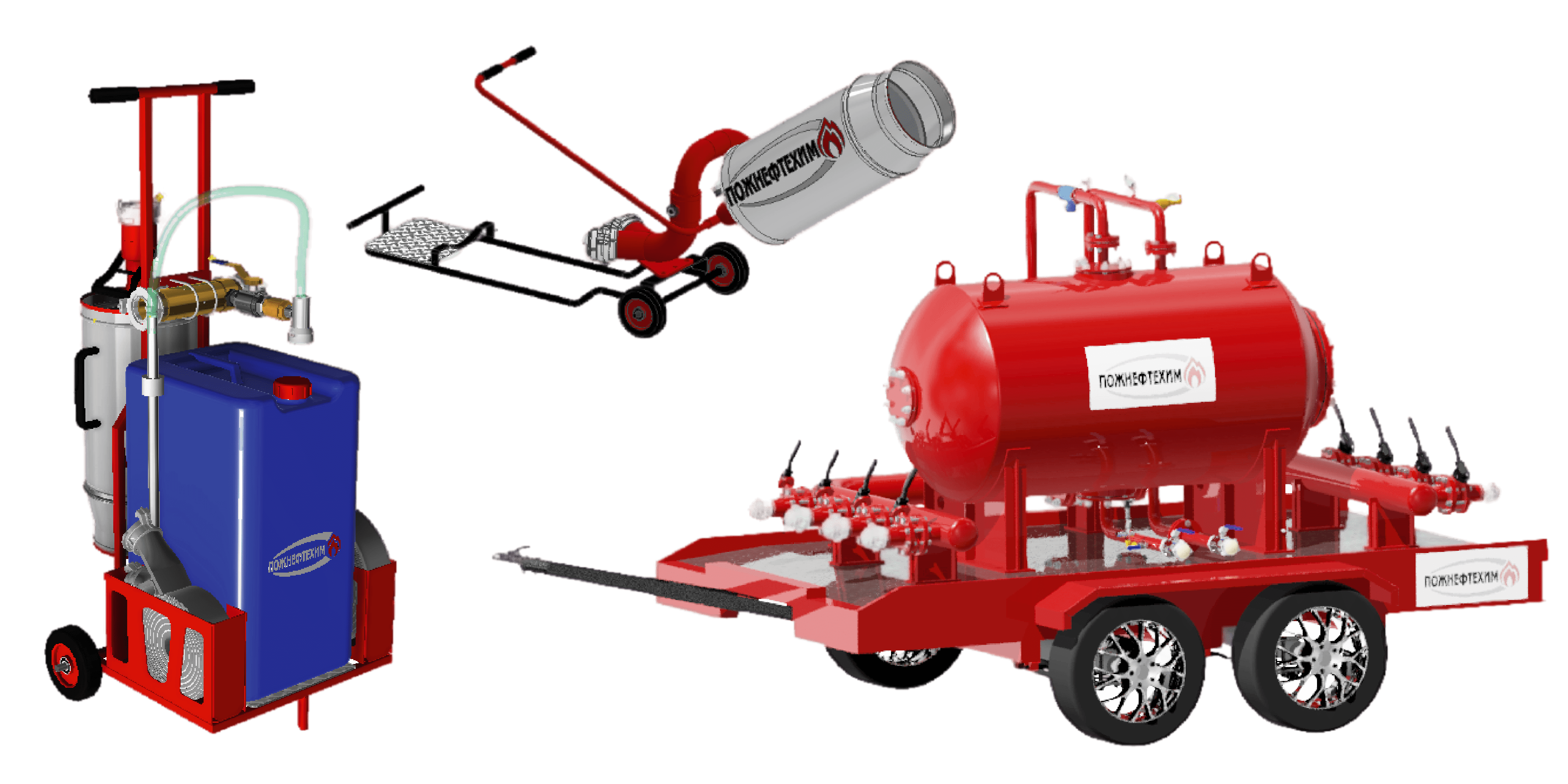

Figure 1. Antifire bladder tanks manufactured by Pozhneftehim

The bladder tank is designed to store and dispense the foam concentrate into the water stream to obtain a working solution of the foam concentrate. The working solution goes through the pipelines to foam generators or deluge sprinklers, which supply the air-mechanical foam into the fire zone.

We should note two conditions for the correct operation of the bladder tank:

- the premix contains exactly 1%, 3% or 6% of the foam concentrate in the volume (depending on its type), dosing tolerance is according to ISO/FDIS 7076;

- All structural elements of the bladder tank, especially the internal flexible container, are in good condition.

Let’s talk about the principle of its operation to understand the importance of fulfilling these conditions for the performance of the bladder tank.

How does a bladder tank work?

Figure 2. The main structural elements of the bladder tank manufactured by Pozhneftehim

During the system’s operation, water enters the dispenser (Item 1), along the supply line (Item 2), part of the water enters the cavity between the flexible container with the foam concentrate and the tank, then through the line (Item 4) the foam concentrate through the calibrated diaphragm (Item 3) enters the dispenser.

Dosing is provided due to the pressure difference at the inlet and outlet of the dispenser created by the diaphragm (Item 7). The dosing percentage is controlled by the calibrated diaphragm of the dosing device (Item 3). A drain valve (Item 8) is needed to drain the water from the inside of the tank when replenishing the supply of foam concentrate in the system through the filling line (Item 9). The system air removal valve (Item 10) is used to bleed air during refilling.

What you need to know about the bladder tank when purchasing?

When purchasing, installing and operating a bladder tank, it is necessary to objectively assess the quality of the product and understand the risks when purchasing a low-quality dosing system.

Bladder tanks today are not included in the number of products determined by GOST. They are produced according to the technical specifications (TU) of their manufacturers. Some of the items have available certificates of compliance with regulatory documents to which bladder tanks have no relation. Therefore, customers need to independently and carefully monitor the quality of the proportioning system for the foam fire extinguishing installation.

Pozhneftehim, a manufacturer of equipment and foam concentrates for fire extinguishing systems and installations of industrial facilities, proposes to use the following comparative table for procurement. It allows to objectively compare the quality of products from different manufacturers and choose the best option. So, manufacturers' technical proposals should contain the following information:

Parameters and quality indicators (according to the project or upon request of the client) |

Technical Proposal 1 |

Technical Proposal 1 |

Technical Proposal N |

|

|

|

|

2. Foam concentrate level control according to GOST R 50800 |

|

|

|

- manual - automated |

|

|

|

3. Internal anti-corrosion coating |

|

|

|

- technical justification |

|

|

|

- application regulations |

|

|

|

- certificate of conformity |

|

|

|

4. External coating |

|

|

|

- technical description |

|

|

|

- application technology |

|

|

|

- certificates of conformity for primer and paint. |

|

|

|

5. Material for manufacturing the main elements (type of steel) |

|

|

|

- tank |

|

|

|

- flexible container |

|

|

|

- piping arrangement |

|

|

|

- dispenser |

|

|

|

- dosing diaphragms |

|

|

|

6. Type and material design of components |

|

|

|

- ball valves |

|

|

|

- drainage valves |

|

|

|

- check valve |

|

|

|

- flow meter |

|

|

|

- flow signaling device |

|

|

|

- concentrate control valve |

|

|

|

- filter |

|

|

|

- pressure gauges |

|

|

|

- compressor |

|

|

|

- refilling pump |

|

|

|

7. Approval Documentation |

|

|

|

7.1 Certificate of conformity in the field of fire safety, certification test protocol |

|

|

|

7.2 Tank compliance with GOST 52630-2012 (declaration)) |

|

|

|

7.3 Availability of the manufacturer in the register of the National agency for welding control |

|

|

|

7.4 Availability of operational and supporting documentation |

|

|

|

- maintenance manual (mandatory); - passport of the vessel, drawn up in accordance with the requirements of section IV of paragraph 21 of TR TS 032/2013 "On the safety of equipment operating under excessive pressure". The passport should indicate the methodology, frequency and scope of the vessel control, the implementation of which will ensure the timely detection and elimination of defects (upon request); - certificates of quality and characteristics used in the manufacture of materials (upon request); - documentation for the inner coating of the tank, soil, enamel (upon request). |

|

|

|

7.5 The presence of a test stand at the production venue (the ability to demonstrate the operation of the product, taking into account the specified characteristics) |

|

|

|

7.6 Availability of service. Guarantees of installation and commissioning. |

|

|

|

7.7 Warranty on the storage of the foam concentrate in the tank |

|

|

|

7.8 Information on judicial practice, references |

|

|

|

Bladder tank: operation and manufacturer's guarantees

Departments of maintenance and operation services at the facilities should know the design features of the bladder tank, which affect its performance.

Bladder tank flexible container

Inside the bladder tank there is a flexible container in which the foam concentrate is stored. Pozhneftehim manufactures the bladder tank flexible container from the high-strength highpolon-neoprene material using special technology. Due to the minimum number of connecting seams and the use of high-quality polymer glue when connecting fragments of the tank in production, the probability of failure of the bladder tank without mechanical impact on it is practically reduced to zero. At the same time, the bladder tank remains a product not determined by GOST and the technology for manufacturing flexible containers for storing foam concentrates differs from one manufacturer to another.

Inside the bladder tank there is a flexible container in which the foam concentrate is stored. Pozhneftehim manufactures the bladder tank flexible container from the high-strength highpolon-neoprene material using special technology. Due to the minimum number of connecting seams and the use of high-quality polymer glue when connecting fragments of the tank in production, the probability of failure of the bladder tank without mechanical impact on it is practically reduced to zero. At the same time, the bladder tank remains a product not determined by GOST and the technology for manufacturing flexible containers for storing foam concentrates differs from one manufacturer to another.

Figure 3. Bladder tank flexible container. Illustration: Pozhneftehim LLC ©

The flexible container is the most vulnerable element in the design of the bladder tank. If the refilling technology is violated or the design parameters are violated during testing, it ruptures. Checking the integrity of the flexible container is provided using a drain valve at the bottom of the tank (Figure 2, item 8). If traces of a foam concentrate are observed when it is opened before the system starts to work, it means that the flexible container has a rupture.

However, if trial commissioning tests have passed, the foam solution will still fall into the cavity between the tank and the internal flexible container. During repeated starts, the solution enters through the water supply line into the tank outside the flexible container. Attempts by some manufacturers to verify the integrity of the flexible container by measuring pH are questionable. Checking the signs of the presence of a foam concentrate with the help of a drain valve on the tank does not provide a full guarantee of the product’s operability during operation.

It should be considered that even if the “flexible container” is “excluded” from the structure and the tank is filled with a foam concentrate, we will get the desired result during the tests. Water will flow into the foam concentrate and squeeze it into the line. A decrease in the concentration of the foam concentrate when mixed with water while observing the quality of the foam during the acceptance test is not possible, since the launch, as a rule, is quite short. Accordingly, even with a torn flexible container, the bladder tank will provide a foam solution. However, it’s very difficult to determine whether it is operating or not.

To check the tightness of a flexible container, it is necessary to completely disassemble the bladder tank and carry out a series of works to check the tank with air pressure. This is a time-consuming process and carrying it out regularly is problematic. Thus, the bladder tank, which has a large number of positive qualities, also has the quality of an "black box". At any period of operation of the bladder tank, the risks of using a non-operating product cannot be excluded.

Pozhneftehim recommends that, when purchasing and operating bladder tanks, the competent specialists of the manufacturer should be involved in the installation of the product, commissioning and acceptance testing. When purchasing a bladder tank, a reserve flexible container should also be included in the configuration. Employees at the facility responsible for the maintenance of industrial and fire safety systems should be trained with the assistance of the manufacturer. During the warranty period, you should interact with the manufacturer to eliminate the risk of damage to the product.

Diaphragms (washers) of a standard bladder tank. Operating parameters

Diaphragms (washers) are the main structural elements of the bladder tank. They are responsible for the dosing parameters. Diaphragms are installed in the dispenser and on the foam concentrate supply line (Figure 2, item 3, 7). The correct selection of the parameters of these elements determines the operating pressure range and the flow range at which the necessary volume concentration is ensured.

A bladder tank is a dosing system for a fire extinguishing agent. The effectiveness of the entire fire extinguishing system depends on its correct operation. Therefore, the technical parameters of the product must be treated carefully. As a manufacturer of equipment and foam concentrates for fire extinguishing units, Pozhneftehim organized a hydraulic stand at its own production site in the Tula Region. Thanks to the test bench, the company can check the quality of products and their performance with different technical parameters. Customers ordering the Antifire bladder tanks by Pozhneftehim get a product configured to the required parameters and have a factory test report confirmation. Only few manufacturers in the Russian market can provide similar guarantees.

Some imported bladder tanks, as well as products copied from an imported sample, indicate the flow range at an inlet pressure of 1.2 MPa. Pressure ranges are not shown. Change of the flow ranges at inlet pressures other than 1.2 MPa can only be determined during complex factory tests, which require bench equipment and an understanding of the operating modes of bladder tanks as part of foam fire extinguishing units. The manufacturer must indicate the relationship between the inlet pressure, the hydraulic losses on the dispenser and the operating range of flow rates, in order to guarantee the operability of the dispensing system for different parameters.

Pozhneftehim recommends buying bladder tanks from manufacturers of firefighting equipment which test their products at hydraulic test benches before selling. In order to improve the quality of the dosing system, Pozhneftehim recommends the use of a wide range of dispensers with automatic control. This measure will eliminate unstable dosing.

How to lower the cost of a bladder tank?

Simplification of the assessment of technical proposals and quality indicators ultimately leads to significant additional costs, problems with putting the fire extinguishing unit into operation. If we are talking about an industrial or production facility for which fire safety is essential, it is important that the elements of fire extinguishing units are of high quality. The stability of production and the safety of employees should be more important than small savings when purchasing components of security systems at tenders.

It is advisable to buy a bladder tank and a foam concentrate from one manufacturer. If you choose Pozhneftehim, it provides additional guarantees of the system's operability, as well as extended guarantees for the foam concentrate. Pozhneftehim has been producing Aquafom foam concentrates since 2011 and its product line includes more than 180 compositions of foam concentrates of S, AFFF, AFFF/AR, S/AR, WA types.

We hope that this material will allow the client to carry out a technical assessment of the quality of the proposed equipment at a sufficient level, and to avoid problems in the preparation, testing and commissioning of facilities, as well as significant additional costs for further operation.

Advanced training in fire safety and foam fire extinguishing systems

Pozhneftehim invites specialists from design organizations, engineering companies, construction and operating services to Advanced training courses. The topic: “Modern technologies of foam fire extinguishing at the facilities of the oil, petrochemical and gas industry”. The course program is available on the website of Pozhneftehim www.pnx-spb.ru. Contact our managers to participate in the courses.

Video https://www.youtube.com/watch?v=jWA5wTO2PE4&t=2s

At the Advanced training courses, we discuss the features of fire extinguishing systems, fire equipment and foam concentrates that are available on the Russian market, we demonstrate the operation of fire extinguishing systems of low, medium, high expansion with Aquafom foam concentrates of our production. The training is conducted by Pozhneftehim LLC under the License of the Ministry of Education of the Tula Region No. 0133/03315 dated September 30, 2016.

The article was published on the site ogneportal.ru

The article was prepared by specialists of Pozhneftehim LLC

Contact for further advice: +7 (499) 703 01 32, mail@pnx-spb.ru

Other news

The automated on-spot loading station (AUTN) is an automated technological facility for filling rail car tanks with liquid hydrocarbons in on-spot mode with movement of tanks for filling by a special shunting device which is an integral part of installation.

Production of equipment for firefighting systems

The customized production of firefighting equipment, the packaged supply of fire fighting installations (equipment + foam concentrate), supervised installation, start-up and commissioning of firefighting systems and installations.

Foam fire extinguishing. Pozhneftehim foam fire extinguishing installations

Foam fire extinguishing is a set of actions to eliminate fire. A foam or a wetting solutions are used as a fire extinguishing agent in foam fire extinguishing systems and installations.

Tank farm facility: firefighting systems

The update of regulatory framework in the field of fire safety and the design of fire extinguishing systems affects both the objects under construction and the existing facilities.

Pozhneftehim offers comprehensive solutions for fire protection of oil depots. The company designs fire extinguishing systems and develops Special technical conditions (STU) for hazardous industrial facilities: warehouses for highly flammable and combustible liquids, tank farms, railcar and truck loading / unloading racks.

Pozhneftehim. Production of high expansion foam generators

Pozhneftehim has been producing Favorit high expansion foam generators since 2010. The company provides comprehensive supplies of fire extinguishing units with high expansion foam generators (equipment + foam concentrate), as well as installation supervision, commissioning and maintenance at the customer’s site.

Water spray systems for fire protection of storage tanks, process vessels. Fixed water spray systems

Water spray is subject to the requirements of GOST R 12.3.047-98 Occupational Safety Standards System. Fire Safety of Technological Processes.

Water fire extinguishing. Pozhneftehim Water fire extinguishing installations

Water fire fighting is the most common way to extinguish fires.

Comments

Add first comment

Add comment

Add comment