FIRE MONITOR ANTIFIRE, FIXED (LS)

GOST R 51115-97, TU 4854-026-72410778-2013

General

Purpose and scope

The Antifire fixed fire monitors are intended for use as a part of foam/water fire extinguishing installations, water cooling, when fire extinguishing agents are applied over long distances or at high-rise objects, as well as when there is a need to carry out fire extinguishing at safe distances.

Reliable and stable operation of fire monitors is ensured at an ambient temperature of minus 60 °C to plus 50 °C.

Distinctive advantages

- the design is convenient to operate when placing fire monitors on fire towers of PVU type (control elements do not prevent the operator’s work on the tower platform; the control of the horizontal and vertical nozzle positions, the adjustable cone angle and flow rate, as well as the water curtain is ensured etc.);

- extended package of the basic design, depending on the application and tasks;

- optional delivery complete with fire towers of PVU type;

- material stainless steel.

Scope of supply

The basic package of Antifire fixed fire monitors contains:

- a turnable base to provide nozzle rotation around the axis of the mounting flange, as well as change the angle in the vertical plane;

- a nozzle for applying a continuous water jet (for LS-S);

- a nozzle for applying a continuous low expansion foam jet (for LS-SP);

- universal water/foam nozzle for applying a continuous or sprayed jet of water or low-expansion foam with adjustable fog cone.

Optionally, the Antifire fixed fire monitors can be equipped with:

- a pressure gauge for monitoring nozzle pressure;

- a positional flow-rate regulator with a cleaning function (this equipment is provided only for universal nozzles of the LS-SU type);

- an ejector to intake a foam concentrate from an external container (this equipment is provided only for LS-SP and LS-SU types);

- a deflector for narrowing and spraying a continuous fog cone (this equipment is provided only for nozzles of the LS-S type);

- sprinkler to form a water curtain;

- an oscillator for reversing the nozzle left / right rotation when applying water or foam concentrate solution;

- overlapping disk lock at the nozzle inlet.

Note

It is recommended to protect the fire monitor with Tauer universal fire filters (PFU) with a mesh size of 2x2 mm. The LS-SU fire monitors which are not equipped with a positional flow-rate regulator with a cleaning function, must be protected with fire filters.

Models

Fire monitor Antifire LS-S

Fire monitor Antifire LS-SP

Fire monitor Antifire LS-SU

By functionality and specifications, the Antifire fixed fire monitors are divided in accordance with GOST R 51115-97 into:

- LS-S - fixed fire monitors designed to form a continuous water jet;

- LS-SP - fixed fire monitors designed to form a continuous foam jet;

- LS-SU - fixed universal fire monitors to form a continuous and atomized jet of water or low-expansion foam with a variable cone angle (equipped with a universal water/foam nozzle);

Depending on the nominal flow rate, the Antifire fire monitors are divided into:

- fixed fire monitors with a nominal flow rate of 20 l/s to 40 l/s

- fixed fire monitors with a nominal flow rate of 40 l/s to 60 l/s;

- fixed fire monitors with a nominal flow rate of 60 l/s to 100 l/s.

Specifications

Materials of manufacture

Turnable housing of stainless steel.

Nozzles for a continuous water jet (for LS-S type) - aluminum alloy in accordance with GOST 1583.

Nozzles for a continuous foam jet (for LS-SP type): nozzle - brass, case - stainless steel.

Universal nozzle (for LS-U type) - stainless steel.

Key Specifications

Номинальный расход, л/с от 20 (включительно) до 40 |

Диапазон рабочих давлений, МПа 0,4–1,0 |

Расход воды, л/с, не менее**** 20 |

Расход водного раствора пенообразователя, л/с, не менее**** 20 |

Дальность струи (по крайним каплям), м, не менее*** |

50 |

35 |

30 |

30 |

Кратность пены, не менее**** 5 |

Диапазон изменения угла факела распылённой струи* 0°–120° |

Перемещение ствола в горизонтальной плоскости, не менее** ± 180° |

Перемещение ствола в вертикальной плоскости, не мене |

75° |

8° |

Климатическое исполнение У, ХЛ, УХЛ, Т, ОМ |

Номинальный расход, л/с от 40 (включительно) до 60 |

Диапазон рабочих давлений, МПа 0,4–1,0 |

Расход воды, л/с, не менее**** 40 |

Расход водного раствора пенообразователя, л/с, не менее**** 40 |

Дальность струи (по крайним каплям), м, не менее*** |

60 |

40 |

35 |

35 |

Кратность пены, не менее**** 5 |

Диапазон изменения угла факела распылённой струи* 0°–120° |

Перемещение ствола в горизонтальной плоскости, не менее** ± 180° |

Перемещение ствола в вертикальной плоскости, не мене |

75° |

8° |

Климатическое исполнение У, ХЛ, УХЛ, Т, ОМ |

Номинальный расход, л/с от 60 (включительно) до 100 |

Диапазон рабочих давлений, МПа 0,4–1,0 |

Расход воды, л/с, не менее**** 40 |

Расход водного раствора пенообразователя, л/с, не менее**** 60 |

Дальность струи (по крайним каплям), м, не менее*** |

70 |

45 |

40 |

40 |

Кратность пены, не менее**** 5 |

Диапазон изменения угла факела распылённой струи* 0°–120° |

Перемещение ствола в горизонтальной плоскости, не менее** ± 180° |

Перемещение ствола в вертикальной плоскости, не менее |

75° |

8° |

Климатическое исполнение У, ХЛ, УХЛ, Т, ОМ |

| Indicator name | Indicator value | ||

| LS20 | LS40 | LS60 | |

| Nominal flow rate, l/s | 20 (inclu- sive) to 40 | 40 (inclu- sive) to 60 | 60 (inclu- sive) to 100 |

| Range of Operating pressures, MPa | 0,4–1,0 | ||

| Water flow rate, l/s, min**** | 20 | 40 | 60 |

| Water solution of foam concentrate, l/s, min**** | 20 | 40 | 60 |

| Range of a jet (extreme drops), m, min*** | |||

| • continuous water jet | 50 | 60 | 70 |

| • continuous foam jet | 35 | 40 | 45 |

| • foamy flat jet (with deflector closed and fog cone not less than 30°)* | 30 | 35 | 40 |

| • spray water jet (with fog cone 30°) | 30 | 35 | 40 |

| Foam expansion, min**** | 5 | ||

| Range of fog cone* | 0°–120° | ||

| Nozzle horizontal turning angle, min** | ± 180° | ||

| Nozzle vertical moving angle, min | |||

| • upward | 75° | ||

| • downward | 8° | ||

| Climatic models | U, HL, UHL, T, OM | ||

* For universal nozzles.

** The turning angles of the fire monitors can be limited by their structural elements, as well as the design of a fire truck, watercraft, trailer, etc., which should be reflected in regulatory documents.

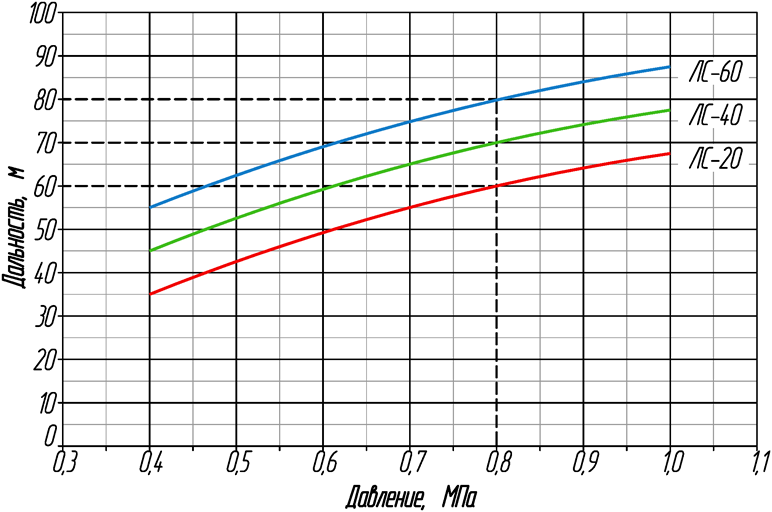

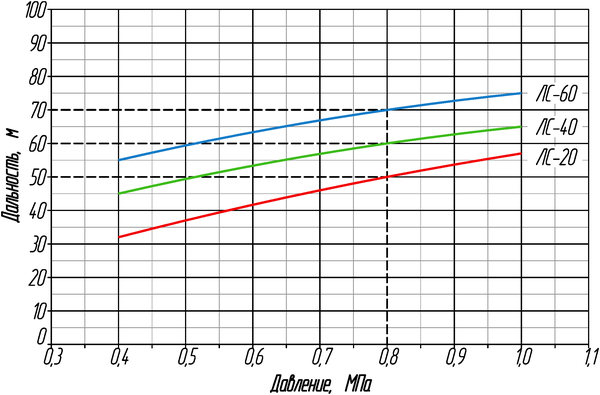

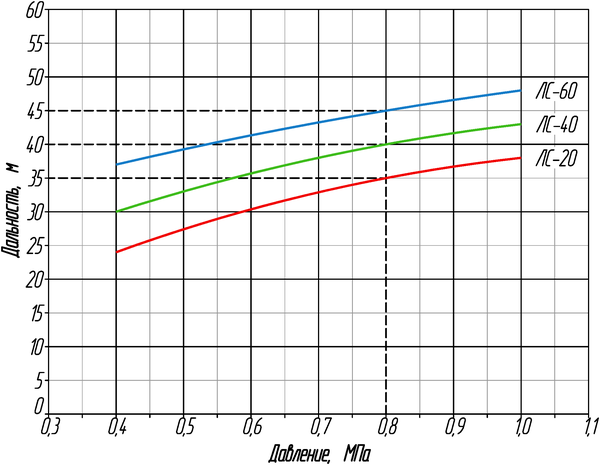

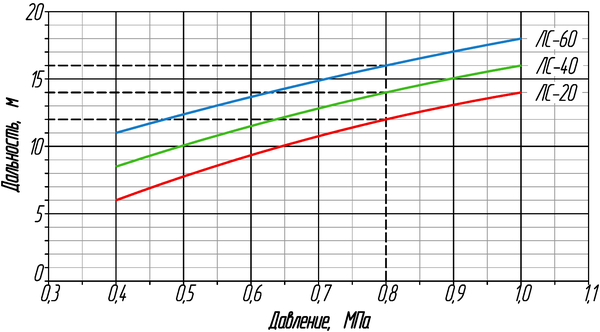

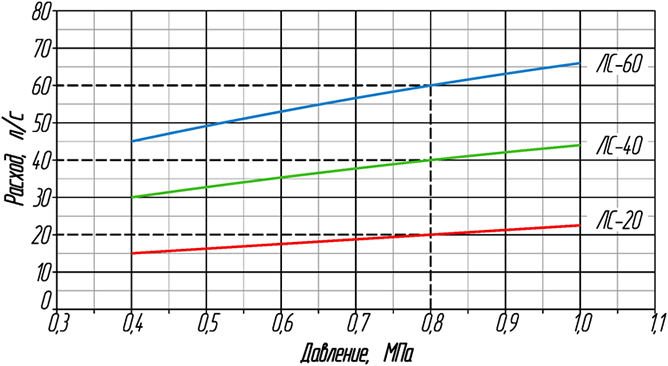

*** Jet ranges are given for monitors in the working position at an angle of inclination to the horizon of 30°, at a pressure of 0.8 MPa.

**** Values at 0.8 MPa.

Range and pressure graphs

To compare two graphs, select both values.

Flow and pressure graphs for LS-S, LS-SP, LS-SU

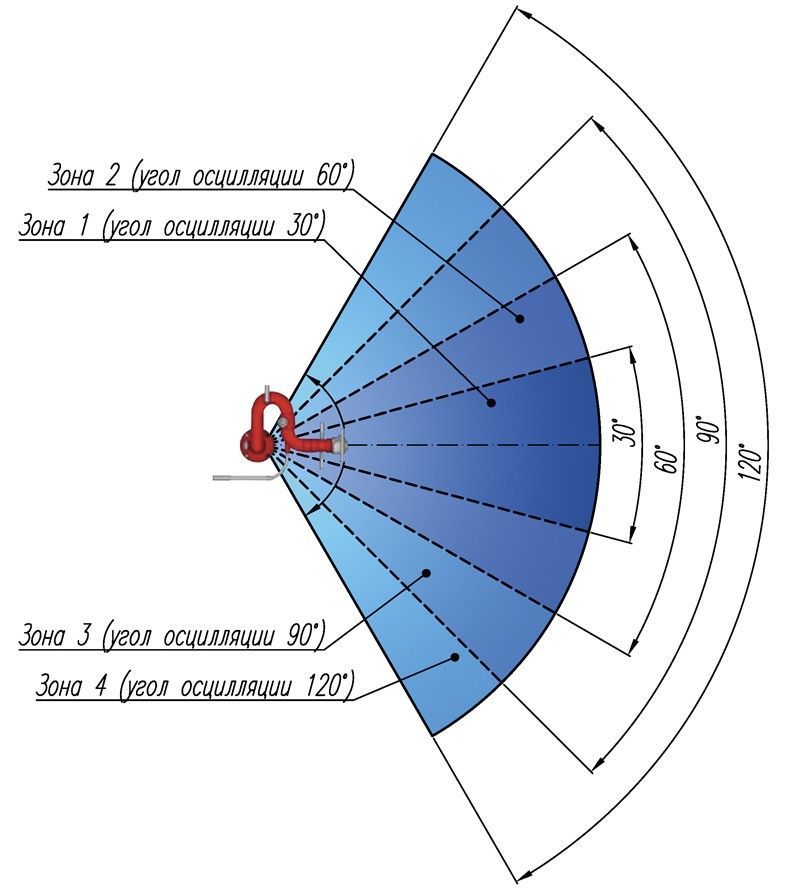

Scheme and technical conditions for the use of an oscillator equipped the Antifire LS fire monitor

Specifications for oscillator application:

- when using an oscillator, it is necessary to take into account the pressure loss of 0.1 MPa, i.e., the LS upstream pressure must be increased by 0.1 MPa;

- in the LS labeling, it is necessary to indicate the value of the oscillation position (1, 2, 3 or 4).

Для просмотра полного описания технических характеристик отправьте заявку или войдите под своим профилем

Design Information

When determining the number of fire monitors and developing sprinkler irrigation maps with a radius of monitor’s action, the range values indicated on the graphs should be taken with a factor 0.7. Multiplying the value of the LS range obtained from the graphs by a decreasing factor, determine the effective range. This is necessary when taking into account wind loads and ensuring the application of the bulk of the extinguishing agent to the protected object. This factor also takes into account that, according to the methodology of GOST R 51115, LS ranges are determined by the extreme drops with a fair wind up to 2 m/s.

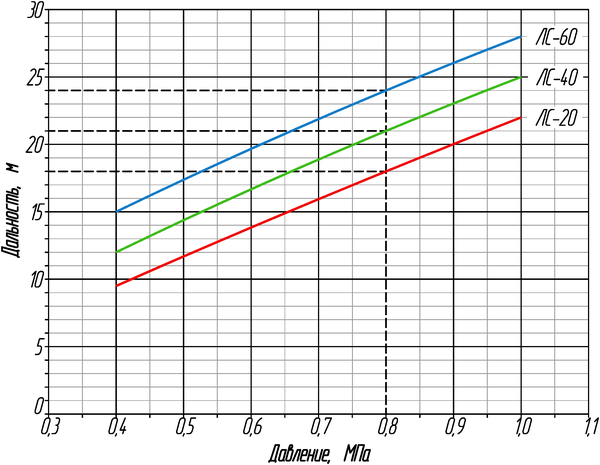

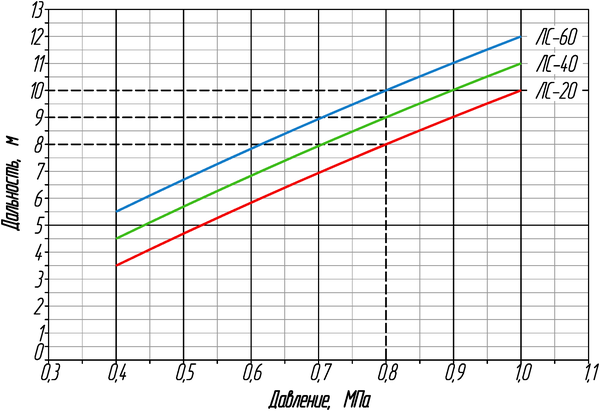

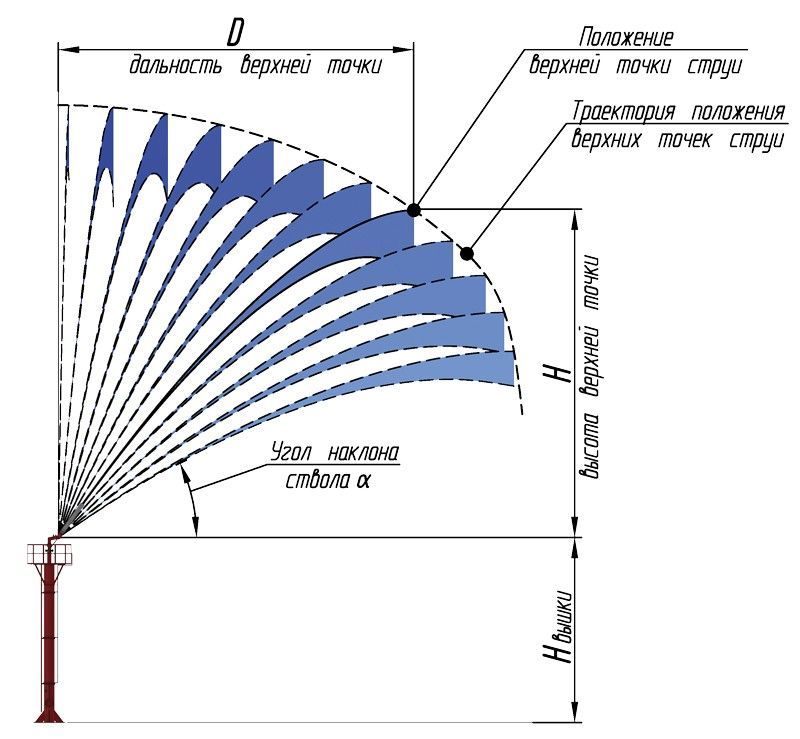

If it is necessary to evaluate the vertical application of jets by the fire monitors, the calculation and graphical method should be used with the dependency graphs of the height and range of the upper point on pressure.

Jet geometry diagram

Dependency graphs of the height and range of the upper point on pressure

To compare two graphs, select both values.

For foam makers LS-S20P, LS-S40P, LS-S60P, it is recommended to take values 20% less.