Deluge sprinkler, Antifire universal water-foam spray nozzle (UVPN)

Sertificate ТР ЕАЭС 043/2017 ЕАЭС RU С-RU.ЧС13.В.00456/22

GOST СТ Р 51043-2002, TU 4854-011-72410778-07 (red. 4)

General

Purpose and scope

Antifire universal water-foam spray nozzle (UVPN) certified for compliance with GOST R 51043-2002 “Automatic water and foam fire extinguishing installations. Sprinklers. General technical requirements. Test methods”, is a deluge sprinkler and a device for producing continuous or sprayed jets of water or low expansion foam with a normalized index of uniformity of discharge in a wide pressure range.

The Antifire UVPN is used to eliminate fires with surface or volume-surface methods. The volume-surface method is realized if the entire protected space is in the area covered by the torches of extinguishing agent created by the water-foam nozzles.

The Antifire UVPN creates increased resistance to heat fluxes and wind loads during the application of water jets or low-expansion foam due to the high rate of expiration of the extinguishing agent.

The Antifire I (II) UVPN are manufactured with three types of connections:

- with flanges or, on request, on GM type fire connection heads;

- with a rotary device of the PU-A type;

- with a rotary device of the PU-B type.

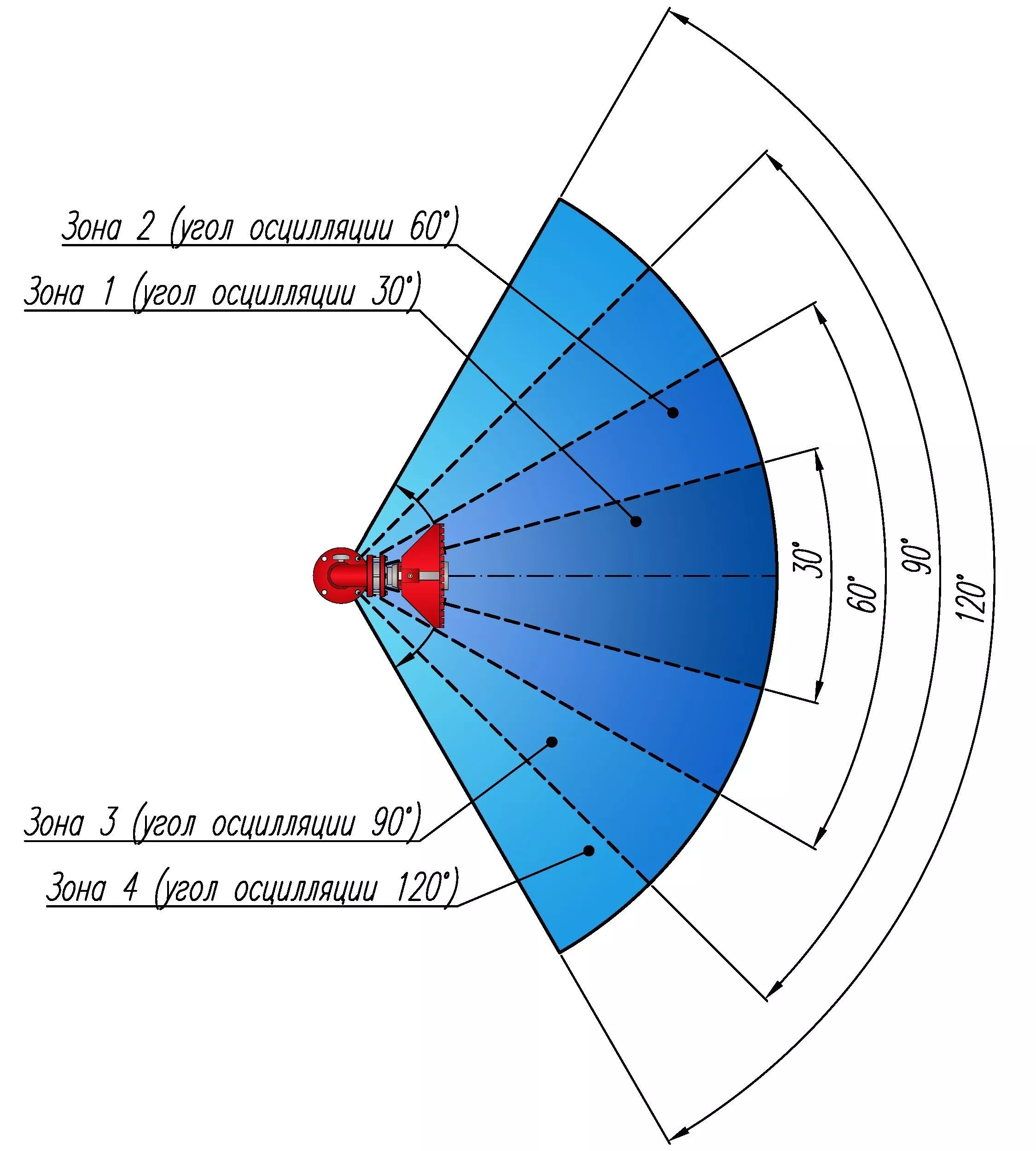

- with an oscillator, a device that enables, due to the takeoff of the water flow energy, to turn the nozzles left/right into sectors with an angle of 30°, 60°, 90°, 120° (optional).

The Antifire deluge sprinklers in foam fire extinguishing installations are designed to operate with film-forming foam concentrates such as AFFF, AFFF/AR, AFFF/AR-LV, as well as S/AR according to GOST R 50588. We recommend using the Aquafom NSV foam concentrates to produce low-, medium- and high-expansion foam.

As the Antifire UVPN does not contain combustible and fusible materials (except for sealing cuffs on the oscillator rotary device), it maintains operability when exposed to heat up to 800 °C during the inertia time necessary for applying fire extinguishing agents to the combustion zone with foam fire extinguishing and water cooling installations.

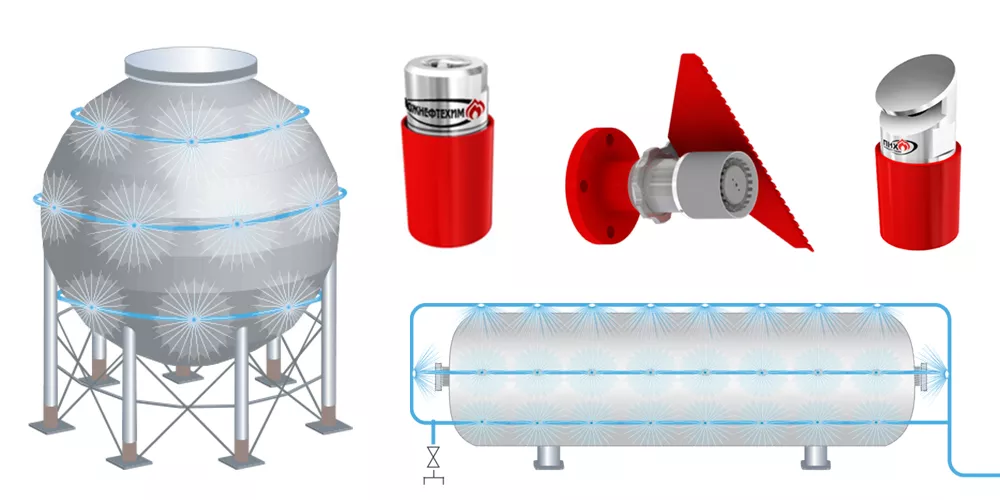

Scope of application

Antifire-I is a special universal deluge sprayer designed for fire protection of various objects (production buildings, workshops where the use of sprinklers or general-purpose drenchers is not practical; technological sites, whatnots associated with the use of flammable and combustible liquids; technological sites of berthing complexes, helipads, aircraft hangars and much more). Antifire-I can be used not only for fire extinguishing, but also for water cooling of various objects (horizontal storage tanks for LPG under pressure, isothermal tanks, etc.). The possibility of their installation not on the ceiling, but along the walls, makes the use of the UVFN Antifire more efficient and convenient.

Antifire-II is a special purpose universal deluge sprinkler, which is recommended for fire protection of railway and road fill racks, tank trucks with flammable and combustible liquids, various technological tanks, etc., when it is necessary to direct a part of the jet directly to the neck, hatch, location of the most dangerous site, equipment, etc. In addition, this modification of the sprinkler is recommended if there is a need for a greater range when applying a torch-like jet.

Distinctive advantages

Antifire universal water foam nozzles are available in two versions:

- Antifire-I provides a continuous or sprayed jet of water (low-expansion foam) with a uniform distribution of liquid or foam along the cone of the torch with a spray angle of up to 120º;

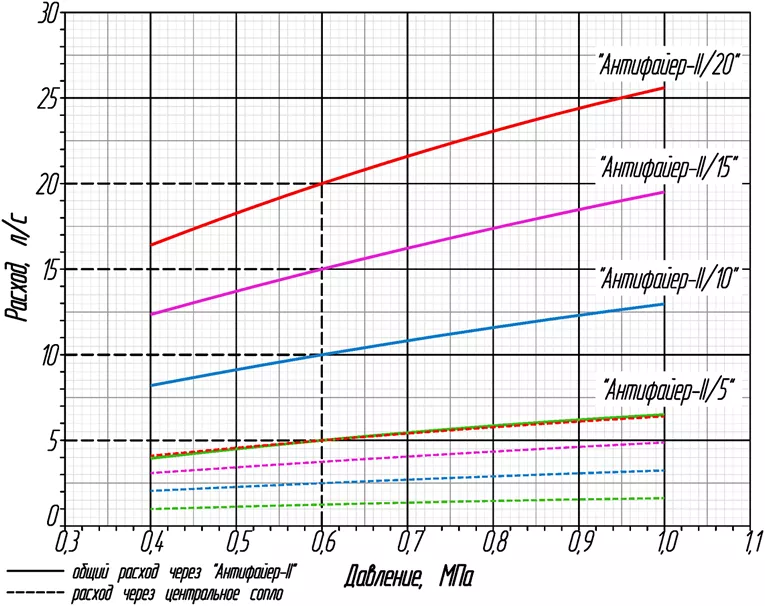

- Antifire-II provides a continuous or sprayed jet of water (low-expansion foam) in the form of a filled cone with an angle of up to 120º, in which part of extinguishing agents is applied through an integrated low-expansion foam generator, where a central continuous stream of water or low-expansion foam is formed.

The universal Antifire water-foam jet nozzle is equipped on request with a control valve, which enables providing high-quality water or foam jets with a pressure upstream of the nozzle below the nominal value, as well as avoiding an exceeding nominal pressure upstream of the nozzle due to increased flow rate (self-regulation function - SR).

- normalized discharge uniformity

- resistance to temperature influences;

- availability of an integrated fine filter.

- automatic flow control depending on the power of the extinguishing agent supply source with the formation of sprayed water jets or low-expansion high quality foam (if there is a self-regulation function);

- the possibility of using an oscillator;

- the possibility of applying for fire protection of railway and truck loading racks and other objects due to the formation of a separate jet in the central part of the torch, directed to the zone of the neck of the tanks for transportation of flammable and combustible liquids.

Versions

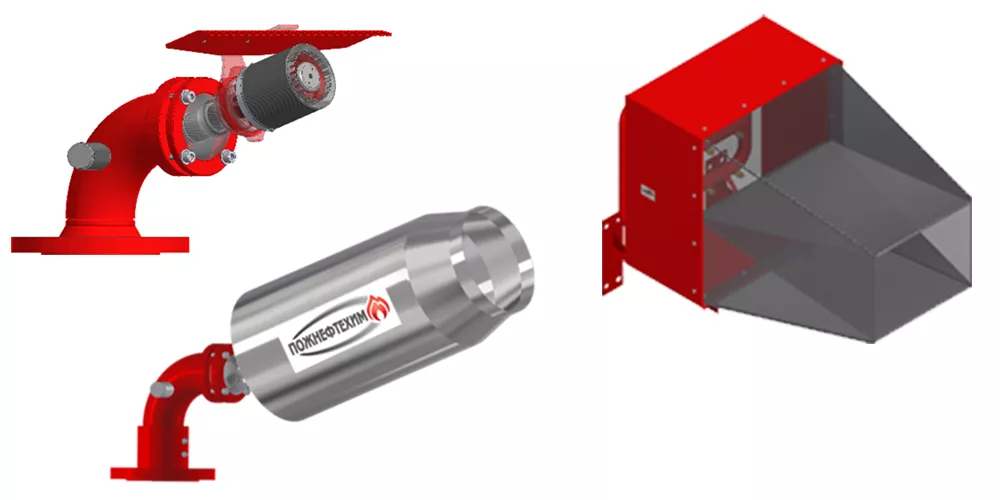

Antifire-I with flanges

Antifire-II with flanges

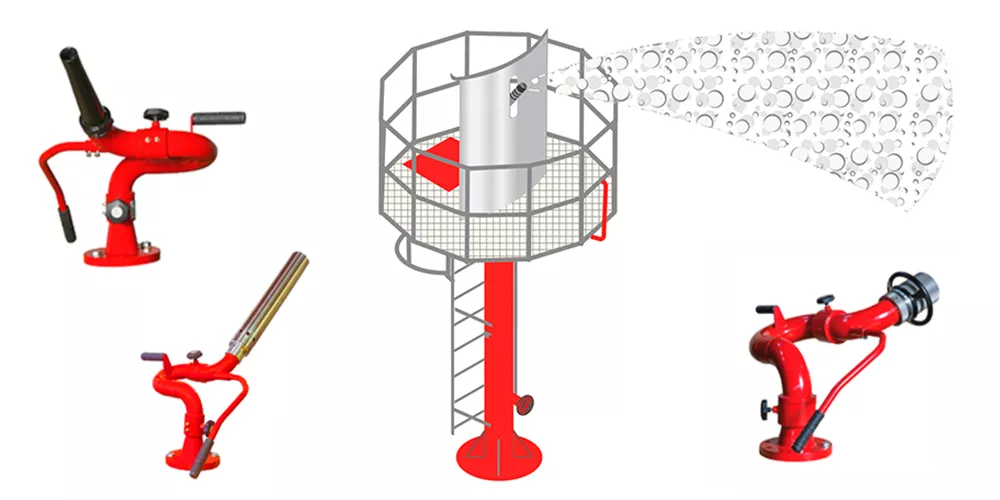

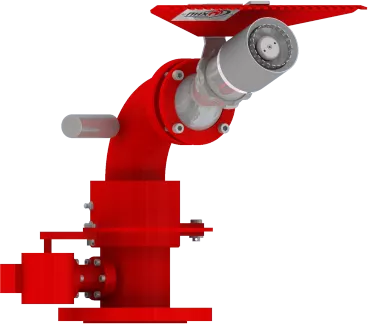

Antifire-I(II) with a rotary device PU-А

Antifire-I(II) with a rotary device PU-B

Antifire-I(II) with a rotary device PU-B with oscillator

Universal Antifire water-foam nozzles are available in two versions:

- «Antifire-I provides a continuous or sprayed jet of water (low-expansion foam) with a uniform distribution of liquid or foam along the cone of the torch with a spray angle of up to 120º;

- Antifire-II provides a continuous or sprayed jet of water (low-expansion foam) in the form of a filled cone with an angle of up to 120º, in which part of the extinguishing agents is applied through an integrated low-expansion foam generator, where a central continuous stream of water or low-pressure foam is formed.

The universal antifire water-foam jet nozzle is equipped on request with a control valve, which enables providing high-quality water or foam jets with a pressure upstream of the nozzle below the nominal value, as well as avoiding an exceeding nominal pressure upstream of the nozzle due to increased flow rate (the self-regulation function is abbreviated as SR).

Specifications

Materials of manufacture

In terms of resistance to climatic conditions, the Antifire UVPN is rated to the versions U, HL, UHL, T, OM according to GOST 15150-69. The range of ambient temperature is from minus 60 ºС to plus 50 ºС.

The manufacturing material for the water-foam nozzle Antifire UVPN in these climatic modifications, as well as those for operation on salt water, is stainless steel.

Key Specifications

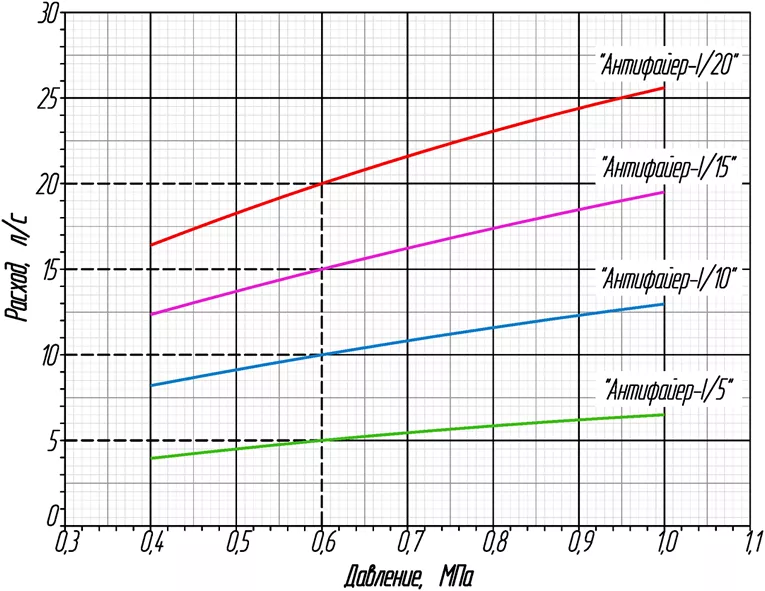

| Номинальное давление, МПа1 |

| Диапазон рабочих давлений, МПа 0,4–1,0 |

| Расход при номинальном давлении, л/с, не менее 5 |

| Кратность пены, не менее2 4–8 |

Масса, кг, не более |

10 |

12 |

20 |

| Срок службы, лет, не менее 10 |

| Rated pressure, MPa1 |

| Диапазон рабочих давлений, МПа 0,4–1,0 |

| Расход при номинальном давлении, л/с, не менее 10 |

| Кратность пены, не менее2 4–8 |

Масса, кг, не более |

10 |

12 |

20 |

| Срок службы, лет, не менее 10 |

| Номинальное давление, МПа1 |

| Диапазон рабочих давлений, МПа 0,4–1,0 |

| Расход при номинальном давлении, л/с, не менее 15 |

| Кратность пены, не менее2 4–8 |

Масса, кг, не более |

12 |

15 |

25 |

| Срок службы, лет, не менее 10 |

| Indicator name | Indicator value | |||

| Antifire-I(II)/5 | Antifire-I(II)/10 | Antifire-I(II)/15 | Antifire-I(II)/20 | |

| Rated pressure, MPa (*) (****) | 0,6 | |||

| Operating pressure range, MPa (****) | 0,4–1,0 | |||

| Flow, l/s, at rated pressure, min | 5 | 10 | 15 | 20 |

| Performance coefficient K, min | 0,63 | 1,27 | 1,93 | 2,55 |

| Foam expansion, min (**) | 5–8 | |||

| Discharge uniformity index according to GOST R 51043-2002 (Discharge uniformity coefficient R) (***) | max 0,5 | |||

| Operability at thermal influence, min, °C | 800 | |||

| Weight, kg, max | ||||

| 10 | 10 | 12 | 12 |

| 12 | 12 | 15 | 15 |

| 20 | 20 | 25 | 25 |

| Service life, years, min | 10 | |||

Notes:

- (*) Antifire universal water foam nozzles can be made upon request for a nominal pressure of 0,4, 0,5, 0,7, 0,8, 0,9, 1,0 MPa.

- (**) The expansion is indicated when using a film-forming foam concentrate of the NSV type. It is allowed to use film-forming foam concentrates that provide low-expansion foam of at least 15 according to GOST R 50588.

- (***) The discharge uniformity index according to GOST R 51043-2002 is set for type I UVPN.

- (****) In the manufacture of UVPN equipped with an oscillating device, it is necessary to take into account the pressure loss of 0.1 MPa, that is, the pressure upstream of UVPN must be taken by 0.1 MPa more.

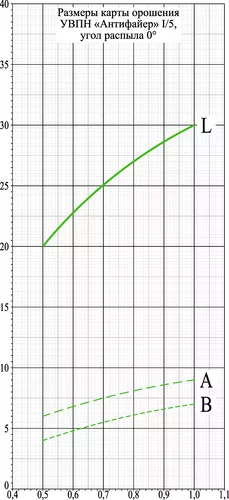

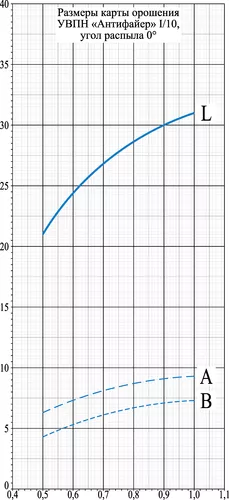

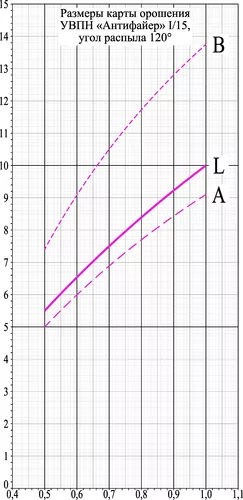

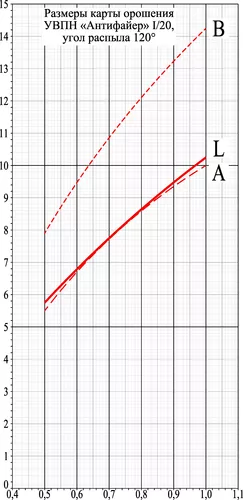

Flow and pressure graph

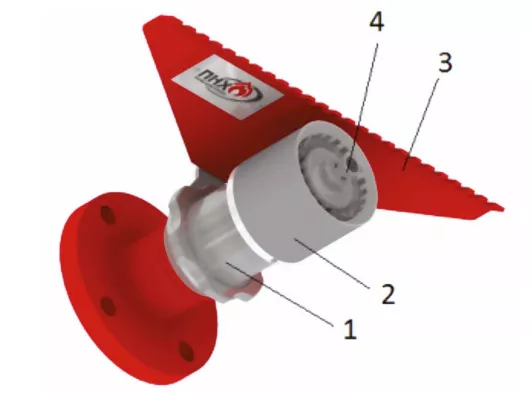

Key elements

1 – housing;

2 – torch angle adjuster (*);

3 – discharge map regulator (manifold) (*), (**);

4 – central nozzle (for modification II);

- automatic integrated control valve (optional);

- integrated cylindrical fine filter (installed in a ball bearing on PU-A and PU-B).

Notes:

(*) – after assembly, commissioning, setting the supply angles of the fire suppressant at the factory, the locking-adjusting elements are locked and sealed.

(**) based on technical estimate and/or on request, it is allowed to manufacture fire-extinguishing systems (installations) connected to fire pipelines through flanges in accordance with GOST 33259-2015 using gaskets made of non-combustible material.

Operating principle

The torch regulator (item 2) has five key positions:

- position 0º provides the formation of a compact jet of extinguishing agent;

- position 30°, 60°, 90°, 120° ensures the formation of a torch jet with a spray angle of 30°, 60°, 90°, 120°, respectively.

The discharge map regulator (manifold) can be used when applying a torch jet with an angle of 60° or more. It is intended to adjust the discharge map generated by the water-foam nozzle, or to prevent application of extinguishing agents outside the protected zone by changing the flow direction of the upper, lower or side parts of the stream.

When the manifold is installed on top of the housing in the extended position, part of the flow of the extinguishing agent loses its flow rate and is redistributed to the zone located closer to the place of installation of the water-foam nozzle. Depending on the torch angle and the inclination angle relative to the horizontal plane, the discharge map changes. At the same time, the range (length) of the discharge map is partially reduced, the width and area of the discharge in the immediate vicinity of the installation increases.

When the manifold is installed in a lateral or lower position, discharge maps of various geometric sizes are formed.

When the extinguishing agent is supplied to the water-foam nozzle and the calculated pressure at the inlet is created, the extinguishing agent passes through the housing (item 1), gets cleaned in a fine filter and then enters the distributor consisting of a torch angle regulator (position 2) and a control valve (if available). Upon exiting the nozzle, a continuous or sprayed jet of water or low-expansion foam is formed (when the foam concentrate is applied). Depending on the preset positions of the torch and manifold regulator, the required discharge (irrigation) map is formed.

Types of Mounting Flanges

Тип УВПН «Антифайер», для которого может быть использовано поворотное устройство «Антифайер»-I(II)/5 «Антифайер»-I(II)/15 |

Назначение поворотного устройства Без регулировки положения УВНП «Антифайер» по вертикали или по горизонтали |

Для присоединения к трубопроводу установки пожаротушения или водяного охлаждения 1-32-16

50-16-01-1 80-16-01-1 |

Для присоединения к УВПН «Антифайер» – |

Тип УВПН «Антифайер», для которого может быть использовано поворотное устройство «Антифайер»-I(II)/5 «Антифайер»-I(II)/15 |

Назначение поворотного устройства Регулировка положения УВПН «Антифайер» в любом направлении полусферы на угол не менее 30º от центральной оси |

Для присоединения к трубопроводу установки пожаротушения или водяного охлаждения 50-16-01-1 100-16-01-1 |

Для присоединения к УВПН «Антифайер» Шаровое соединение |

The Antifire UVPN type for which the rotary device can be used Antifire-I(II)/5 Antifire-I(II)/15 |

Purpose of the rotary device Регулировка положения УВПН «Антифайер» вокруг оси фланца растворопровода на 360º и в любом направлении полусферы на угол не менее 30º от центральной оси |

Для присоединения к трубопроводу установки пожаротушения или водяного охлаждения 80-16-01-1 100-16-01-1 |

Для присоединения к УВПН «Антифайер» Шаровое соединение |

Type of connection to the raster

| The Antifire UVPN type for which the rotary device can be used | Purpose of the rotary device | Тип присоединительных фланцев | |

| For connection to a fire extinguishing or water cooling installation | For connection to UVPN | ||

| Antifire-I(II)/5 Antifire-I(II)/10 Antifire-I(II)/15 Antifire-I(II)/20 |

No UVPN position adjustment Antifire vertically or horizontally |

According to GOST 33259-2015: 32-16-01; 32-16-11 50-16-01; 50-16-11 80-16-01; 80-16-11 (by order) According to GOST 33259-2015: 80-16-01; 80-16-11 100-16-01; 100-16-11 (by order) |

– |

| Antifire-I(II)/5 Antifire-I(II)/10 Antifire-I(II)/15 Antifire-I(II)/20 |

Регулировка положения УВПН «Антифайер» в любом направлении полусферы на угол не менее 30º от центральной оси |

Согласно ГОСТ 33259-2015: 50-16-01; 50-16-11 80-16-01; 80-16-11 Согласно ГОСТ 33259-2015: 100-16-01; 100-16-11 80-16-01; 80-16-11 (по заказу) |

Шаровое соединение |

| «Антифайер»-I(II)/5 «Антифайер»-I(II)/10 «Антифайер»-I(II)/15 «Антифайер»-I(II)/20 |

Регулировка положения УВПН «Антифайер» вокруг оси фланца растворопровода на 360º и в любом направлении полусферы на угол не менее 30º от центральной оси |

Согласно ГОСТ 33259-2015: 80-16-01; 80-16-11 Согласно ГОСТ 33259-2015: 100-16-01; 100-16-11 80-16-01; 80-16-11 (по заказу) |

Шаровое соединение |

Layout and technical conditions for the use of the Antifire UVFN - universal special deluge sprinkler with an oscillator

Oscillator Specifications:

- when using an oscillator, it is necessary to take into account the pressure drop of 0.1 MPa, that is, the pressure upstream of the must be taken by 0.1 MPa higher;

- in the marking of the Antifire UVPN it is necessary to indicate the value of the oscillation position (1, 2, 3 or 4 - according to the left drawing);

- when developing discharge maps using an oscillator, the extreme edges of zones 1, 2, 3, 4 should be taken as the axis of the discharge maps shown in paragraph Discharge maps.

Для просмотра полного описания технических характеристик отправьте заявку или войдите под своим профилем

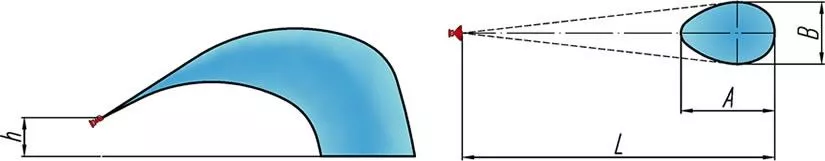

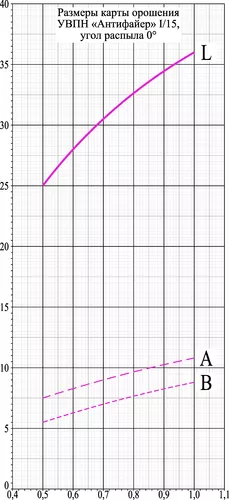

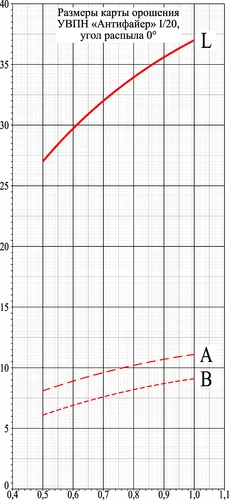

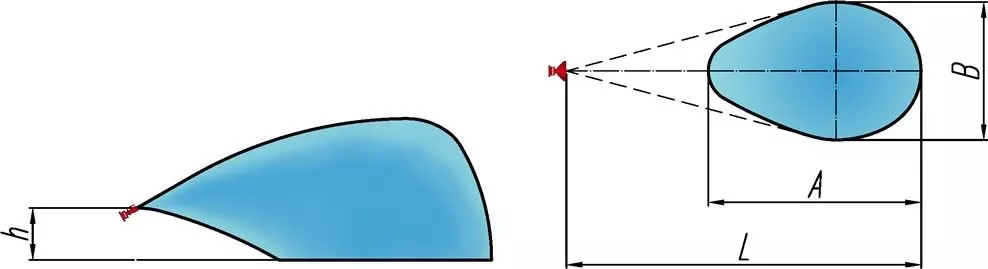

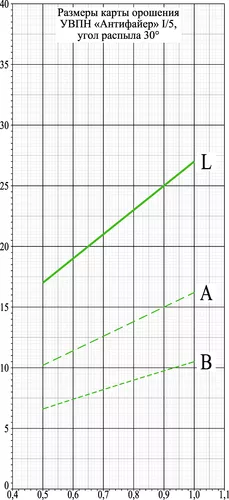

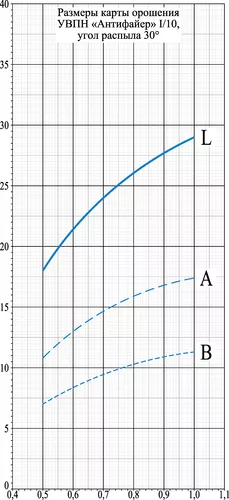

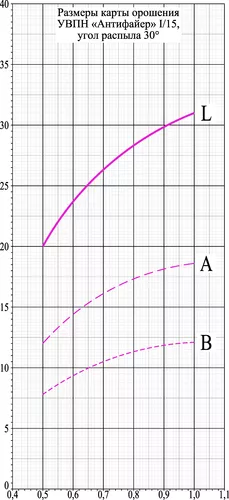

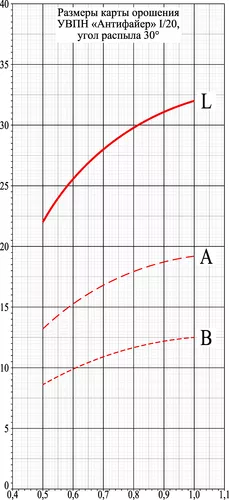

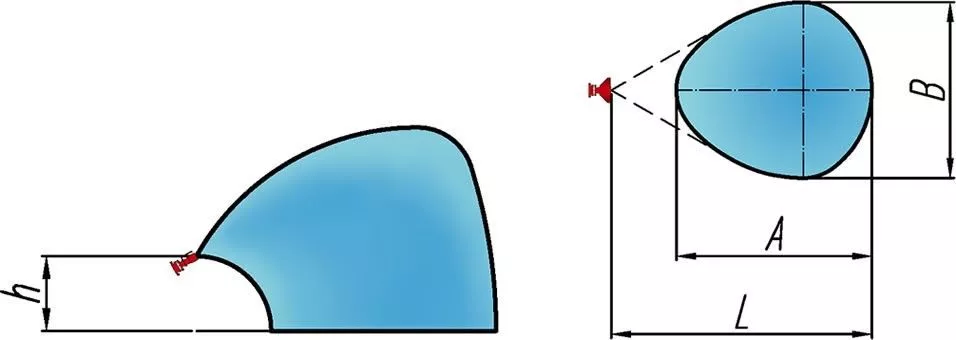

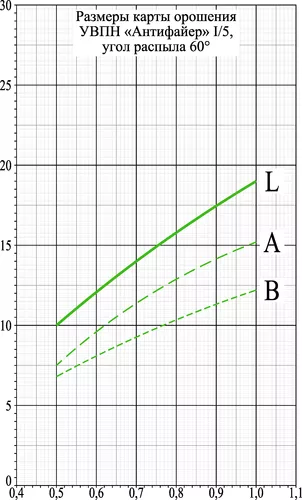

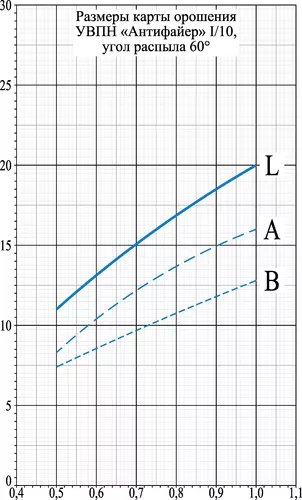

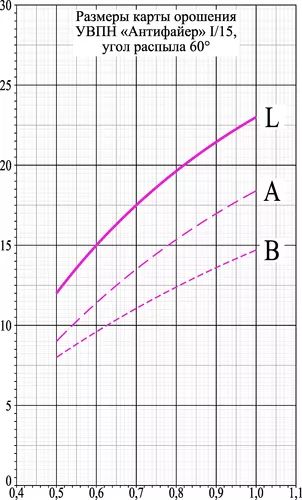

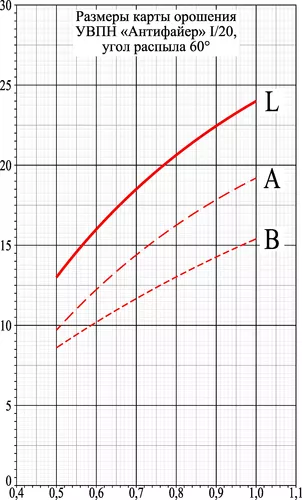

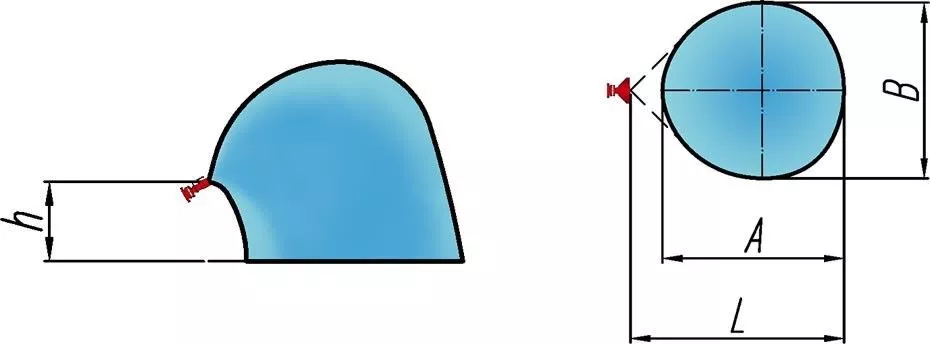

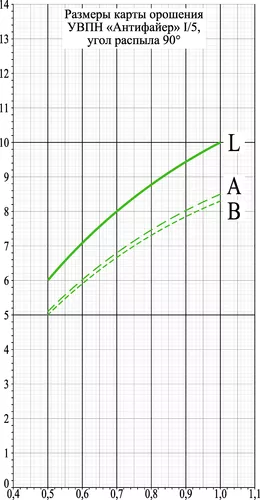

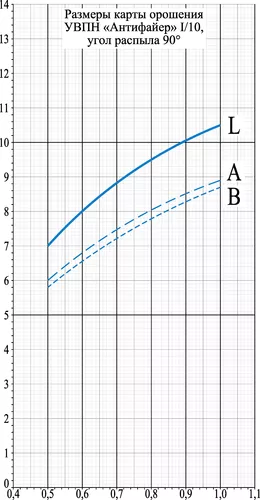

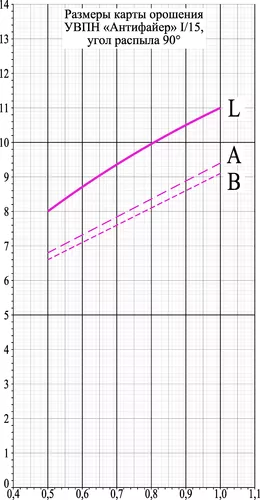

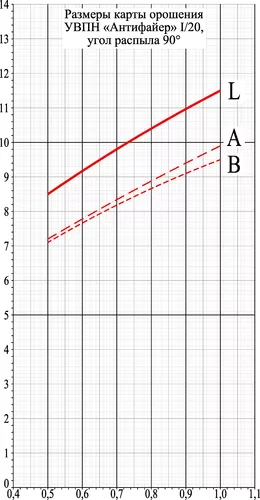

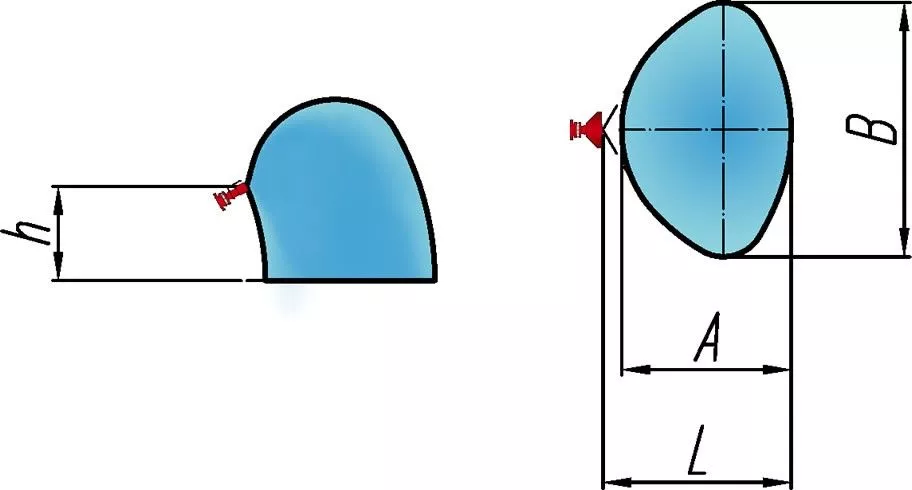

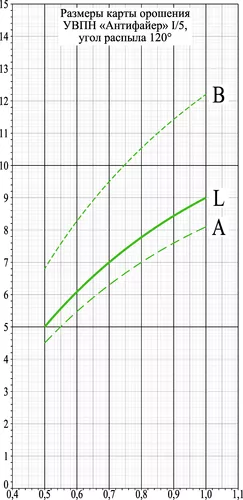

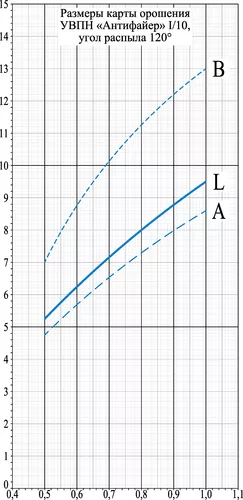

Discharge maps

Discharge maps are given when installing the Antifire UVPN at an angle of 30º upwards relative to the horizon. The installation height is 2.5-3 m. If the installation height is higher than the indicated values of the discharge map, it is allowed to accept similar maps. A slight increase in discharge maps can be compensated for by a decrease in the angle of inclination relative to the horizon during commissioning or design solutions.

Design Information

Antifires UVPN are universal special deluge sprinklers provided for equipping fire extinguishing systems and water cooling, taking into account the provision of standard fire extinguishing intensities (water cooling) and design features of protected areas. Installation of water-foam nozzles on the pipelines of fire extinguishing and water cooling systems is carried out with a preliminary installation of the torch angle and the position of the discharge map controller.

When designing the discharge maps (see above), they should be adopted in the following order:- depending on the design and space-planning decisions of the protected zone, determine the height of the nozzle, the angle of inclination and the most appropriate angle of the jet;

- в зависимости от конструктивных и объёмно-планировочных решений защищаемой зоны определить высоту установки насадка, угол наклона и наиболее целесообразный угол факела струи;

- depending on the selected head, flow rate, spray angle and installation location of the nozzle, determine discharge maps and apply them to the plan of the protected zone. If it is necessary to shorten the range, reduce the angle of inclination to the surface to be protected (it is recommended to consult with specialists of the Pozhneftehim Group);

- if it is necessary to maximize the coverage of the protected area, provide equipment of the Antifire UVPN with oscillators;

- determine the optimal placement of the Antifire UVPN taking into account the received discharge maps.

Notes

- It is not always necessary to ensure coverage of the protected area with discharge maps. Mind that low-expansion foam can spread over the surface of a burning oil or oil product.

- To protect the Antifire universal special deluge sprinklers from ingress of foreign mechanical impurities and impairing its operability at the inlet, it is necessary to install the Tauer universal fire filter (PFU) TU 4854-012-72410778-07 with a cell size of 2x2 mm.