FOAM CONCENTRATE STORAGE AND PROPORTIONING SYSTEMS (SKhDP)

TU 4854-037-72410778-2015

General

Scope

Foam concentrate storage and proportioning system (SKhDP) is a complex of equipment, instrumentation and piping, which extinguishes fires providing the mixing of foam concentrate into the water stream in a percentage ratio corresponding to its volume concentration.

Modifications

Proportioning system with foam inductor M-FOI

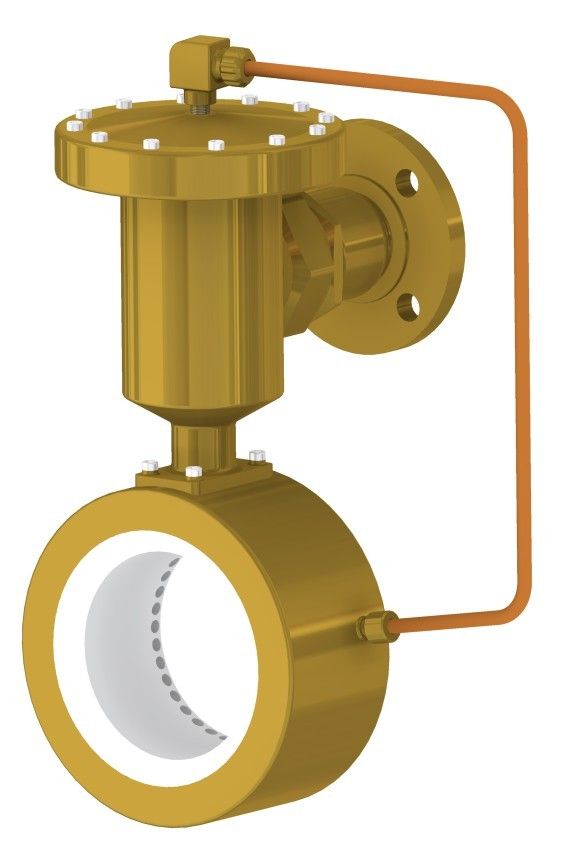

Proportioning system with the balanced pressure proproportioner M-BP

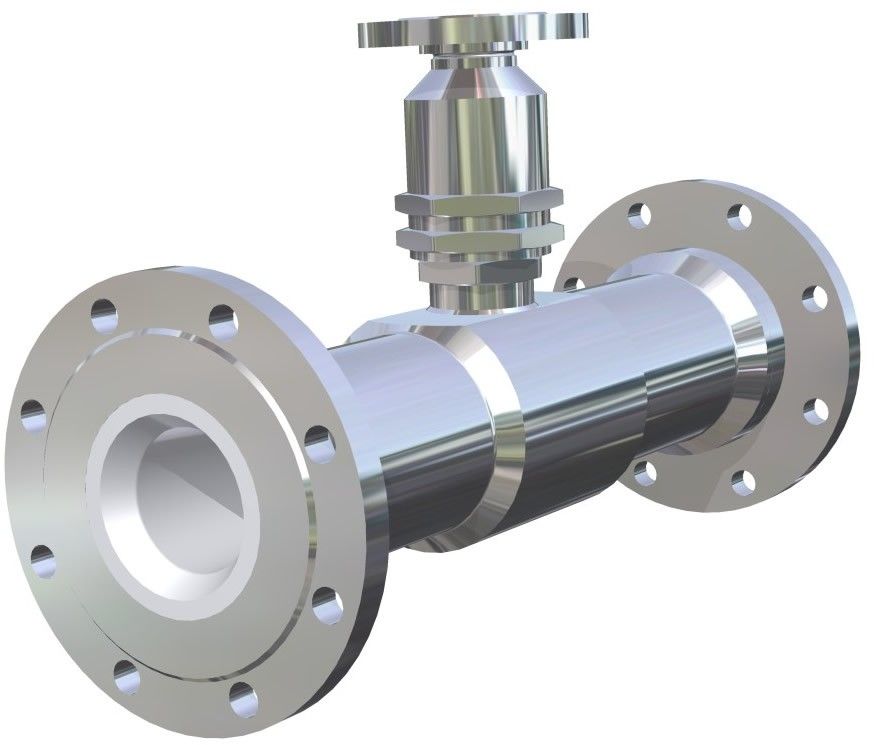

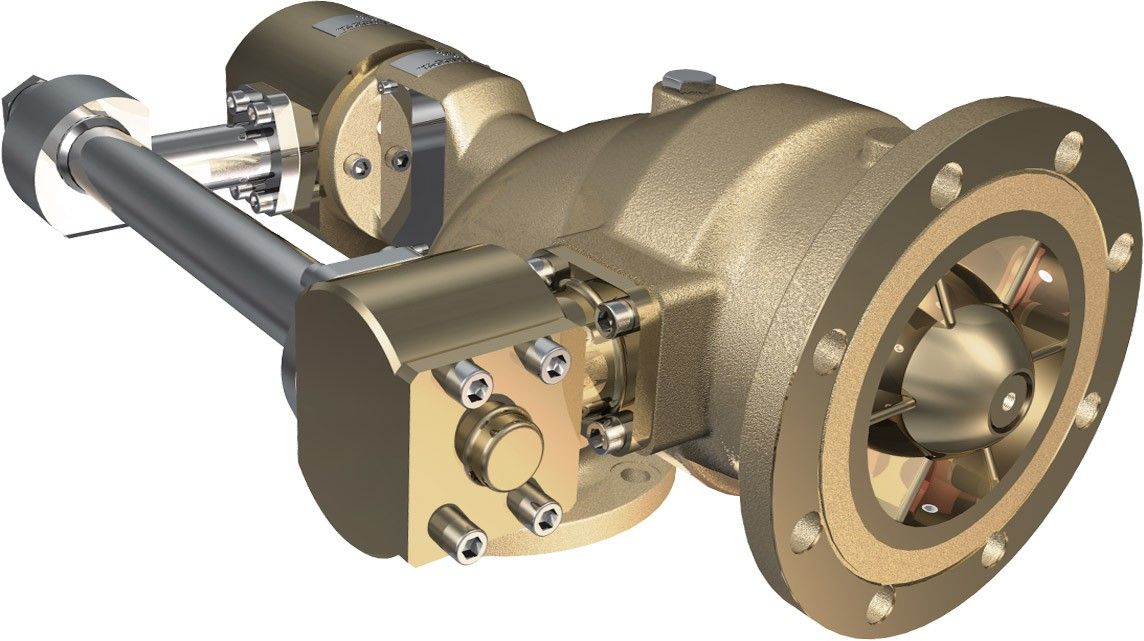

Proportioning system with the turbine inline proproportioner M-TU

Application area

Firefighting installations with one or two flow rates with minor length of distribution pipes.

Distinctive features:

- simple and reliable design;

- lack of moving and wearable parts.

Application restrictions:

- pressure loss 30% from the inlet pressure to the proportioner;

- kinematic viscosity no more than 30 cSt;

- low suction height;

- not more than two proportioners in the system.

Application area

Marine platforms, objects with sections of foam firefighting situated remotely from each other with central dosing system (objects of metallurgy, oil and energy industries), etc.

Distinctive features:

- wide range of flows and pressures;

- possible implementation in sprinkler installations;

- most economically feasible solution for objects with sections of foam firefighting situated remotely from each other.

Application area

The dosing systems are the most reliable and recommended for sites where a fire can cause significant social, economic and environmental damage, such as:

- warehouses and production of chemical hazardous substances, ammunition, rocket and nuclear fuel components;

- for offshore platforms, marine vessels;

- for production, transportation, storage, processing and transshipment of oil and petroleum products, remote oil fields, etc.

Also, the installation of systems based on turbine inline proportioners is recommended for the production and storage of expensive equipment that can easily be destroyed in a fire (enterprises of the space and aviation industries).

Due to its compact size, it is most advisable to use M-TU proportioners in tight spaces and block containers for fire suppression.

Distinctive features:

- simple and reliable design;

- minimal maintenance;

- long service life cycle (over 30 years).

Application restrictions:

- 6 % foam concentrate dosing not possible;

- kinematic viscosity no more than 30 cSt.

Specifications

Recommendations for the selection of proportioner manufacturing material

Name and designation of material

| Chemical composition | Material description | Application |

| Tin bronze. Compliance with GOST: BrO5C5S5. Chemical composition: Cu 83.0-87.0%, Sn 4.0-6.0%, Zn 4.0-6.0%, Pb 4.0-6.0%. | Tin bronzes are alloyed with zinc, nickel and phosphorus. Adding zinc in a proportion of up to 10% almost does not change the properties of bronzes, but makes them cheaper. Tin bronze with the addition of zinc is called the “Admiralty Bronze” and has increased corrosion resistance in sea water. Lead and phosphorus improve the antifriction properties of bronze and its machinability by cutting. | It is used in most cases when there are no additional requirements of standards. It is resistant to corrosion, including when exposed to hard industrial and sea water. It is used in the manufacture of low pressure valves, fittings for gas and water nipples, fittings for the oil industry, fittings and devices for fire extinguishing installations. |

| Алюми 10-4-4. Хими |

Хорошо сопро |

Объекты, где необходимы повы |

| Нержа |

Марка стали, представ |

Используется в производстве оборудования для химической промыш |

| Техни |

Основное досто |

Используется в хими |

| Нержа |

Нержа |

Подходит для исполь |

Design Information

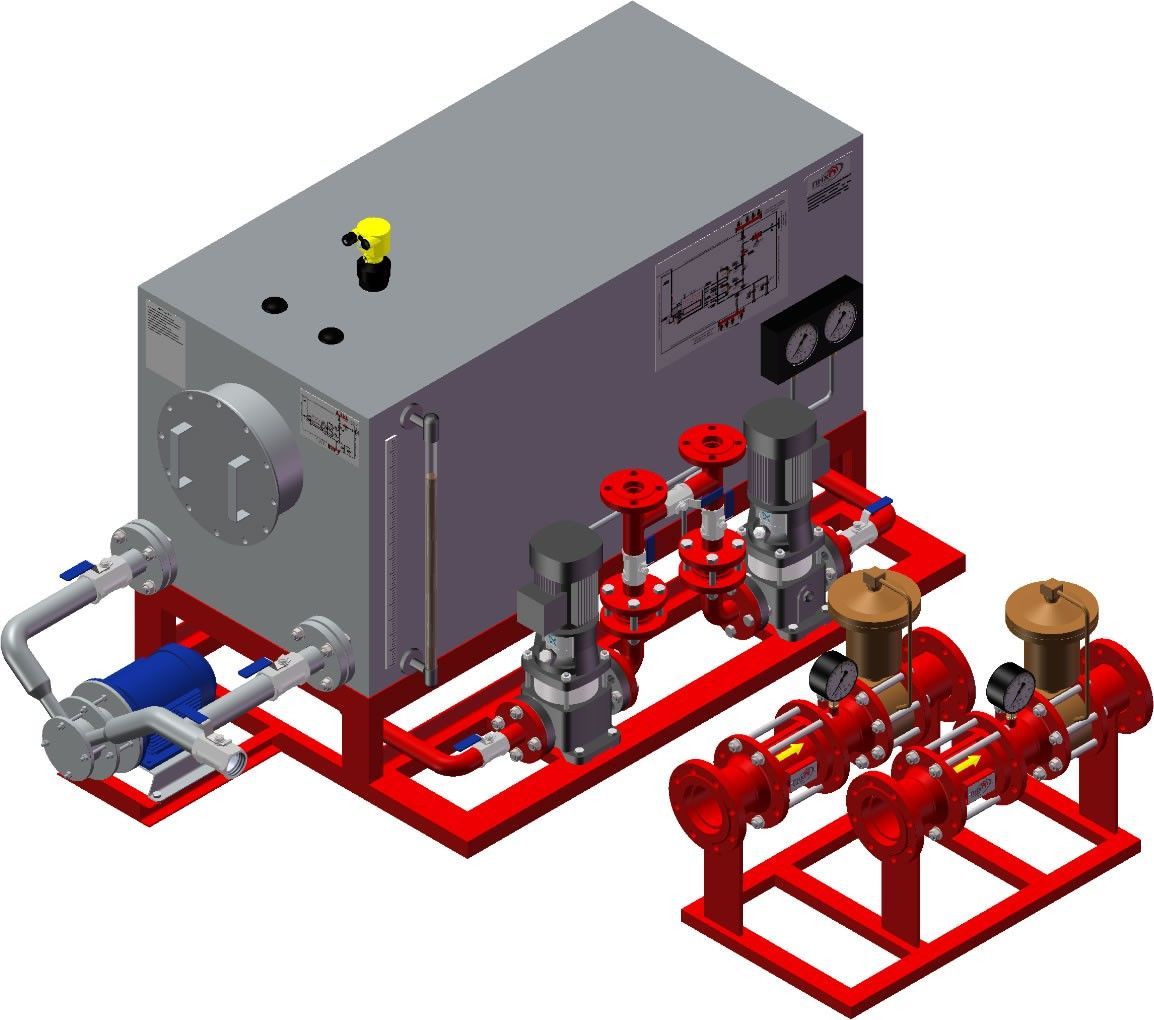

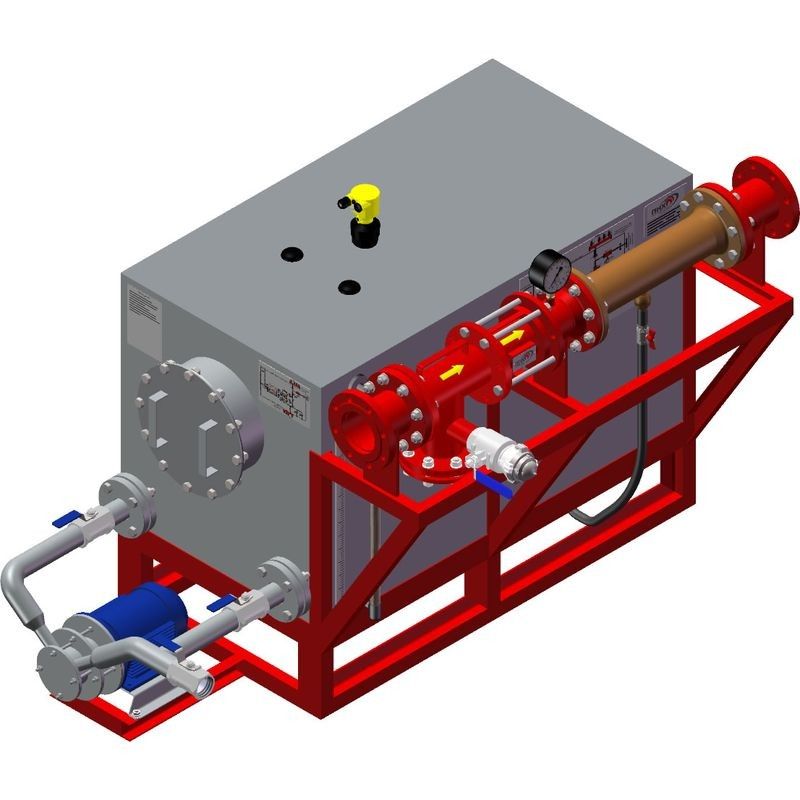

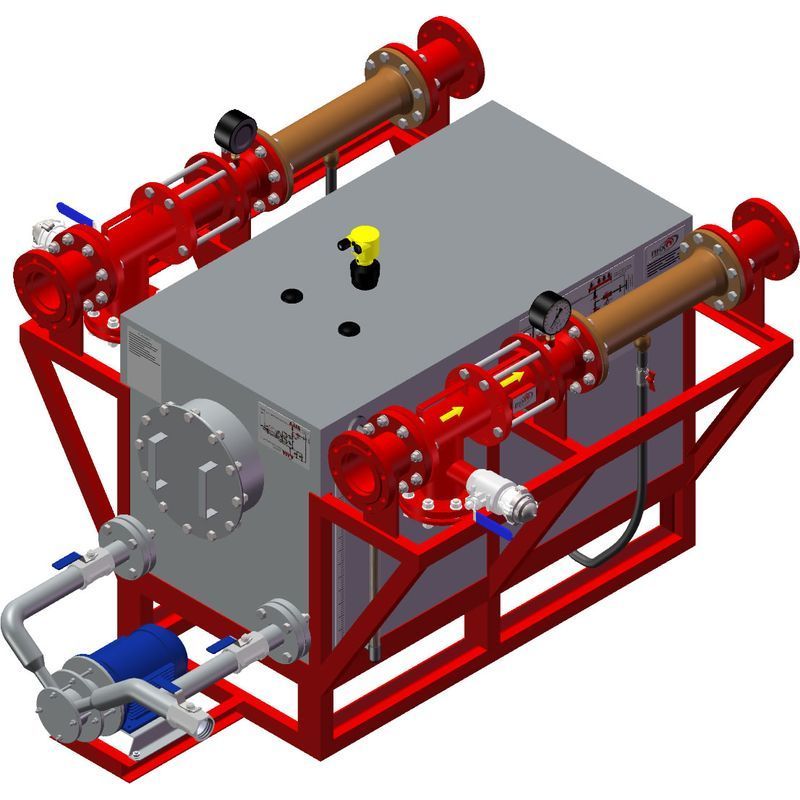

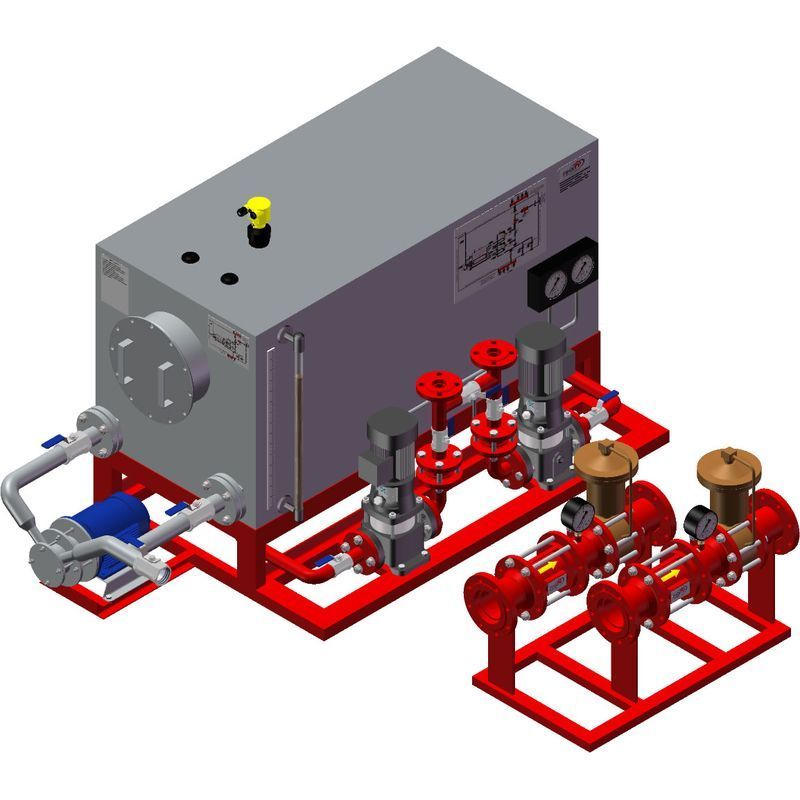

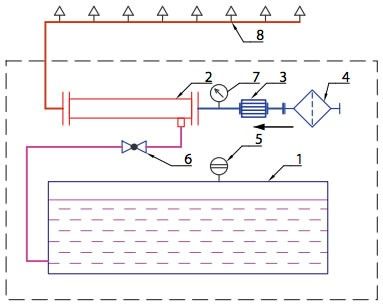

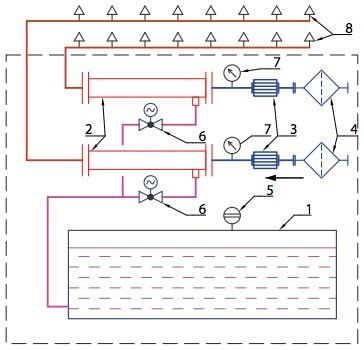

Typical schematic diagrams of foam concentrate storage and proportioning systems

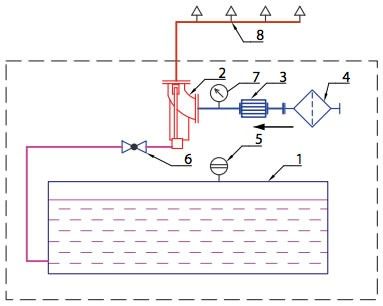

Typical diagrams of proportioning systems with foam inductors M-FOI

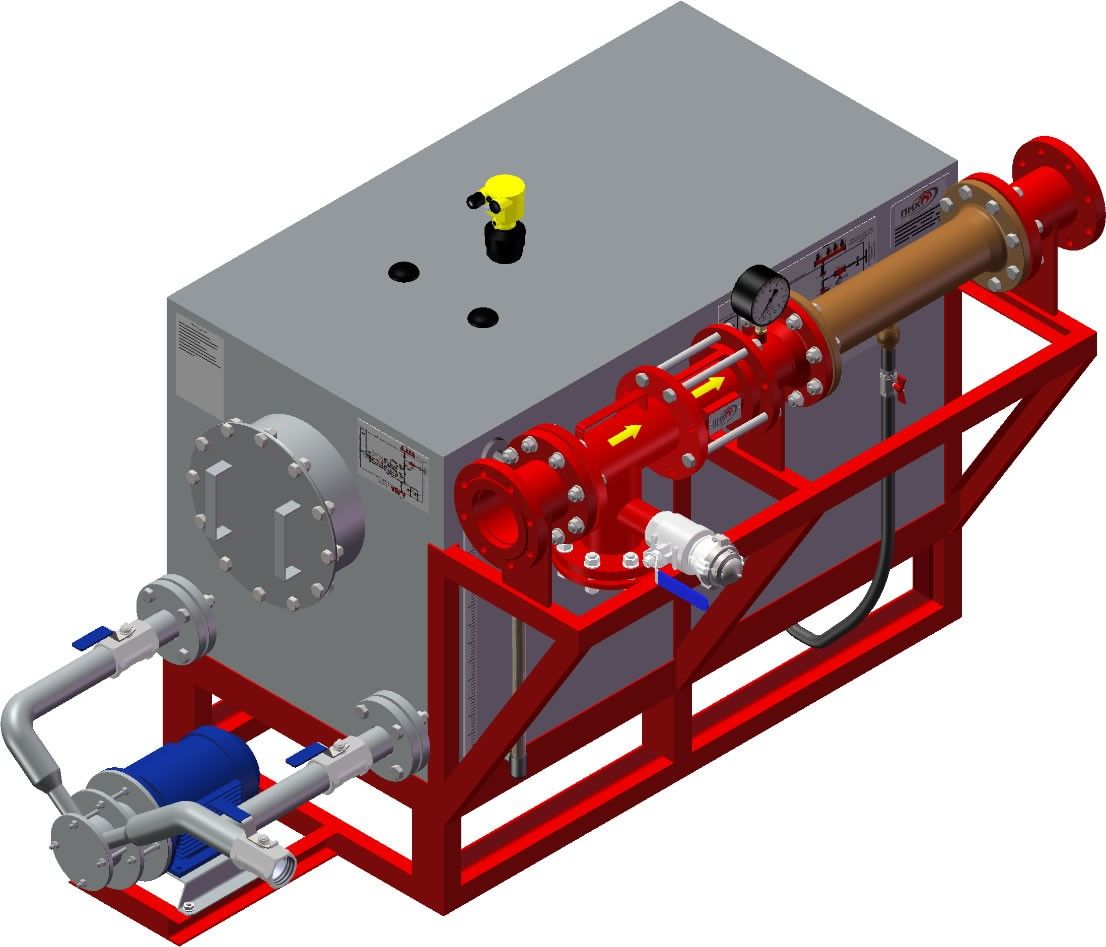

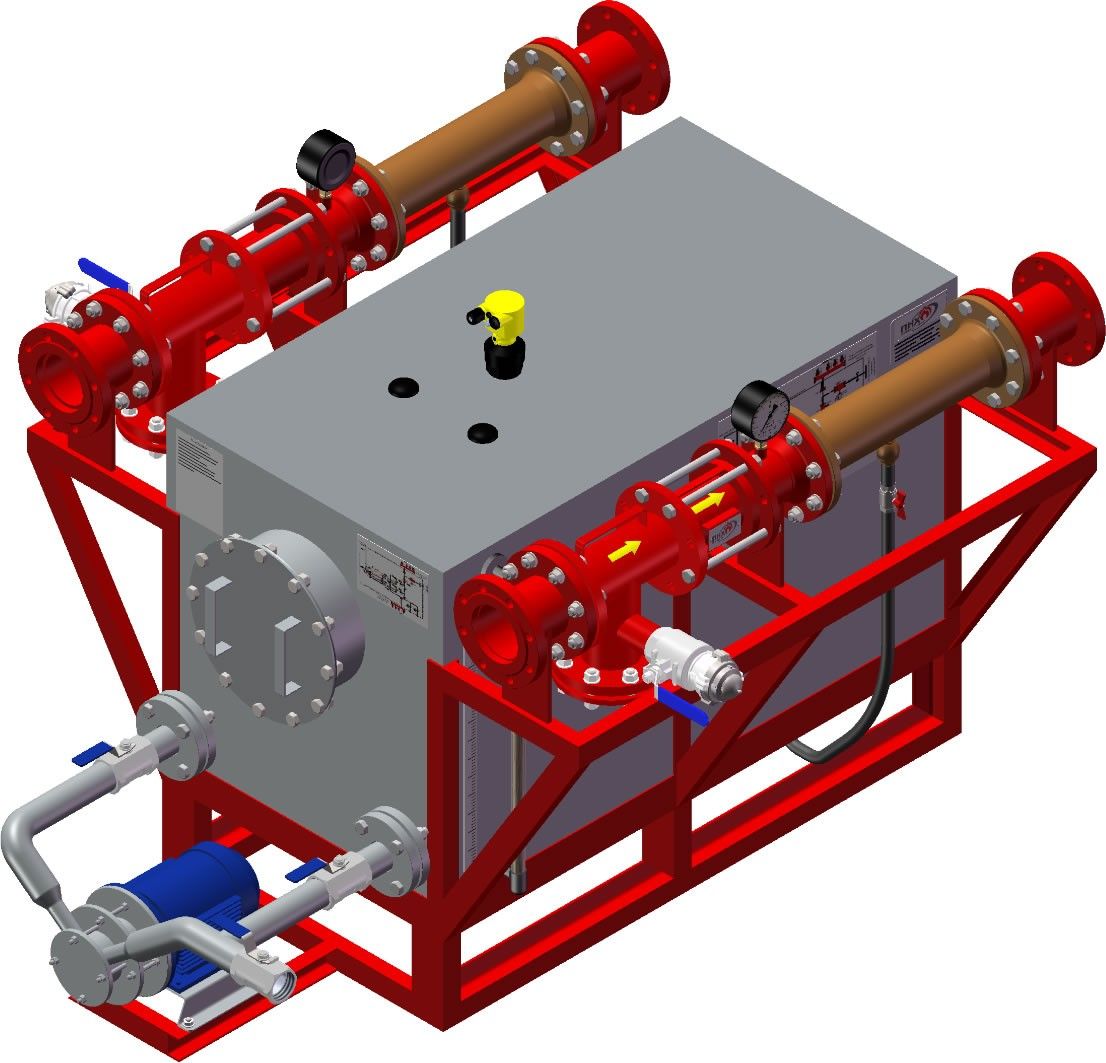

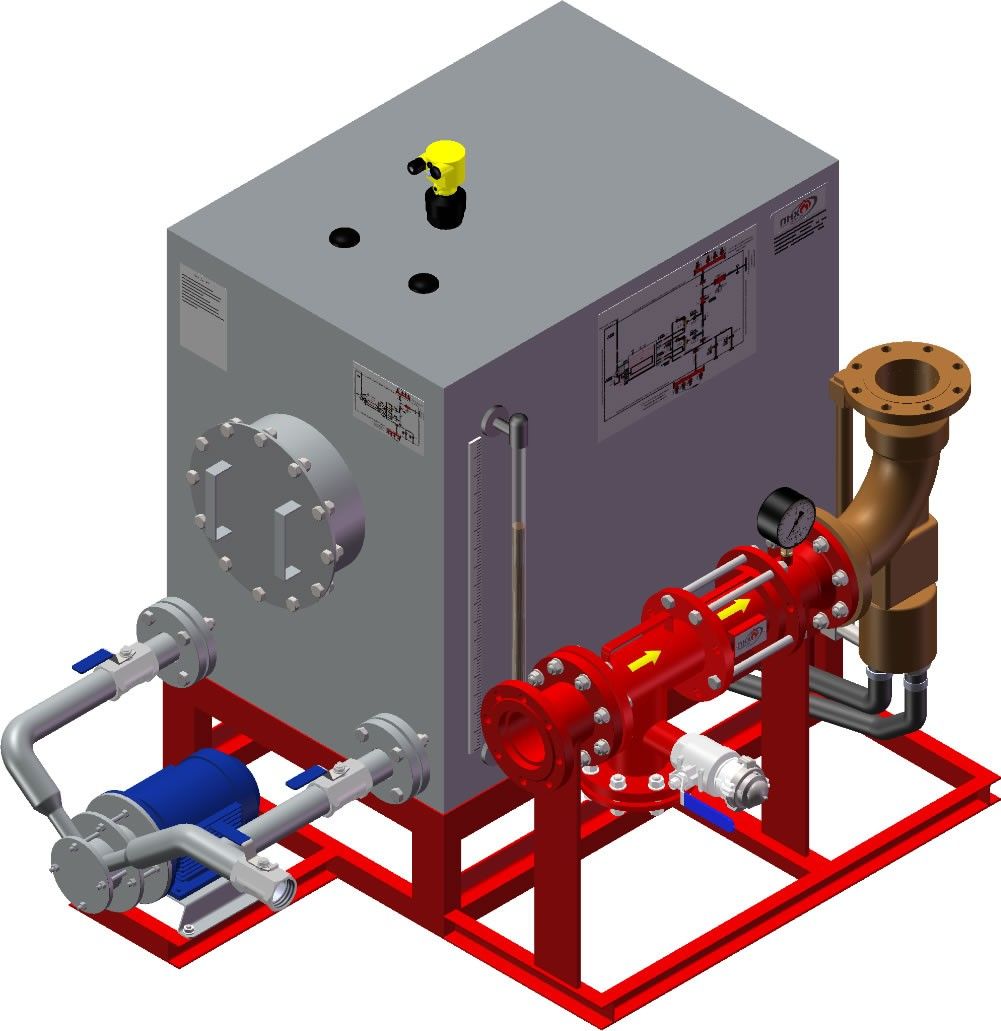

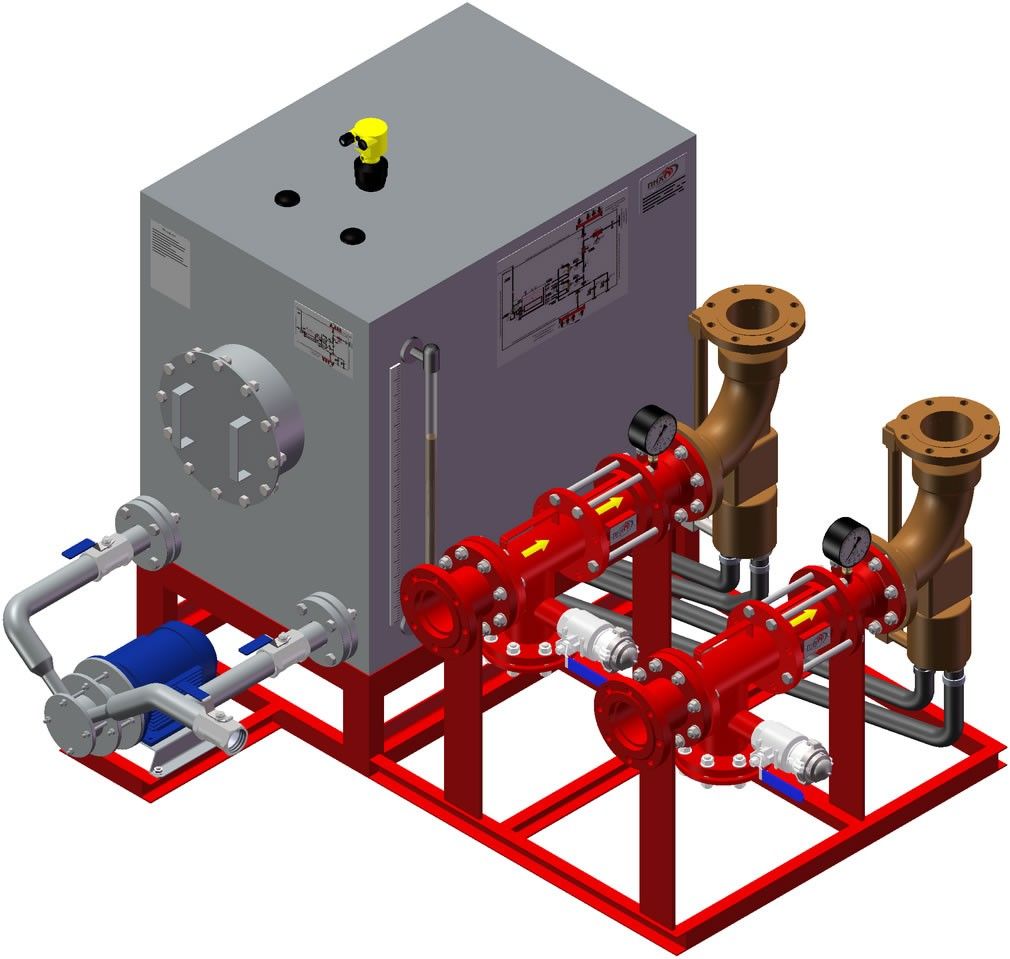

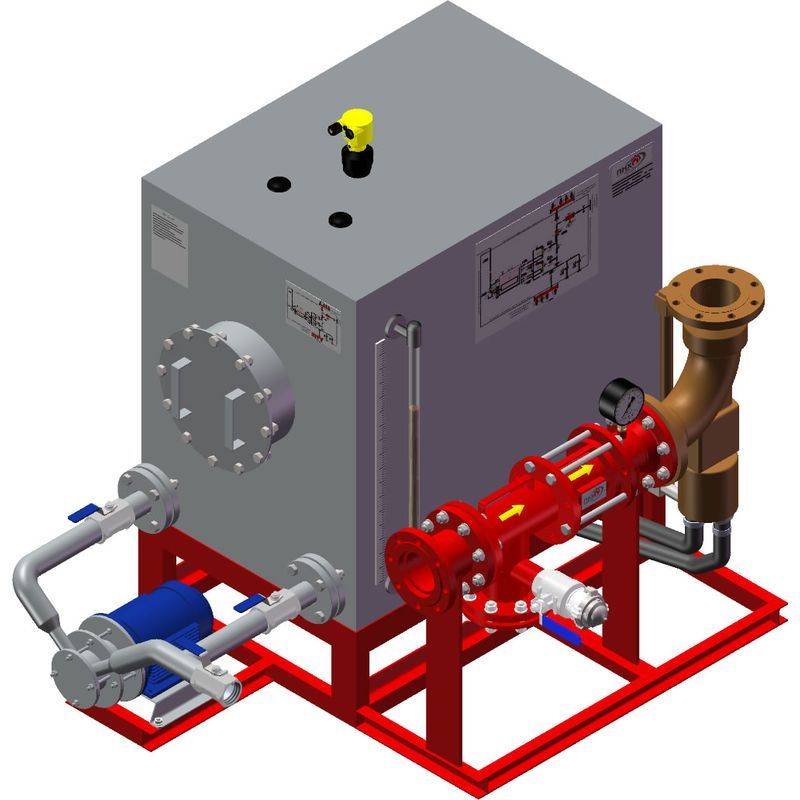

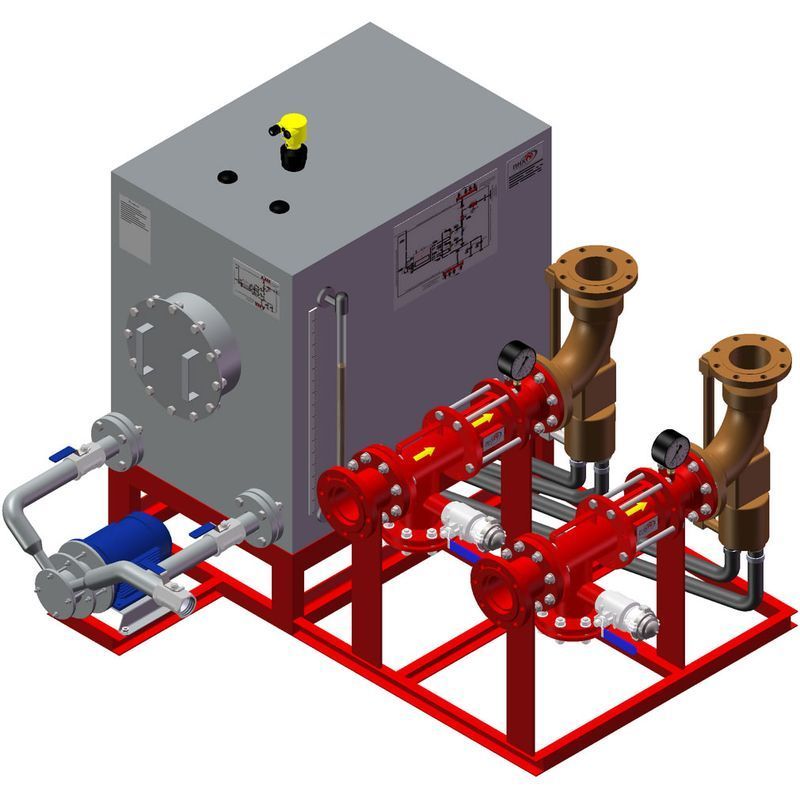

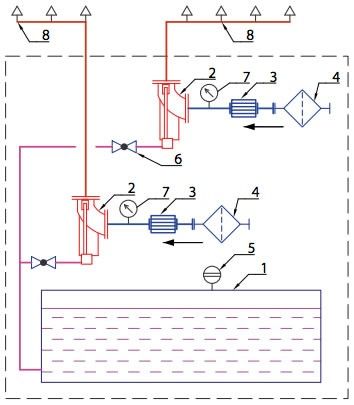

Typical schematic diagrams of proportioning systems with turbine inline proportioners M-TU

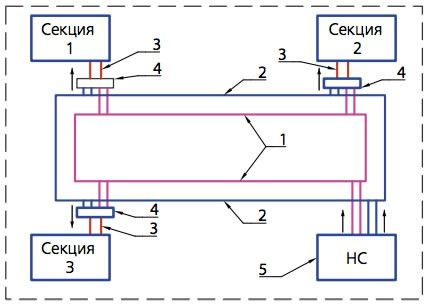

Typical schematic diagrams of proportioning systems with balanced pressure proportioners M-BP

1 – foam concentrate pipeline made of stainless steel or polymers;

2 – fire pipeline;

3 – solution supply piping (dry nipple in standby mode);

4 – block of balancing proportioners;

5 – pumping station with a foam concentrate central proportioning system.

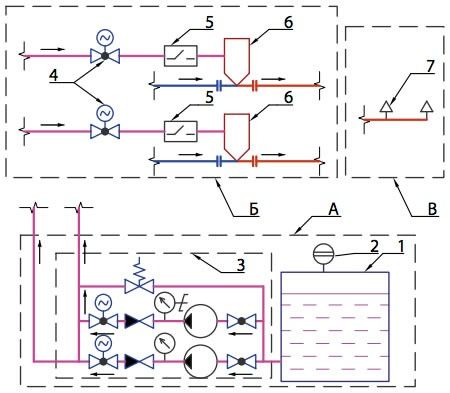

Typical diagram with central proportioning system and balanced pressure proportioners M-BP

A - central proportioning system;

1 – foam concentrate storing container;

2 – level gauge;

3 – pumping station for foam concentrate proportioning;

Б - balanced pressure proportioners;

4 – electric shutoff valve;

5 – flow switch;

6 – balanced pressure proportioner;

В – fire fighting section;

7 – water/foam nozzle.

Please contact the Pozhneftekhim Group design department specialists for the correct selection of proportioning systems, development of detailed technological schemes and layouts of SKhDP taking into account the design features of facilities.