CONTROL CABINET SHABD-102 FOR BLADDER TANK

TU 4200-038-72410778-2016

General

Purpose and scope

ShABD-102 is an control cabinet for the bladder tank. It is designed to measure, display, archive information about the foam concentrate level and to provide signals on remaining volume in real time to the automatic fire extinguishing control system. ShABD can be used with all types of bladder tanks with a volume of 200 to 24,000 liters.

The ShABD operation allows you to comply with SP 5.13130.2009 paragraph 5.9.23, 12.3.1.

The control cabinet ShABD-102 for bladder tank controls the level of the foam concentrate inside the tank and provide the following information:

- by analog signals 4 ... 20mA;

- by discrete signals when a preset level is attained;

- in digital format via RS-485 interface.

Distinctive advantages

- liquid crystal text display;

- information output to the ASUTP (automatic process control system) upper-level control system is effected using various types of signals (relay, analog, digital), which makes it possible to connect the control cabinet of the bladder tank to any type of equipment;

- convenient placement of elements to facilitate installation and repair work;

- password protection of settings against unauthorized access;

- archive of events;

- use of flowmeters with any value of a pulse signal.

Specifications

Key Specifications

| Indicator name | Indicator value |

| Supply voltage from the alternating current main, | V 90-264 (rated 220 V) |

| Current frequency, Hz | 50 |

| Power consumption, W, max | 30 |

| design | IP 65 |

| Overall dimensions (WxHxD) excluding cable entries, mm | 400х400х200 |

| Weight, kg, max | 5 |

Option package ShABD -102

ShABD package includes:

| ShABD -102 control cabinet | 1 pc. | Cable MKESHVng (A)-LS 1х2х0,75 | 10 (20)* m |

| Pressure sensor 0-0.1 MPa, output 4…20mA | 1 (2)* pcs. | Cable OVEN KS-1 | 1 pc. |

| Safety valve | 1 (2)* pcs. | Cable tags | 10 pcs. |

| Counter flowmeter | 1 (2)* pcs. | Cable tie | 10 pcs. |

| Reed sensor | 1 (2)* pcs. | Relay 24V DC | 1 pc. |

* Options depend on the number of controlled tanks.

Для просмотра полного описания технических характеристик отправьте заявку или войдите под своим профилемInstallation and Connection

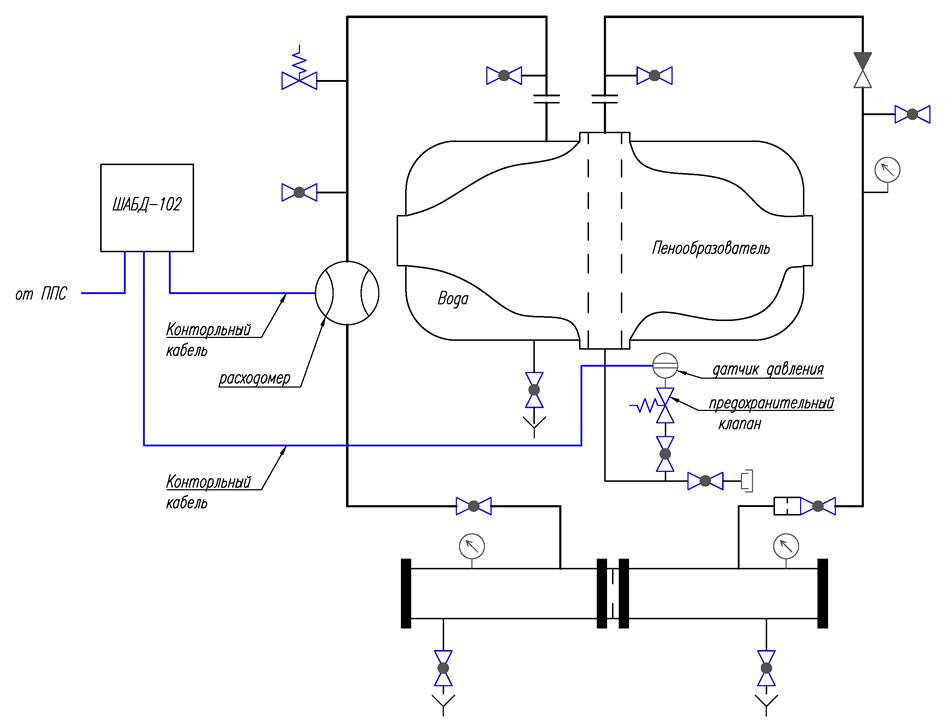

Schematic diagram of the ShABD installation on the bladder tank

The power is supplied with a copper cable VVGNG-FRLS 3x1.5, or similar. Pressure sensors are connected by MKESHvng (A)-LS 1x2x0.75 cable, which is included in the delivery package. Reed flowmeter sensors are connected directly to the control cabinet (2 m long). If the length has been increased, a control cable, for example, MKEShng (A)-LS 1x2x0.75, or similar can be connected via a terminal box.

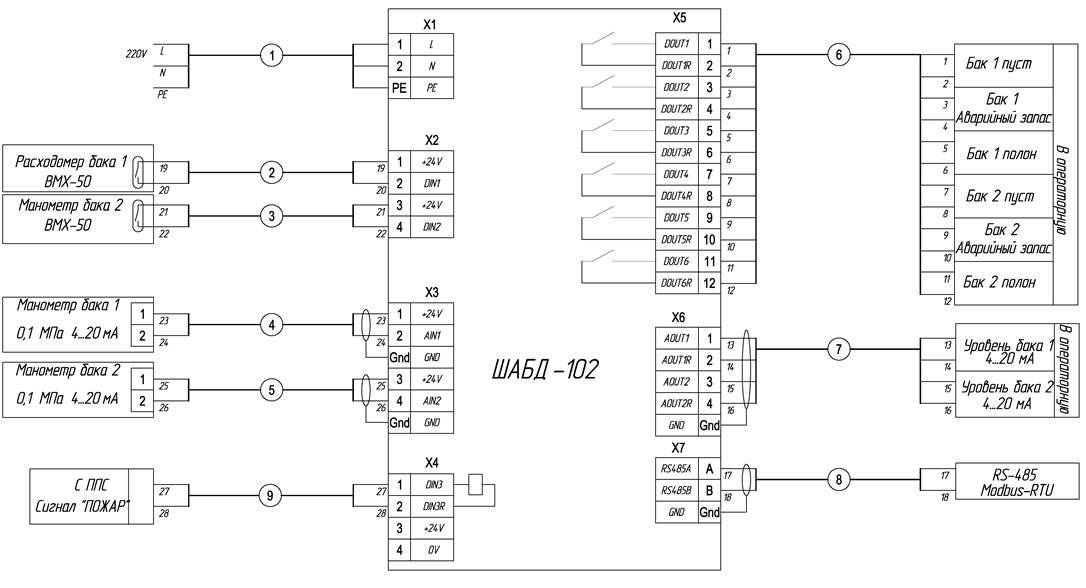

External connection diagram for ShABD-102 (when installed on a double bladder tank)

Operation description

The foam concentrate level during refilling is controlled indirectly, using a pressure gauge integrated in the foam concentrate filling line, and a flow meter with a pulse signal. Switch to the proportioning mode occurs when a signal is issued on the beginning of the extinguishing from the fire panel or from other devices. The signal voltage can be 24 DC or 220 V AC (effected by installing the appropriate relay included in the delivery package while installing the system).

The text liquid crystal display located on the front panel of the cabinet displays the following information:

- current operating mode;

- the amount of foam concentrate in liters, the volume in percent;

- current date, time;

- LEDs display the signals "tank full", "emergency reserve", "tank empty" for each tank. The settings for triggering of signals “emergency reserve” and “tank empty” in percentage can be set from the menu.

Information output to the ASUTP upper-level control system is effected using various types of signals (relay, analog, digital).

Relay outputs

There are 3 relay outputs for each tank to give out the following signals:

- “tank full” when the level of foam concentrate in the tank is more than 95%;

- “emergency reserve” when the level of foam concentrate reaches the emergency level (60% by default);

- "tank empty" when the level of foam concentrate has decreased to a minimum level (20% by default). Analog outputs).

Analog outputs

The analog outputs give the tank level in 4 ... 20 mA format.

Digital outputs

Connection via RS-485 allows receiving all parameters from the control cabinet, as well as to change settings. Communication is via an OPC server using Modbus RTU, Modbus ASCII, ARIES, GateWay protocols. Protocol selection is automatic.

ShABD maintains an archive of events containing the last 5 system starts. The date and time the system was started, the amount of foam concentrate and the flow rate are saved.

The password on the setting menu allows restricting unauthorized access to the ShABD-102 settings.

The device is maintenance-free, it is calibrated once during installation and refueling.

Upon activating the extinguishing system, the operator will have to put the device into the “refilling” mode during refilling.

Operation ShABD-102

Preparing the tank for operation

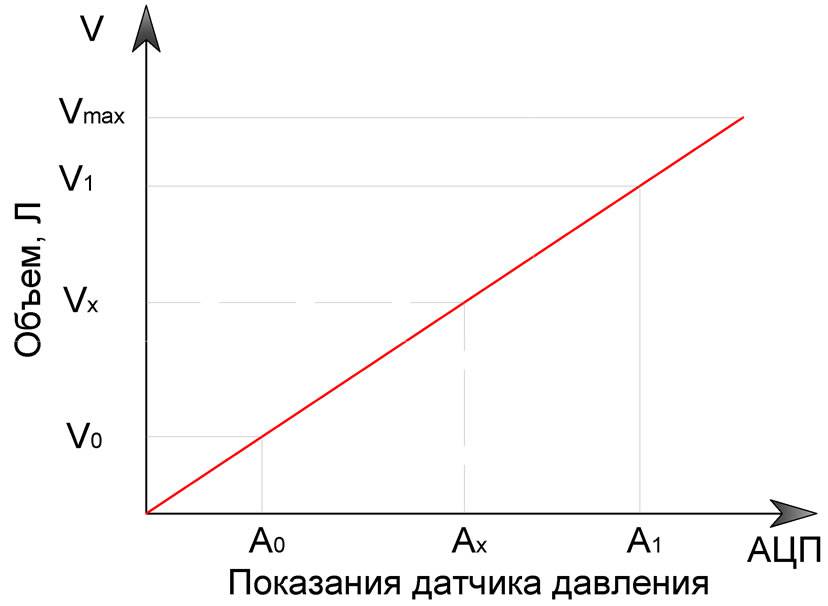

Calibration shall be performed at the first refilling of the bladder tank. For this end, ShABD -102 must be switched to the “refilling” mode. Then you need to set two points on the graph, comparing the volume of the empty tank with the readings of the ADC (analog-to-digital converter) of the pressure sensor and the volume of the tank filled with a known amount of foam concentrate with the corresponding pressure sensor reading. A pressure sensor is installed on the foam concentrate feed line. Whilst calibrating, the water supply lines from the proportioner must be shut off, the breathing valve above open. When refilling is over, shut off the breathing valve, close the foam concentrate filling line.

Volume calculation algorithm, where:

V0- minimum tank volume (tank is empty);

Vmax – maximum tank volume (tank is full);

Vx – current volume of foam concentrate in the tank;

V1 – some known volume poured into the tank (for calibration);

А0 –ADC indications corresponding to the “tank empty” level;

Ax –current ADC readings.

The bladder tank during refilling is in a standby mode.

Refilling mode

When the device is in the “refilling” mode, the display shows the current operating mode, the level of the foam concentrate in the bladder tank in liters and percent, the current date and time. The device calculates the tank volume based on the readings received from the pressure sensor.

Fire mode (proportioning)

During a fire, a “fire” signal should be sent to the ShABD, thereafter the pumps are started/the water supply valves open, the valves open to the tank from the proportioner. The control cabinet switches to the "proportioning" mode, saves in memory the volume of the foam concentrate available in the tank. During extinguishing, the flow rate of the foam concentrate is calculated according to the flow meter. After the fire is extinguished, it is necessary to shut off the valves for supplying water to the tank and those supplying foam concentrate, and to remove the “fire” signal. ShABD saves in the archive the consumption made during the extinguishing process and switches to the “standby” mode, showing on the display the current volume of the foam concentrate. When the extinguishing system is reactivated again, the cabinet switches back to the “proportioning” mode, continues to calculate the remaining foam concentrate and creates the next entry in the archive.

Refilling

Foam concentrate filling algorithm after the proportioning system is triggered:

1. Drain water from the tank by opening the water drain valve and opening the breathing valve.

2. Switch the ShABD to the “refilling” mode. In this mode, the tank will receive information about the volume in the tank from the pressure sensor.

3. Refill with a foam concentrate.

4. Close the breathing valve and the water drain valve.

5. Take the ShABD to the "standby" mode.

The bladder tank is ready for operation.

Памятка по выбору бака-дозатора для отдела закупок (pdf, 7.2 Mb)