FIXED FIRE PRESSURE PROPORTIONER FOAMIX (DPN-S)

Declaration of Conformity ТР ЕАЭС 043_2017 № RU Д-RU.РА01.В.66206/20

TU 4854-021-72410778-09

Purpose and scope

Purpose and scope

The fixed (stationary) fire pressure proportioner Foamix (DPN-S) is a device for dosing foam concentrate under pressure into a water stream in a pipeline and obtaining a 1%, 3% or 6% premix (concentration depending on the type of foam).

The Foamix fixed fire pressure proportioner DPN-S can be effectively used:

- as a part of fire extinguishing installations operating from mobile firefighting units (that is, in fire extinguishing installations where fire pump stations and foam concentrate preparation units are not provided);

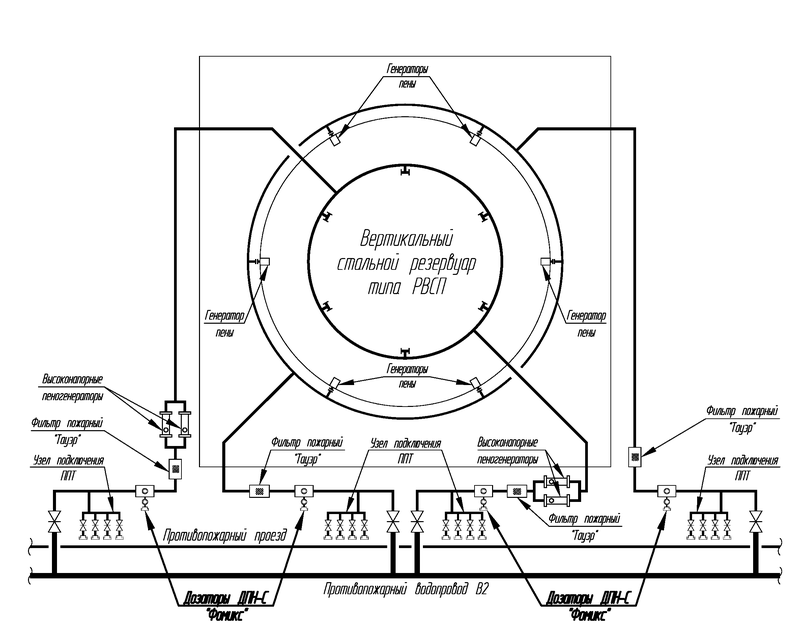

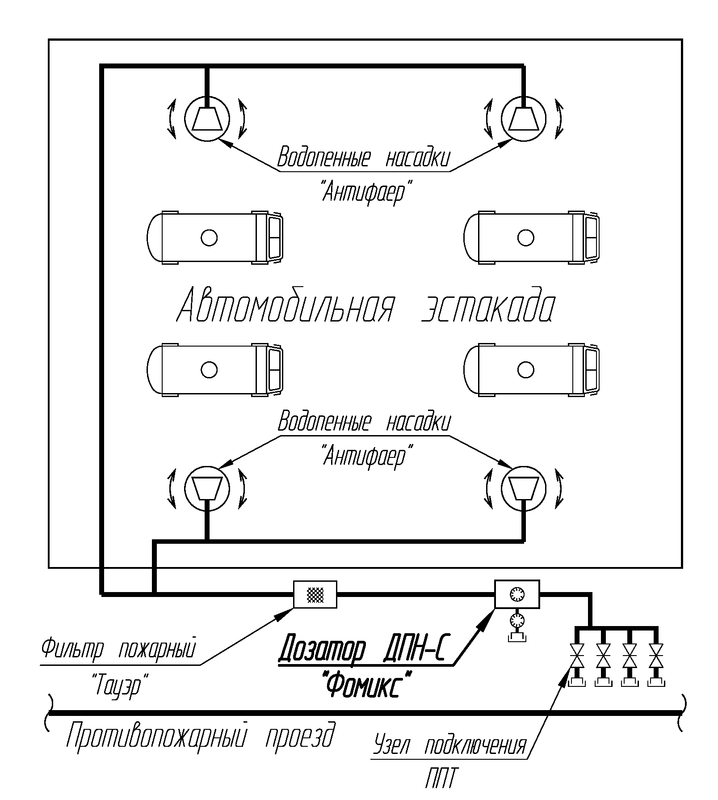

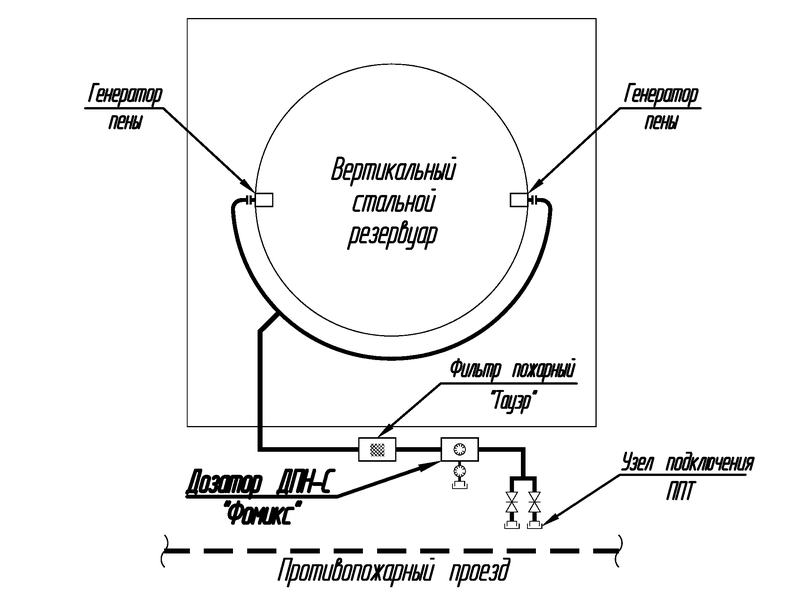

Diagram of fire extinguishing installation operating from mobile

firefighting units fit up with Foamix DPN-S

to protect a vertical steel oil storage tank with a volume of up to 5000 m³

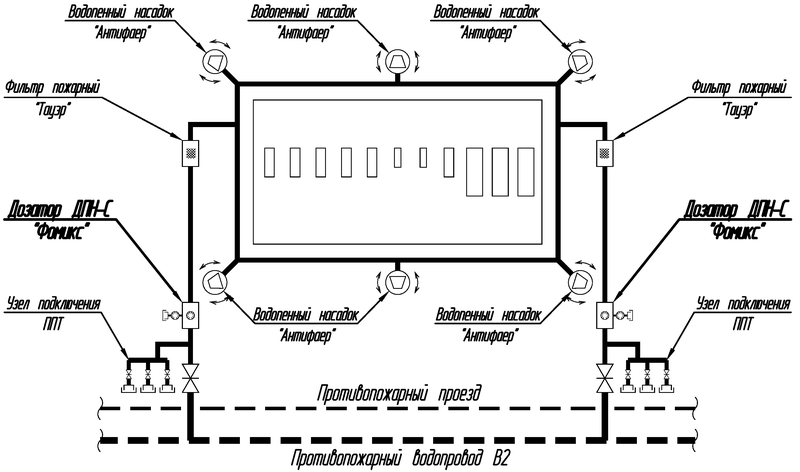

Diagram of the fire extinguishing installation

jointly operating with mobile firefighting units, equipped with Foamix DPN-S

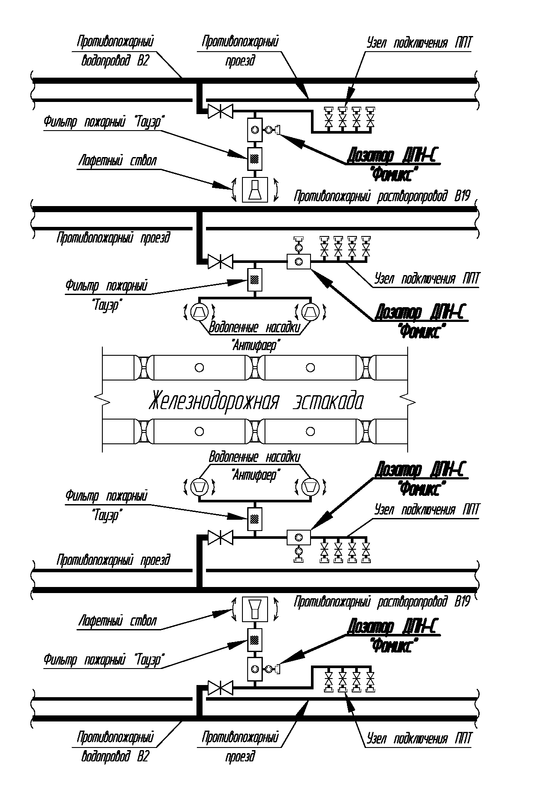

o protect a technological platform handling petroleum products

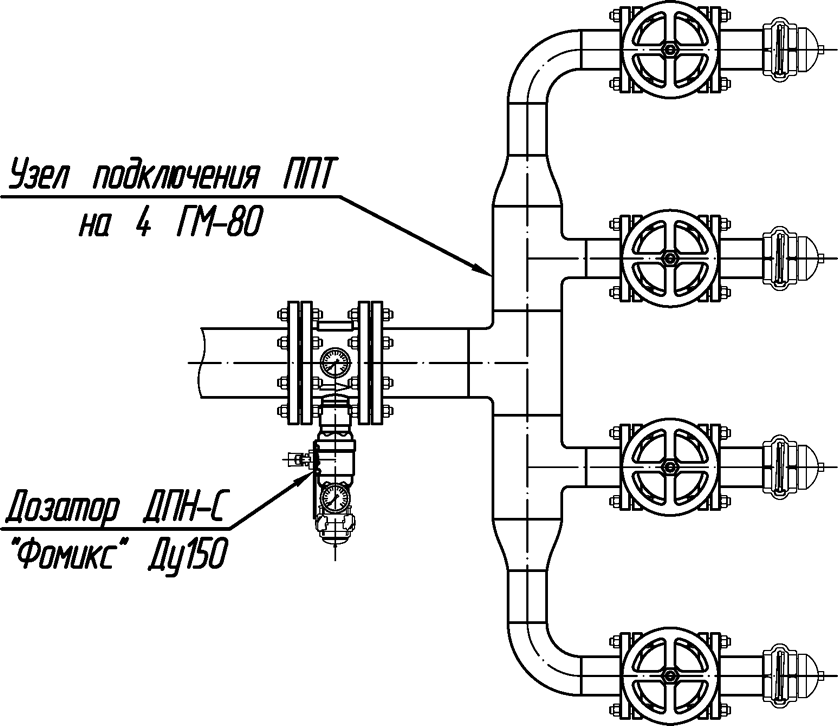

- as a part of fire extinguishing installations with fire hydrant manifolds. The fire hydrant manifolds are used to carry out foam attacks by fire and rescue units;

Diagram of the fire extinguishing installation for a vertical steel tank with a pontoon for storing petroleum products with a volume of 5000 m³ or more with fire hydrant manifolds for connecting mobile firefighting units, equipped with Foamix DPN-S

Diagram of the fire extinguishing installation for a railway rack with fire hydrant manifolds for connecting mobile firefighting units, equipped with Foamix DPN-S

Diagram of the fire extinguishing installation for a truck rack with fire hydrant manifolds for connecting mobile firefighting units, equipped with Foamix DPN-S

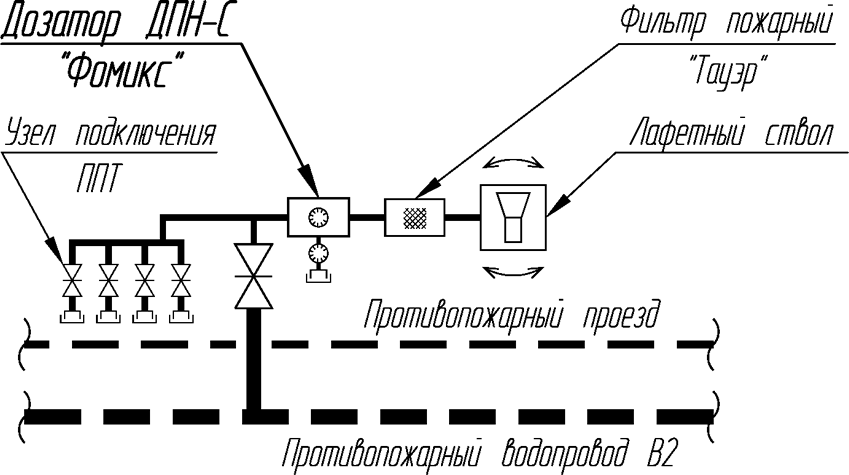

- as a part of fire hydrant manifolds for connecting mobile firefighting units, which are installed to supply water to fire monitors (hydromonitors);

Scheme of a fire monitor with a fire hydrant manifolds for connecting mobile firefighting units, equipped with Foamix DPN-S

- as a part of fire hydrant manifolds for connecting firefighting units for water intake from fire water pipelines installed on the territory of tank farms, on railway racks (if manifolds are connected to the water supply), at berth complexes for oil products transshipment, and at other facilities.

Four-nipple fire hydrant manifold for connecting mobile firefighting unit, equipped with Foamix DPN-S

Distinctive advantages

- possible dosing of 1%, 3% and 6% foam concentrate by the selection of position on the regulatory scale;

- available pressure gauges to comply with water supply and foam concentrate flow rate;

- proportioner and back-pressure valve manufactured of stainless steel;

- compactness.

Modifications

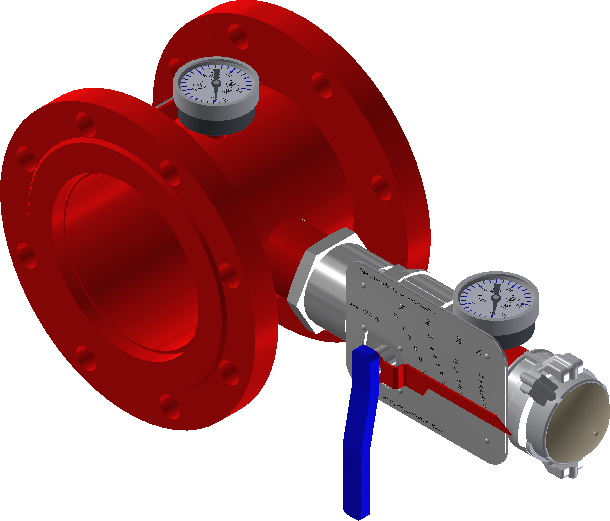

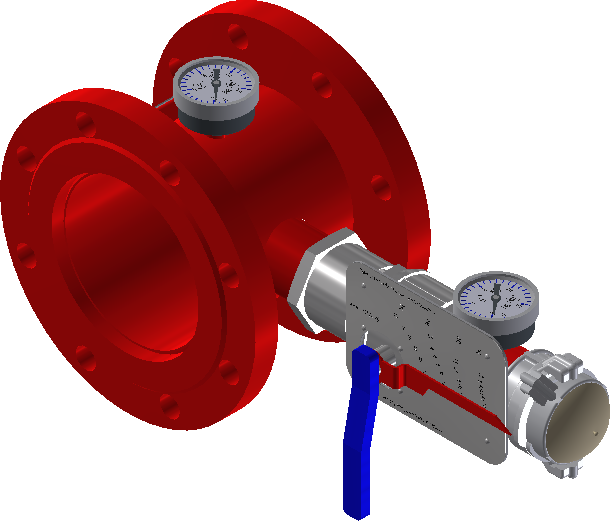

Foamix DPN-S, modification with flanges

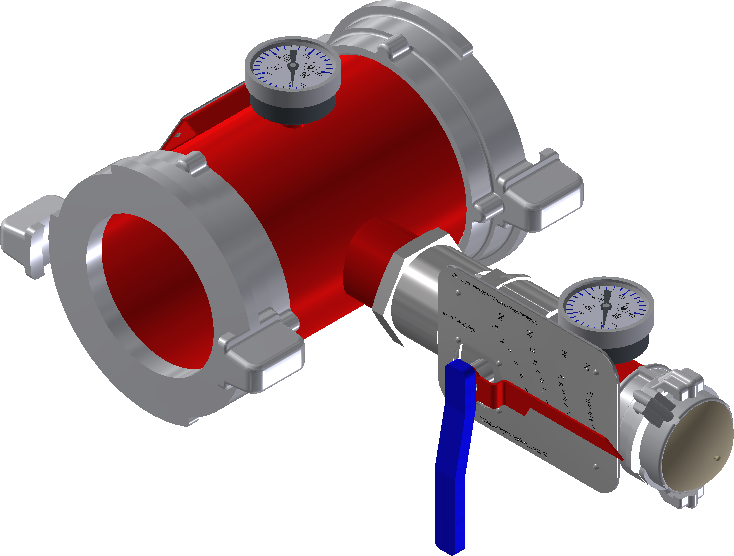

Foamix DPN-S, modification with coupling heads

Specifications

Materials of manufacture

In terms of resistance to climatic effects, the Foamix fixed fire pressure proportioners are manufactured in U, HL, UHL, T, OM modifications according to GOST 15150-69.

- Climatic modification U: case - steel 20 with anti-corrosion coating; metering unit, back-pressure valve - stainless steel.

- Climatic modification HL: case - steel 09G2S with anticorrosive coating; metering unit, back-pressure valve - stainless steel.

- Climatic modification T, OM: case, proportioning unit, back-pressure valve - stainless steel.

On request, all types of designs can be made of stainless steel.

Key Specifications

Рабочее давление, МПа 0,3–1,6 |

Дозирование пенообразователя 1 %, 3 %, 6 % |

Разность давления воды в корпусе и пенообразователя перед дозирующей диафрагмой, ΔР, МПа 0,1 |

Рабочий диапазон расходов воды 0–15 |

Тип полугайки ГМ для подачи пенообразователя ГМ-50 |

Срок эксплуатации, лет, не менее 10 |

Рабочее давление, МПа 0,3–1,6 |

Дозирование пенообразователя 1 %, 3 %, 6 % |

Разность давления воды в корпусе и пенообразователя перед дозирующей диафрагмой, ΔР, МПа 0,1 |

Рабочий диапазон расходов воды 0–25 |

Тип полугайки ГМ для подачи пенообразователя ГМ-50 |

Срок эксплуатации, лет, не менее 10 |

Рабочее давление, МПа 0,3–1,6 |

Дозирование пенообразователя 1 %, 3 %, 6 % |

Разность давления воды в корпусе и пенообразователя перед дозирующей диафрагмой, ΔР, МПа 0,1 |

Рабочий диапазон расходов воды 0–55 |

Тип полугайки ГМ для подачи пенообразователя ГМ-50 |

Срок эксплуатации, лет, не менее 10 |

Рабочее давление, МПа 0,3–1,6 |

Дозирование пенообразователя 1 %, 3 %, 6 % |

Разность давления воды в корпусе и пенообразователя перед дозирующей диафрагмой, ΔР, МПа 0,1 |

Рабочий диапазон расходов воды 0–95 |

Тип полугайки ГМ для подачи пенообразователя ГМ-50 |

Срок эксплуатации, лет, не менее 10 |

Рабочее давление, МПа 0,3–1,6 |

Дозирование пенообразователя 1 %, 3 %, 6 % |

Разность давления воды в корпусе и пенообразователя перед дозирующей диафрагмой, ΔР, МПа 0,1 |

Рабочий диапазон расходов воды 0–155 |

Тип полугайки ГМ для подачи пенообразователя ГМ-80 |

Срок эксплуатации, лет, не менее 10 |

Рабочее давление, МПа 0,3–1,6 |

Дозирование пенообразователя 1 %, 3 %, 6 % |

Разность давления воды в корпусе и пенообразователя перед дозирующей диафрагмой, ΔР, МПа 0,1 |

Рабочий диапазон расходов воды 0–220 |

Тип полугайки ГМ для подачи пенообразователя ГМ-80 |

Срок эксплуатации, лет, не менее 10 |

| Indicator name | Indicator value | |||||

| DPN-80S | DPN-100S | DPN-150S | DPN-200S | DPN-250S | DPN-300S | |

| Operating pressure, MPa | 0,3–1,6 | |||||

| Foam concentrate proportioning rate | 1 %, 3 %, 6 % | |||||

| The difference between the water pressure in the case and the foam concentrate upstream of the metering diaphragm, ΔР, MPa | 0,1 | |||||

| Operating range of water flow rate through the proportioner-mixer, l/s | 0–15 | 0–25 | 0–55 | 0–95 | 0–155 | 0–220 |

| Type of half-nut GM for supplying foam concentrate | GM-50 | GM-80 | ||||

| Service life, years, min | 10 | |||||

Operating procedure

When applying Foamix DPN-S as a part of the piping manifolds for connecting mobile firefighting units, the control valve shall be set on a scale to a position corresponding to the estimated water flow rate through this fire hydrant manifold and the concentration of the foam concentrate used. When applying a foam concentrate from a foam fire extinguishing truck or other source, the pressure of the foam concentrate should be kept at 0.1 MPa more than the pressure in the pipeline where Foamix DPM-S is installed (controlled by pressure gauges included in the DPN-S design).

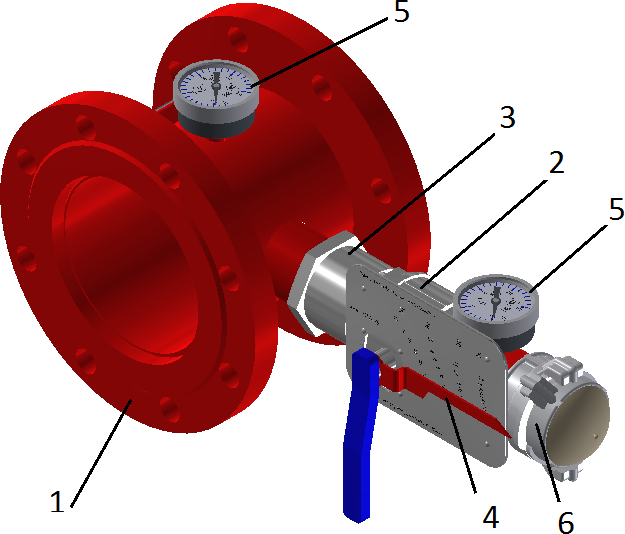

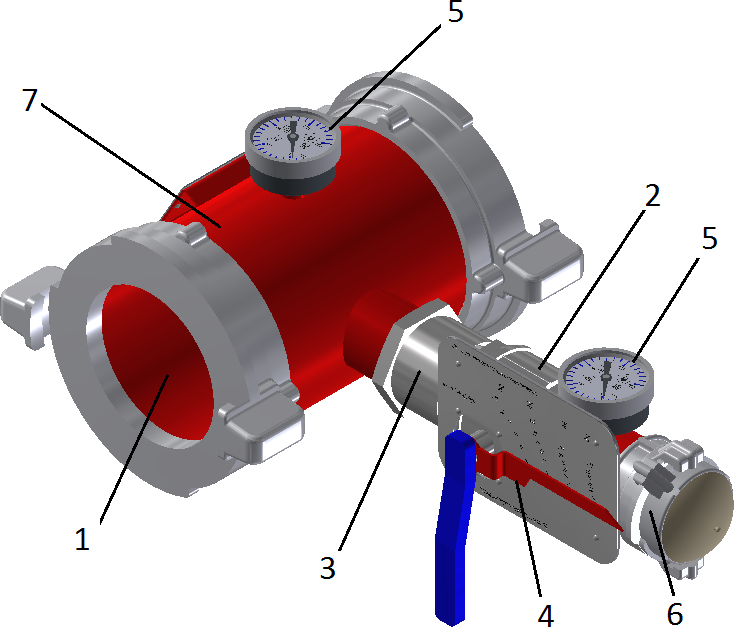

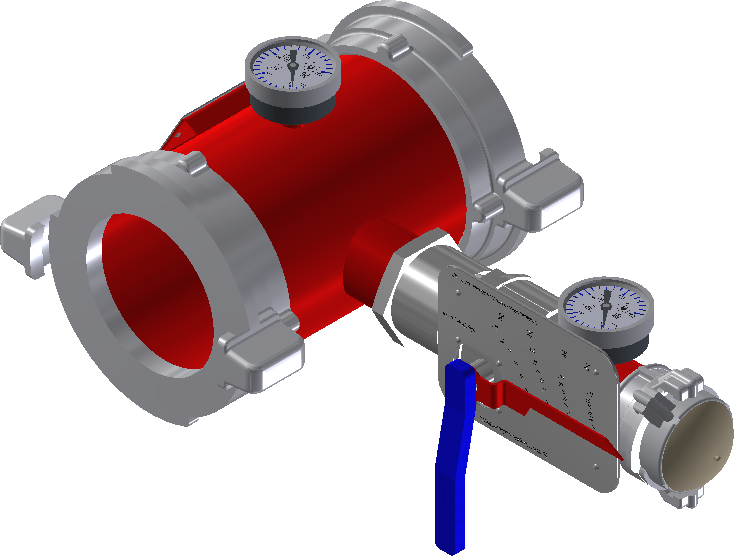

Key components

1 – case with flanges (on request for DPN-80S and DPN-150S - with half nuts GM-80 and GM-150, respectively);

2 – control valve;

3 – back-pressure valve;

4 – adjustment scale;

5 – manometers;

6 – head GM-50 (GM-80) with GZ-50 (GZ-80);

7 – handle (for modification with GM).