AIRCRAFT HANGARS. HANGAR FIRES AND FIREFIGHTING SYSTEMS

Aircraft hangar is protected by an automatic fire extinguishing installation. The choice of fire equipment and foam concentrates depends on the method of firefighting.

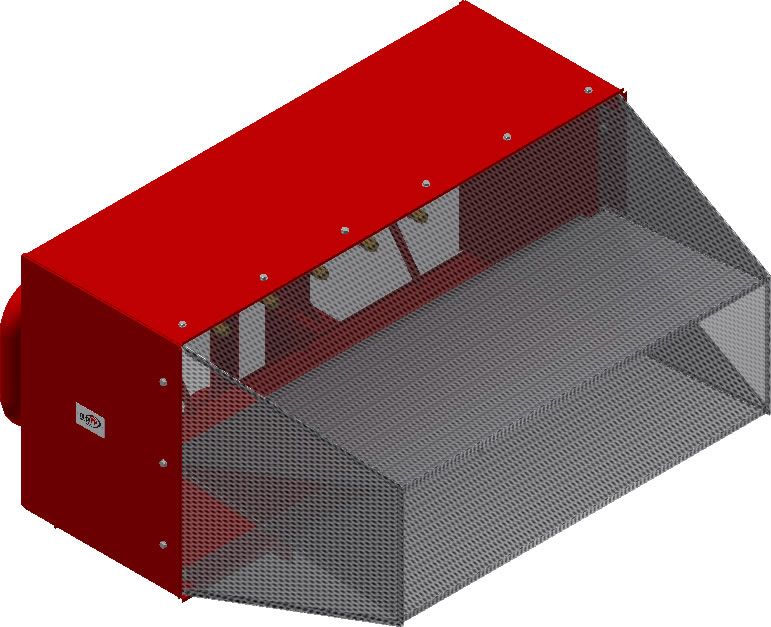

The cubical firefighting in a hangar involves the use of high expansion foam generators

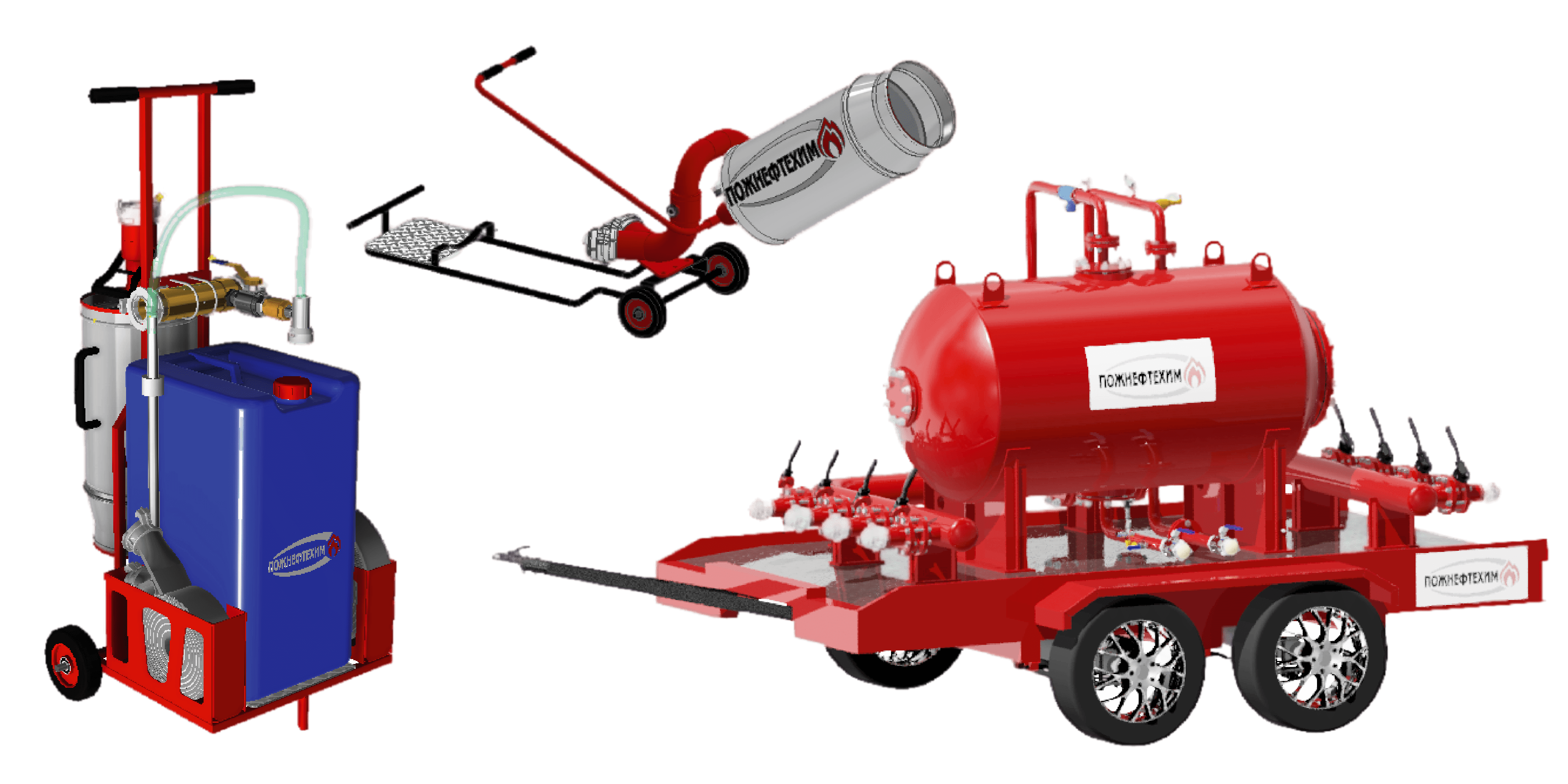

The surface method of fire extinguishing in hangars (by area) requires low- or medium expansion foam generators. Antifire universal water/foam nozzles or Turbopen universal foam generators manufactured by Pozhneftehim are used.

When choosing a fire extinguishing system and foam concentrate, we recommend consulting a specialist.

Choose your fire extinguishing system

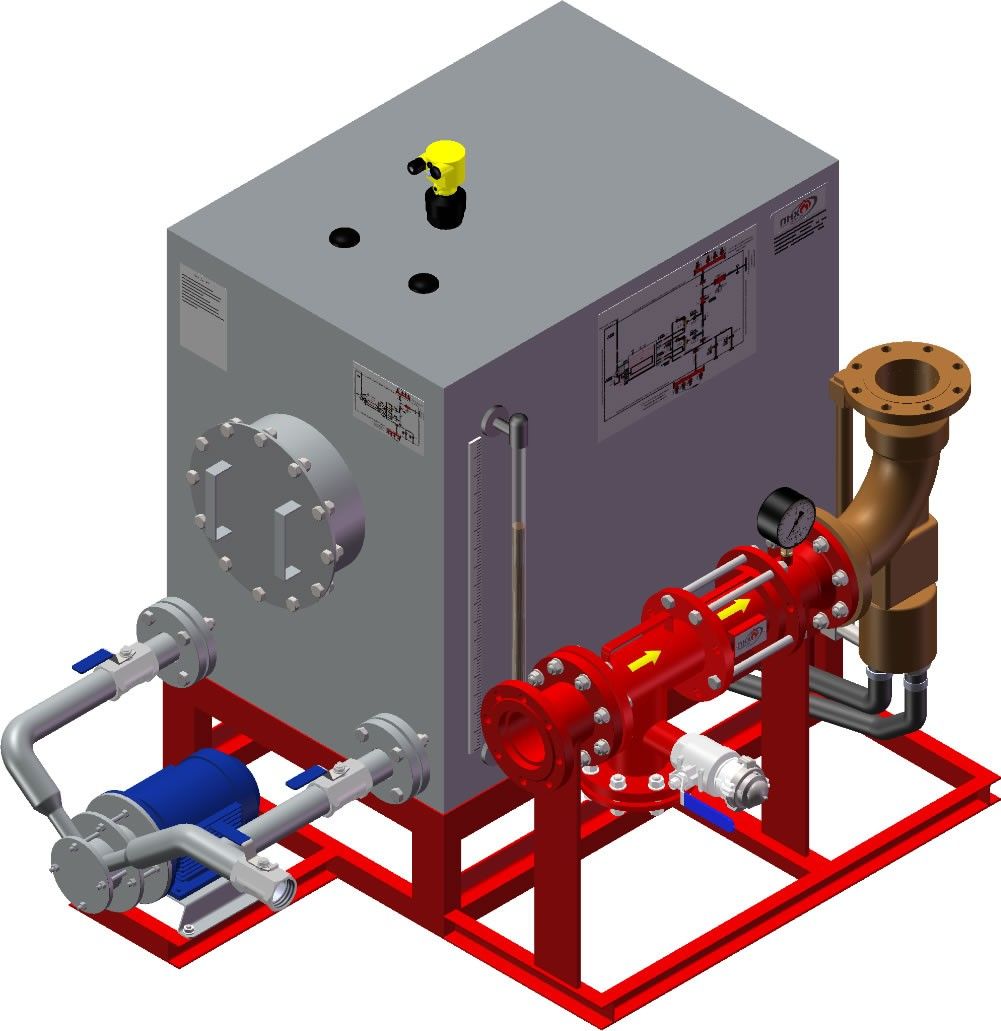

Foam concentrate storage and proportioning system (SKhDP)

Foam concentrate storage and proportioning system (SKhDP)

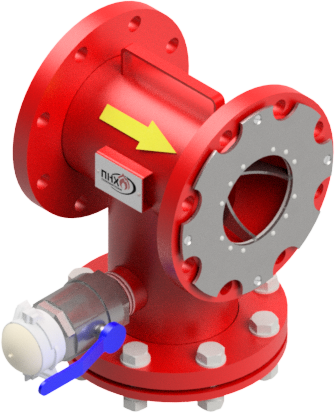

Tauer universal fire filter (PFU)

Tauer universal fire filter (PFU)

Favorite ejection foam generator (GVPE)

Favorite ejection foam generator (GVPE)

Fire safety of hangars and aircraft

During development of a firefighting installation for aircraft hangars, one should take into account the rapid fire development due to the large amount of solid combustible materials, aviation fuel and other combustible liquids, and a low degree of fire resistance of partitions.

Typically, aircraft are located in aircraft hangars without aviation fuel in tanks, however, a certain amount of fuel remains in the fuel system. In addition, many technical fluids in an aircraft are also flammable.

The fire load of aircraft cabins includes plastics, which, when burned, emit highly toxic substances (hydrocyanic acid, hydrogen chloride, carbon monoxide, cyanide vinyl, acrolein). These substances affect the nervous system, visual and respiratory organs of a body (immediately impair vision, lachrymation, suffocation, vomiting, convulsions).

Chassis fires are dangerous because the flame generated by burning hydraulic fluid and rubber directly affects aluminum alloys of aircraft wing and skin, since the aircraft and helicopters chassis are located either under the wing or under the fuselage. The main aluminum alloys of the wing and skin of the aircraft have a low critical temperature (about 250 °C) and a low melting point (≥ 520 °C for alloy D16). In this regard, in the event of the combustion of hydraulic fluid and rubber, a decrease in the mechanical strength of these alloys and their rapid destruction can occur. Since fuel tanks are located in the wings and center section of the aircraft, the destruction of the structure leads to a sharp increase in the size of the fire and its intensity.

The combustion of fuel, brake fluid, rubber and other materials ignites magnesium alloys used to make brake drums, arms, brackets, parts of fuel, oil, and hydraulic systems of aircraft and engine.

With the high reaction temperature (~ 3000 °C) the combustion zone of magnesium alloys is distinguished by a brightly glowing spot against the background of the “low temperature” flame of other substances and materials. Due to such a high temperature, burning sections are melted and heat can get into the space protected by the structure. This will cause new fires. When magnesium alloys are ignited in one place, gradual melting and ignition of the boundary areas occurs. The combustion area increases until combustion covers the entire surface of the burn out structure.

Automatic fire extinguishing systems for aircraft hangars

The requirements for automatic foam fire extinguishing installations are contained in the following regulatory documents:

- GOST R 50800-95

- GOST 12.3.046-91

- SP 5.13130.2009

- SP 10.13130.2009

- VNTP 11-85 (MGA) Departmental norms for technological design of aviation technical bases at airports

- Fire protection and firefighting in transport. M .: GPS Academy - 2006

- Recommendations for the design of automatic foam fire extinguishing installations in modern hangars. M.: 1980

- Ensuring fire safety at aerodromes of civil aviation. Jafarov M.A. M .: Transport - 1987

To assess the technical level of domestic standards, the following documents were studied and analyzed:

- Engineering Technical Letter (ETL) 02-15: Fire Protection Engineering Criteria - New Aircraft Facilities;

- UFC 4-211-01 Unified facilities criteria (UFC). Aircraft maintenance hangars.

It is necessary to provide an automatic fire extinguishing installation according to table A.3 of SP 5.13130.2009 and paragraph 9.4 of VNTP 11-85 in aircraft hangars.

The type of automatic fire extinguishing installation, the method of extinguishing, the type of fire extinguishing means, the type of equipment for automatic firefighting installations are determined by the design organization (clause A.3 of SP 5.13130.2009).

There are several approaches to extinguishing a fire in hangars - premises where aircraft are placed:

- The cubical method of extinguishing a fire with generators of high expansion foam;

- surface method of extinguishing a fire with generators of medium and low expansion foam.

When choosing a method of extinguishing a fire in a hangar and the type of foam generators, the following facts should be taken into account:

- a fire can occur both inside and outside an aircraft;

- in aircraft, a mixed fire load is presented, including polymer materials, fuels, rubber products;

- the rate of fire development in the hangar is high due to the likely opening of all hatches and doors;

- Before placing aircraft in aircraft hangars, fuel is usually drained, but part of it still remains in the fuel system. Under the American fire safety standards, an aircraft is considered to be refueled if it contains more than 0.5% of the fuel volume (A1.3.1.1.1 ETL 02-15).

American standards (including ETL 02-15) provide for a cubical method of extinguishing a fire, however, in its wording there are a number of differences from those adopted in Appendix D of SP 5.13130.2009:

- within 1 minute at least 90% of the aircraft projection area must be covered with foam (A1.3.3.2.1 ETL 02-15);

- within 4 minutes the aircraft silhouette area projected on the floor should be covered with foam to a depth of not less than 1 m (A1.3.3.2.2 ETL 02-15);

- installation application time is 15 minutes or 4 immersion times (which is longer) (A1.3.3.4 ETL 02-15);

- the foam breakdown is 1.15 (A1.3.3.3.1 ETL 02-15).

Domestic fire extinguishing standards set forth in Appendix G of SP 5.13130.2009 require a significantly higher flow rate and, accordingly, a higher cost of fire extinguishing installation.

The requirements for the surface method of extinguishing a fire in an aircraft hangar are given in VNTP 11-85 (MGA) and Recommendations on designing of automatic foam fire extinguishing installations in modern hangars. The main provisions of these documents are as follows:

- the estimated area of a fire section is determined by the ratio of the hangar area to the maximum number of aircraft that can fit in it (clause 1.3 of the Recommendations);

- the estimated duration of the fire is 10 minutes (clause 2.9 of the Recommendations);

- the fire extinguishing installation should provide simultaneous and even supply of air-mechanical foam from above to the aircraft and to the floor area of the fire section not covered by it, as well as from below to the lower surfaces of the aircraft (clause 2.1 of the Recommendations);

- it is recommended to apply medium expansion foam from above and low expansion foam from below (clause 2.4 of the Recommendations);

- response time from the moment the detector is triggered until the foam enters the fire bed - no more than 30 seconds (clause 2.11 of the Recommendations);

- fire intensity is taken according to the table:

| Вид ангара | Type of hangar foam concentrate solution feed rate, l/(s · m²) | ||

| To the aircraft from above | To the rest of the hangar area from above | To the aircraft from below | |

| Aircraft Maintenance Base | 0,1 | 0,08 | 0,14 |

| Aircraft Repair Base | 0,14 | 0,1 | 0,16 |

| Note: the estimated area when applying foam from above to the aircraft and from below under the aircraft is determined as the area of the horizontal projection of the aircraft multiplied by a factor of 1.5 | |||

Preliminary calculations for the Boeing 737-800 show the following costs:

| Fire extinguishing method | Regulatory documents | Flow rate, l/s |

| Cubical | ETL 02-15 | 40 |

| Cubical | Appendix G SP 5.13130.2009 (filling to the fuselage top) | 125 |

| Surface for aircraft maintenance bases | VNTP 11-85 (MGA) | 220 |

There is no intensity index for fire robots in normative documents (tables 5.1-5.3 of SP 5.13130.2009 do not apply to robotic fire extinguishing installations according to clause 5.1.4).

Only cubical method of extinguishing fires in the hangar according to Appendix G of SP 5.13130.2009 involves extinguishing inside the fuselage.

Based on the existing regulatory framework, it can be argued that the cubical method of extinguishing fires according to Appendix G of SP 5.13130.2009 is the most economically feasible and legitimate.

Schematic diagram of a high expansion foam fire extinguishing installation for an aircraft hangar

Advantages of a fire extinguishing installation:

- insignificant flow rate;

- the ability to extinguish in confined spaces of the aircraft (fuselage, etc.);

- simplicity of the installation design and maintenance.

Disadvantages of a fire extinguishing installation:

- high expansion foam is effective for class A2 and B fires. Extinguishing textile sheathing materials, metal components of engines, etc. is ineffective;

- the scope of automation of a cubical fire extinguishing installation is higher (according to clause 12.3.4 of SP 5.13130.2009, GOST 12.4.009 and GOST 12.3.046);

- filling with foam the required volume is possible only in closed volumes;

- cubical extinguishing can potentially lead to the death of people who were not evacuated on time.

Schematic diagram of the installation of fire extinguishing with low- and medium expansion foam for an aircraft hangar

Advantages of a fire extinguishing installation:

- effectiveness and safety of extinguishing a fire in a hangar;

- simplicity of design and maintenance of a fire extinguishing installation;

- ease of design and maintenance;

- ability to extinguish all types of aircraft load.

Disadvantages of a fire extinguishing installation:

- high flow rate;

- it is impossible to extinguish a fire in the enclosed spaces of an aircraft (fuselage, etc.).

Firefighting equipment and foam concentrates for extinguishing fire in hangars

The Pozhneftehim produces the following equipment for foam fire extinguishing systems for aircraft hangars:

- foam concentrates;

- foam generators;

- proportioning systems (SKhDP);

- auxiliary equipment;

- modular buildings with proportioning systems and pumping stations (Vityaz BK-PT).

Unfortunately, national standards are not available for many types of foam generators.

The guarantee of product quality for the Customer is the manufacturer‘s accredited test testing stand for equipment and the provision of the following documents:

- license of the Ministry of Emergencies of the Russian Federation for installation, maintenance and repair of fire safety facilities for buildings and structures (for modular buildings);

- SRO certificate of admission to preparation of draft measures to ensure fire safety of capital construction projects, including especially dangerous and technically complex ones (for modular buildings);

- quality system certificate ISO 9001;

- NAKS certificates;

- certificate of conformity issued by an accredited body of EMERCOM of Russia;

- certificate (declaration) for compliance with TR TS 032/2013 for the bladder tank;

- safety justification (OB) specified in clause 45 of the TR TS 032/2013 for the bladder tank;

- certificate of compliance with the requirements of GOST 30546.1-98, GOST 30546.2-98, GOST 30546.2-98 (earthquake resistance 9 points on the MSK-64 scale) for a bladder tank (if necessary);

- justifying calculation of the corrosion rate of the bladder tanks inner surface made by an accredited organization (for bladder tanks);

- manufacturer written confirmation for the Customer representative production inspection to take part in acceptance tests.

Fire extinguishing systems design

The Pozhneftehim interaction with customer companies and design organizations in the development of fire protection Concepts, Special technical conditions (STU), and Fire safety measures (MOPB) is presented in the diagram.

The Pozhneftehim has extensive experience in the development of integrated foam fire extinguishing installations for hangars of various purposes and levels of responsibility. If you work in the field of industrial fire safety and you have questions about the design of aircraft hangar buildings, the installation of a fire extinguishing system in aircraft hangars, the choice of fire equipment and foam concentrate, please contact our specialists for advice.

Отзывы наших клиентов

Contact information to order Pozhneftehim complex supplies

Questions concerning the choice of foam concentrates for fire extinguishing

Tatyana Potapenko, foam project manager +7 (499) 703 01 32, ext.172

Questions concerning the choice of firefighting equipment

Sergey Vypritsky, Project Manager +7 (499) 703 01 32, ext.153

Questions on documentation regarding Fire safety measures (MOPB) and Special technical conditions (STU)

Sergey Titenkov, Head of Regulatory and Technical Department +7 (499) 703 01 32, ext.159

Antifire bladder tank (BD)

Antifire bladder tank (BD)  Fire stabilizer (PUS)

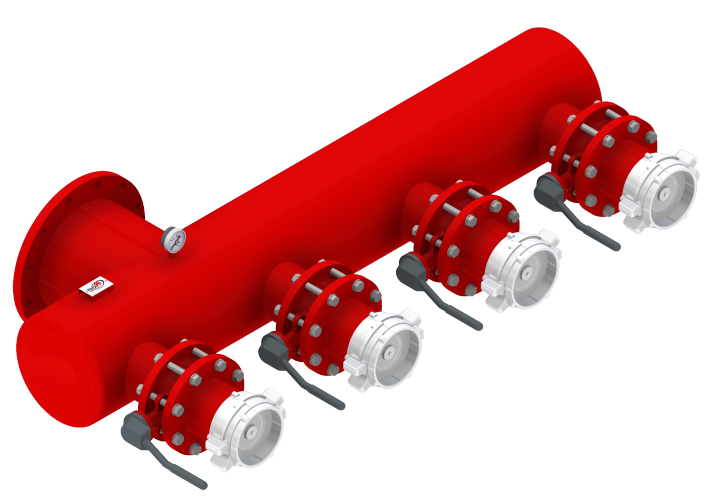

Fire stabilizer (PUS) Fire hydrant manifolds (UPT)

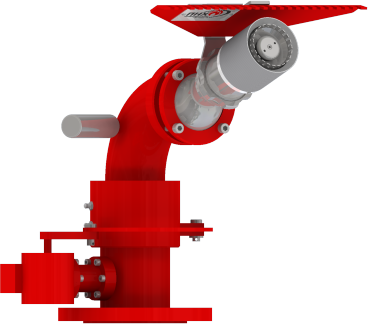

Fire hydrant manifolds (UPT)  Turbopen universal foam generator (UGP)

Turbopen universal foam generator (UGP) Antifire Universal foam/water nozzle (UVPN)

Antifire Universal foam/water nozzle (UVPN)