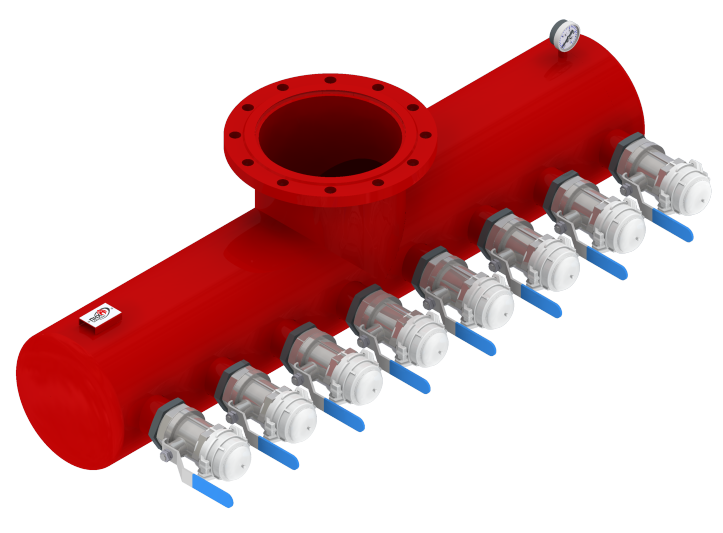

FIRE HYDRANT MANIFOLD FOR FIREFIGHTING EQUIPMENT (UPT)

TU 4854-032-72410778-2015

General

Purpose and scope

The fire hydrant manifold for firefighting equipment (UPT) is used to supply (withdraw) water or a foam concentrate solution in fire extinguishing installations or to equip the supply pipelines of stationary fire extinguishing means (fire monitors, hydraulic monitors, foam generators, etc.).

As a rule, the use of the fire hydrant manifold implyes the connection of fire hose lines and the supply of water through them from mobile firefighting equipment to a fire extinguishing installation or the withdrawal of the foam concentrate premix from a foam fire extinguishing installation and its supply using manual, transportable, mobile foam or universal fire nozzles or foam generators to fire or accident scene.

In terms of resistance to climatic effects, UPT corresponds to the U, HL, UHL, T, OM modifications according to GOST 15150-69.

Ambient temperature range: from minus 60 ºС to plus 50 ºС.

Distinctive advantages

- factory manufacturing;

- equipment with manometers and a drain cock (when ordering);

- built-in bases for supports (when ordering);

- use of stop valves and GM connecting fire heads of high quality.

Modifications

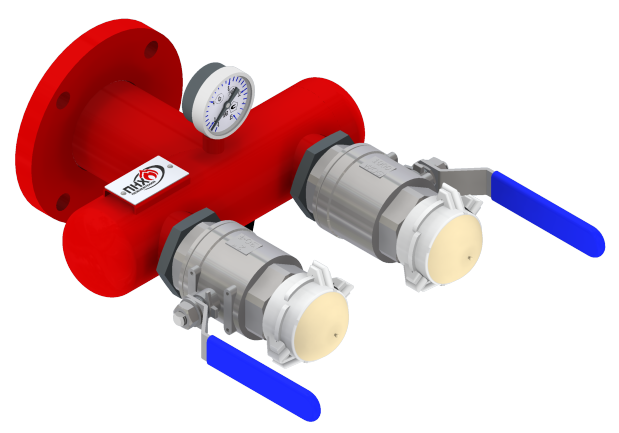

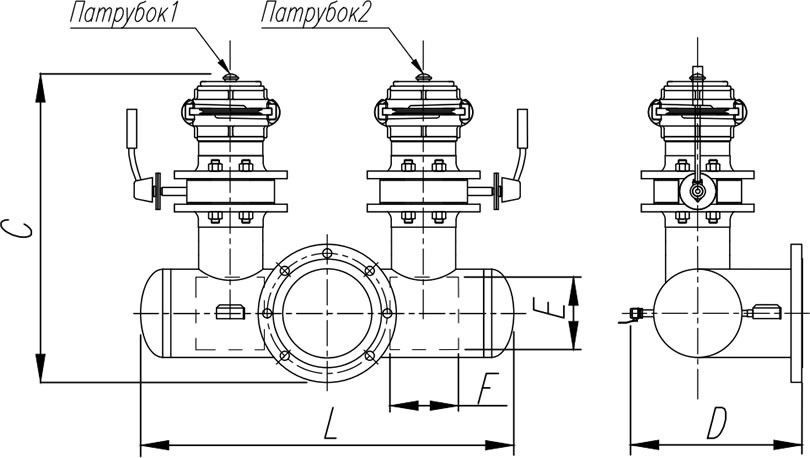

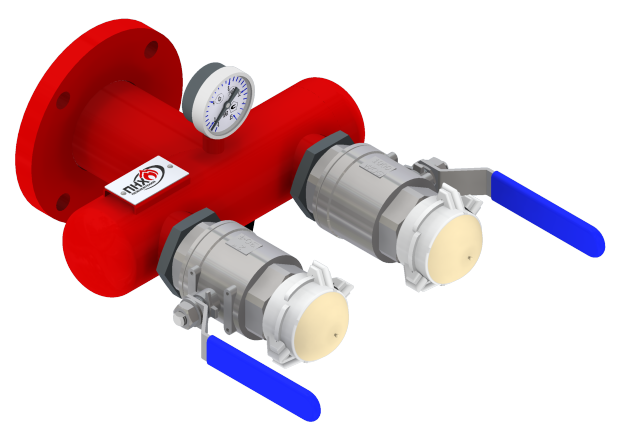

UPT designed for two GM-50/GM-80

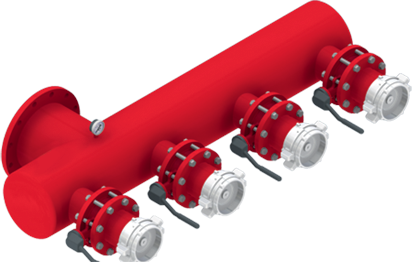

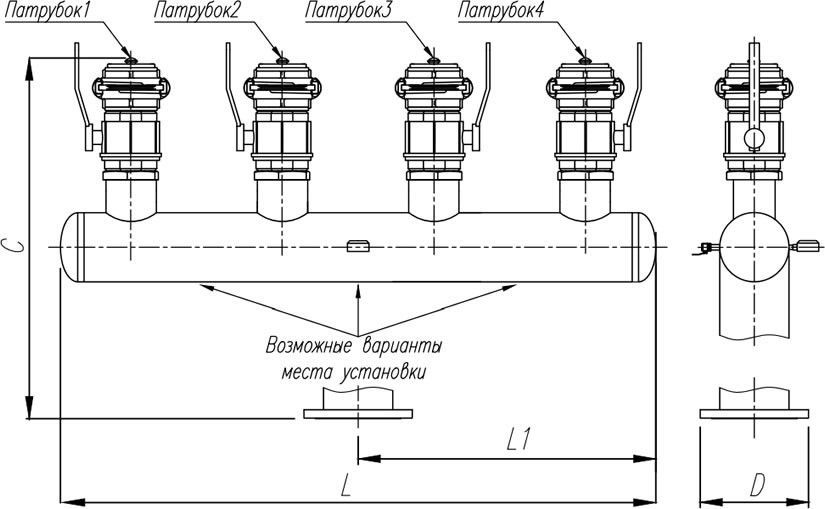

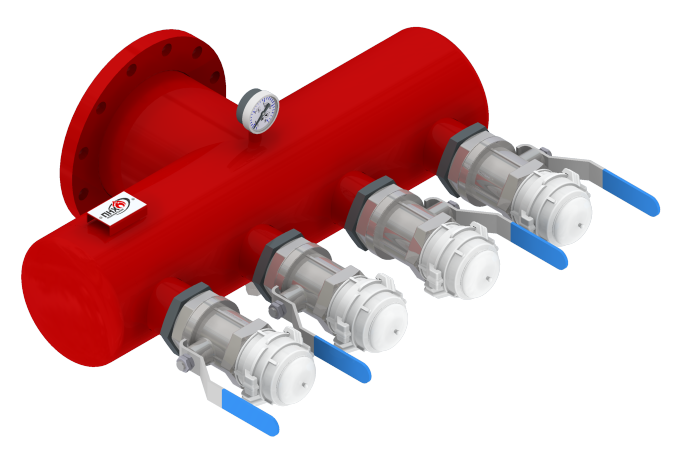

UPT designed for four GM-50/GM-80

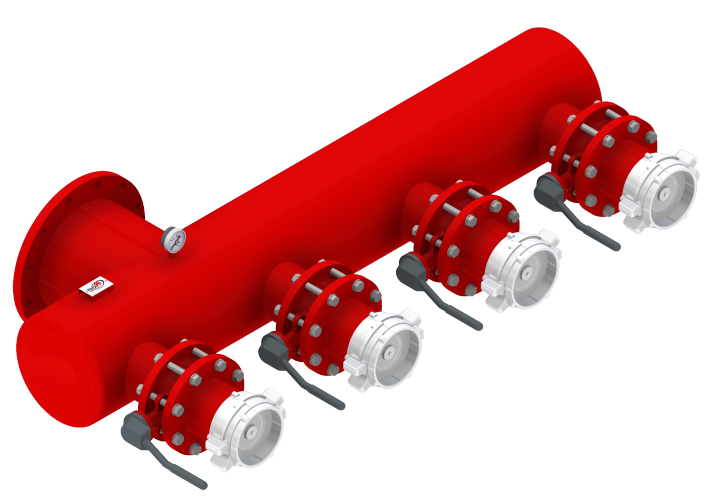

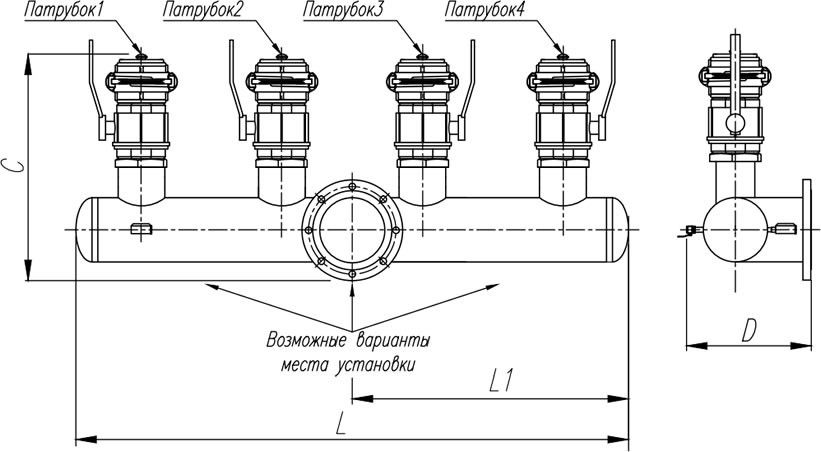

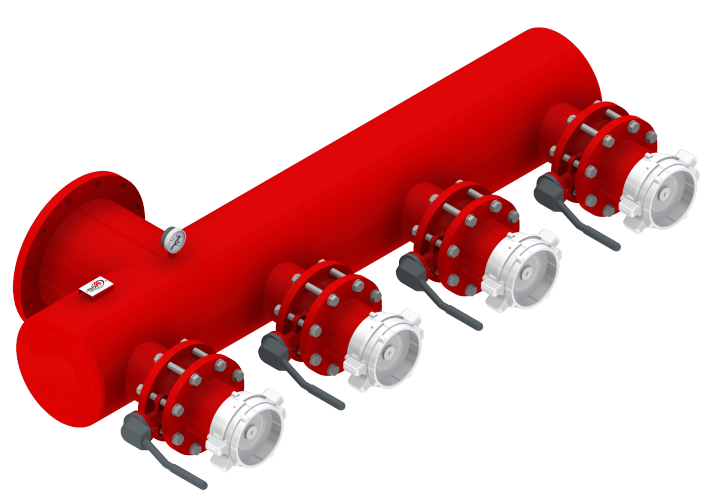

UPT designed for four GM-150

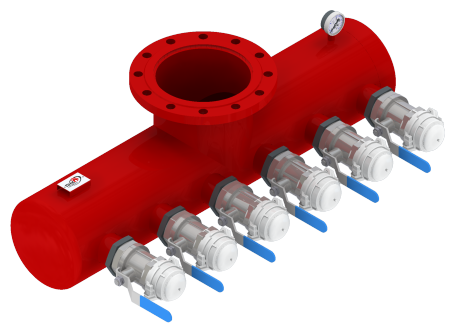

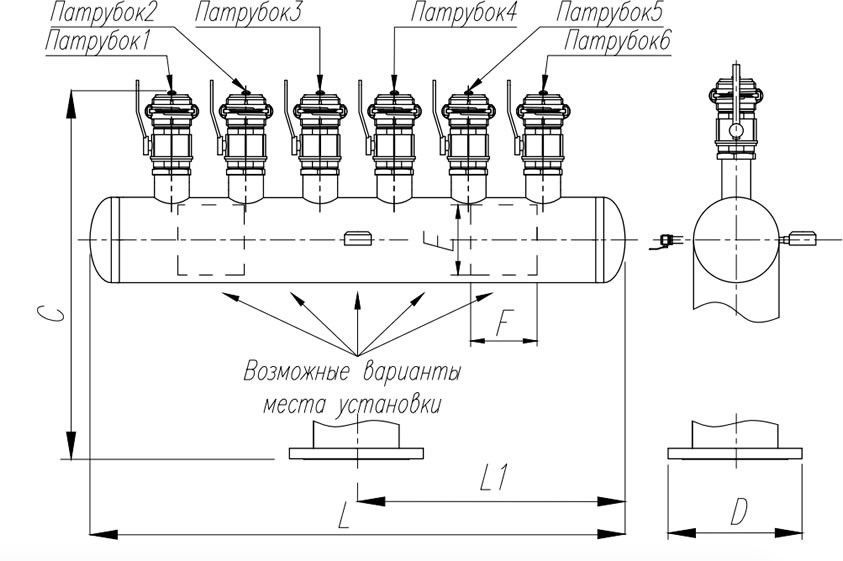

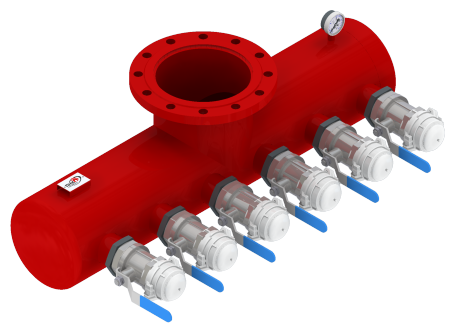

UPT designed for six GM-80

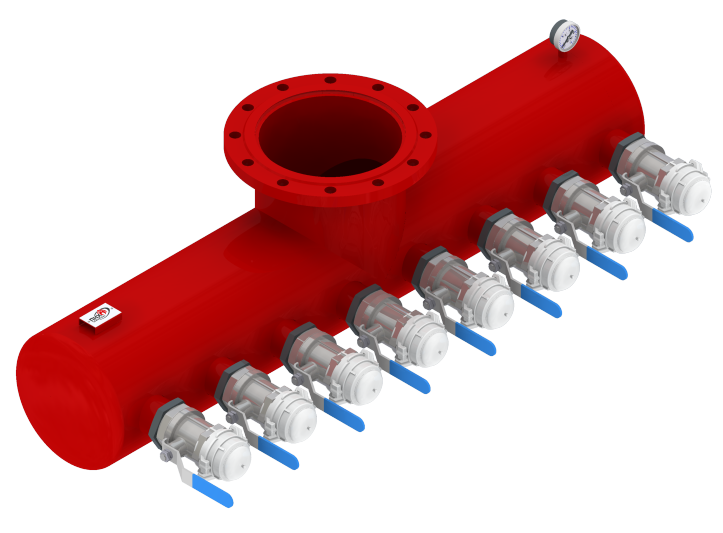

UPT designed for eight GM-80

Выбрать Overall dimensions and weight of the UPT

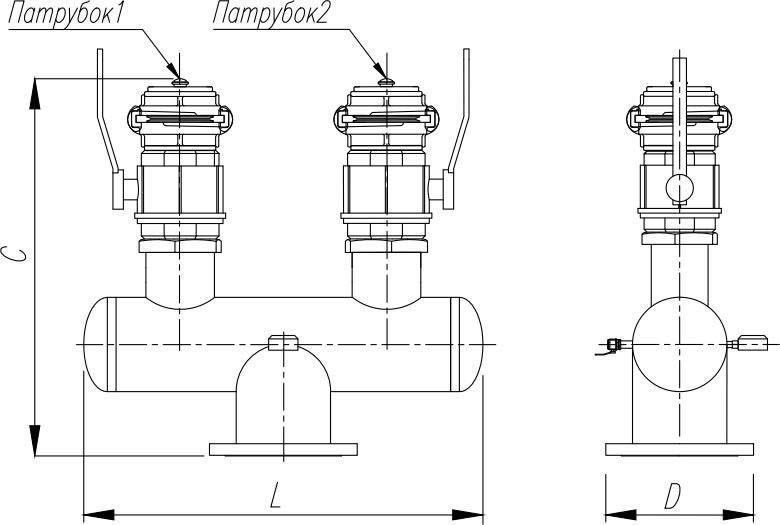

Overall dimensions and weight of theUPT designed for eight GM-80, the position of the fire hydrant manifold is direct straight

| Overall dimensions and weight of theUPT designed for eight GM-80 (direct straight) | ||||

| L, mm | C, mm | D, mm | Weight, kg | |

| UPT for two GM-50 | 390 | 400 | 194 | 18 |

| UPT for two GM-80 | 470 | 490 | 215 | 24 |

Выбрать Overall dimensions and weight of the UPT

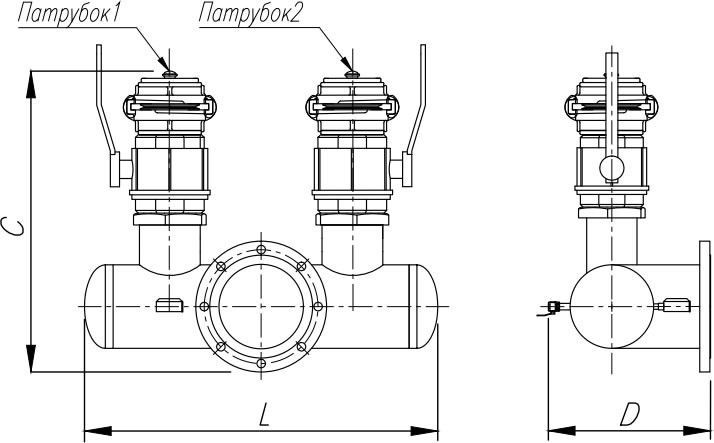

Overall dimensions and weight of the UPT for four GM-50 and GM-80, the position of the fire hydrant manifold is direct straight

L, mm 800 |

L1, mm 226 |

C, mm 450 |

D, mm 215 |

Weight, kg 40 |

L, mm 800 |

L1, mm 400 |

C, mm 450 |

D, mm 215 |

Weight, kg 40 |

L, mm 800 |

L1, mm 574 |

C, mm 450 |

D, mm 215 |

Weight, kg 40 |

L, mm 920 |

L1, mm 260 |

C, mm 620 |

D, mm 280 |

Weight, kg 60 |

L, mm 920 |

L1, mm 460 |

C, mm 620 |

D, mm 280 |

Weight, kg 60 |

L, mm 920 |

L1, mm 660 |

C, mm 620 |

D, mm 280 |

Weight, kg 60 |

| Overall dimensions and weight of the UPT for four GM-50 and GM-80 (direct straight) | |||||||

| L, mm | L1, mm | C, mm | D, mm | Weight, kg | |||

| UPT for four GM-50, fire hydrant monitor between 1 and 2 branch pipes | 800 | 226 | 450 | 215 | 40 | ||

| UPT for four GM-50, fire hydrant monitor between 2 and 3 branch pipes | 400 | ||||||

| UPT for four GM-50, fire hydrant monitor between 3 and 4 branch pipes | 574 | ||||||

| UPT for four GM-80, fire hydrant monitor between 1 and 2 branch pipes | 920 | 260 | 620 | 280 | 60 | ||

| UPT for four GM-80, fire hydrant monitor between 2 and 3 branch pipes | 460 | ||||||

| UPT for four GM-80, fire hydrant monitor between 3 and 4 branch pipes | 660 | ||||||

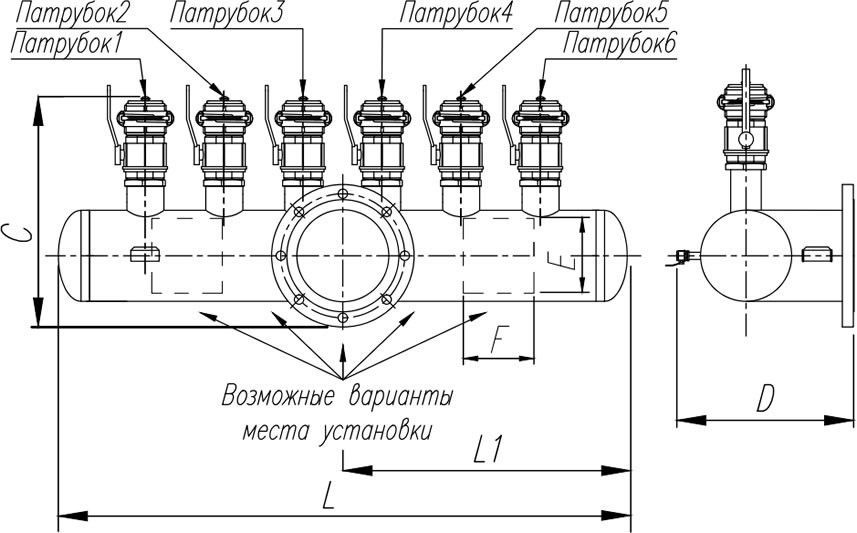

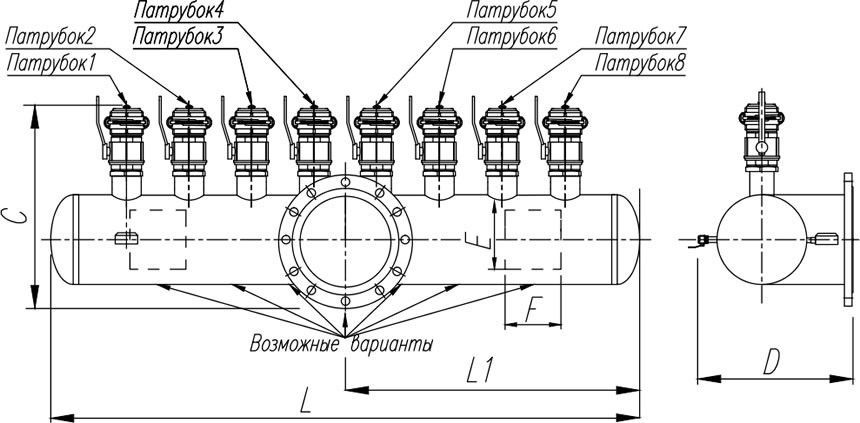

Выбрать Overall dimensions and weight of the UPT

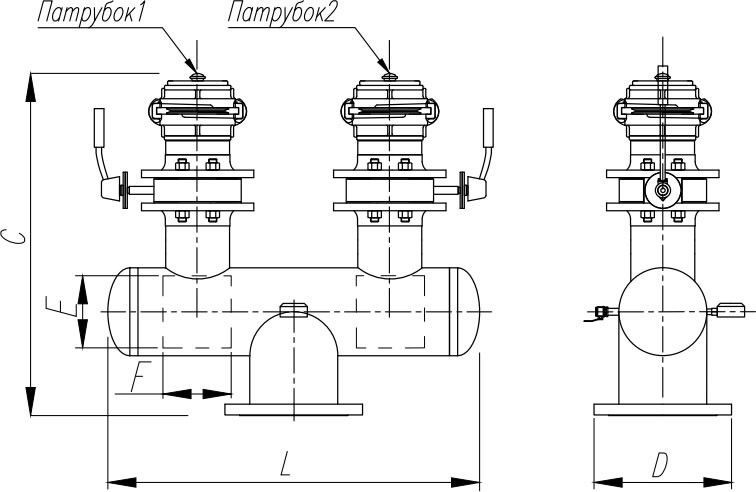

Overall dimensions and weight of the UPT for four GM-150, the position of the fire hydrant manifold is direct straight

L, mm 1970 |

L1, mm 477 |

C, mm 800 |

D, mm 405 |

E, mm 200 |

F, mm 170 |

Weight, kg 270 |

L, mm 1970 |

L1, mm 985 |

C, mm 800 |

D, mm 405 |

E, mm 200 |

F, mm 170 |

Weight, kg 270 |

L, mm 1970 |

L1, mm 1493 |

C, mm 800 |

D, mm 405 |

E, mm 200 |

F, mm 170 |

Weight, kg 270 |

| Overall dimensions and weight of the UPT for four GM-150 (direct straight) | |||||||

| L, mm | L1, mm | C, mm | D, mm | E, mm | F, mm | Weight, kg | |

| UPT for four GM-150, fire hydrant monitor between 1 and 2 branch pipes | 1970 | 477 | 800 | 405 | 200 | 170 | 270 |

| UPT for four GM-150, fire hydrant monitor between 2 and 3 branch pipes | 985 | ||||||

| UPT for four GM-150, fire hydrant monitor between 3 and 4 branch pipes | 1493 | ||||||

In the drawing, the dotted line shows two embedded points with the size ExF mm for the weld support.

Выбрать Overall dimensions and weight of the UPT

Overall dimensions and weight of the UPT for six GM-80, the position of the fire hydrant manifold is direct straight

L, mm 1370 |

L1, mm 285 |

C, mm 690 |

D, mm 405 |

E, mm 200 |

F, mm 170 |

Weight, kg 110 |

L, mm 1370 |

L1, mm 485 |

C, mm 690 |

D, mm 405 |

E, mm 200 |

F, mm 170 |

Weight, kg 110 |

L, mm 1370 |

L1, mm 685 |

C, mm 690 |

D, mm 405 |

E, mm 200 |

F, mm 170 |

Weight, kg 110 |

L, mm 1370 |

L1, mm 885 |

C, mm 690 |

D, mm 405 |

E, mm 200 |

F, mm 170 |

Weight, kg 110 |

L, mm 1370 |

L1, mm 1085 |

C, mm 690 |

D, mm 405 |

E, mm 200 |

F, mm 170 |

Weight, kg 110 |

| Overall dimensions and weight of the UPT for six GM-80 (direct straight) | |||||||

| L, mm | L1, mm | C, mm | D, mm | E, mm | F, mm | Weight, kg | |

| UPT for six GM-80, fire hydrant monitor between 1 and 2 branch pipes | 1370 | 285 | 690 | 405 | 200 | 170 | 110 |

| UPT for six GM-80, fire hydrant monitor between 2 and 3 branch pipes | 485 | ||||||

| UPT for six GM-80, fire hydrant monitor between 3 and 4 branch pipes | 685 | ||||||

| UPT for six GM-80, fire hydrant monitor between 4 and 5 branch pipes | 885 | ||||||

| UPT for six GM-80, fire hydrant monitor between 5 and 6 branch pipes | 1085 | ||||||

In the drawing, the dotted line shows two embedded points with the size ExF mm for the weld support.

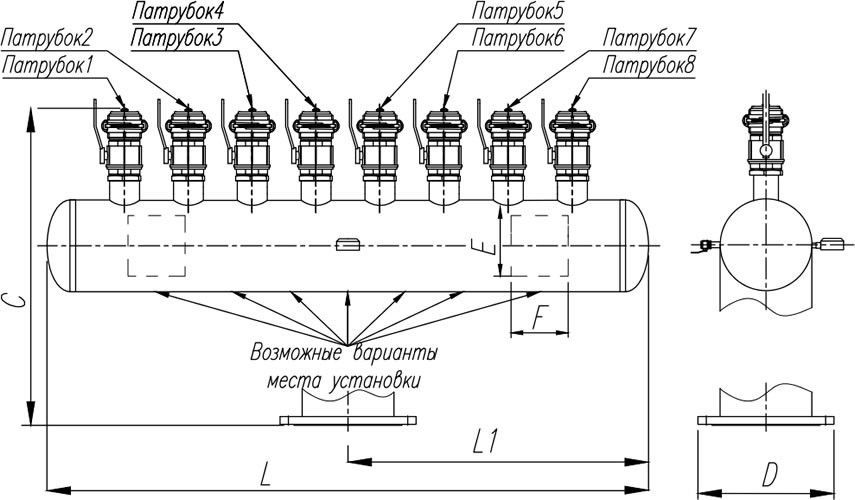

Выбрать Overall dimensions and weight of the UPT

Overall dimensions and weight of the UPT for eight GM-80, the position of the fire hydrant manifold is direct straight

L, mm 1790 |

L1, mm 295 |

C, mm 750 |

D, mm 460 |

E, mm 200 |

F, mm 170 |

Weight, kg 200 |

L, mm 1790 |

L1, mm 495 |

C, mm 750 |

D, mm 460 |

E, mm 200 |

F, mm 170 |

Weight, kg 200 |

L, mm 1790 |

L1, mm 695 |

C, mm 750 |

D, mm 460 |

E, mm 200 |

F, mm 170 |

Weight, kg 200 |

L, mm 1790 |

L1, mm 895 |

C, mm 750 |

D, mm 460 |

E, mm 200 |

F, mm 170 |

Weight, kg 200 |

L, mm 1790 |

L1, mm 1095 |

C, mm 750 |

D, mm 460 |

E, mm 200 |

F, mm 170 |

Weight, kg 200 |

L, mm 1790 |

L1, mm 1295 |

C, mm 750 |

D, mm 460 |

E, mm 200 |

F, mm 170 |

Weight, kg 200 |

L, mm 1790 |

L1, mm 1495 |

C, mm 750 |

D, mm 460 |

E, mm 200 |

F, mm 170 |

Weight, kg 200 |

| Overall dimensions and weight of the UPT for eight GM-80 (direct straight) | |||||||

| L, mm | L1, mm | C, mm | D, mm | E, mm | F, mm | Weight, kg | |

| UPT for eight GM-80, fire hydrant monitor between 1 and 2 branch pipes | 1790 | 295 | 750 | 460 | 200 | 170 | 200 |

| UPT for eight GM-80, fire hydrant monitor between 2 and 3 branch pipes | 495 | ||||||

| UPT for eight GM-80, fire hydrant monitor between 3 and 4 branch pipes | 695 | ||||||

| UPT for eight GM-80, fire hydrant monitor between 4 and 5 branch pipes | 895 | ||||||

| UPT for eight GM-80, fire hydrant monitor between 5 and 6 branch pipes | 1095 | ||||||

| UPT for eight GM-80, fire hydrant monitor between 6 and 7 branch pipes | 1295 | ||||||

| UPT for eight GM-80, fire hydrant monitor between 7 and 8 branch pipes | 1495 | ||||||

In the drawing, the dotted line shows two embedded points with the size ExF mm for the weld support.

Specifications

Materials of manufacture

- Climatic modification U: steel 20 with anti-corrosion coating.

- Climatic modification HL, UHL: steel 09G2S with anti-corrosion coating.

- Climatic modification T, OM for operation on sea water: stainless steel.

- Climatic modifications U, HL, UHL on request can be made of stainless steel.

Key Specifications

| Indicator name | Indicator value | ||

| for GM-50 | for GM-80 | for GM-150 | |

| Nominal pressure, MPa | 1,6 | ||

| Test pressure, MPa | 2 | ||

| Estimated throughput per branch pipe (taking into account hydraulic losses in hose lines), l/s | 5 | 10 | 35 |

| Type of stop valves used to complete UPT* | ball full-way valve | butterfly valve | |

*Note. On request, the UPT can be equipped with wedge valves or other shut-off valves.

Mounting flange dimensions

| UPT type | Mounting flange type |

| UPT for two GM-50 | Flange 80-16-01-1 GOST 33259-2015 |

| UPT for two GM-80 | Flange 100-16-01-1 GOST 33259-2015 |

| UPT for two GM-150 | Flange 200-16-01-1 GOST 33259-2015 |

| UPT for four GM-50 | Flange 100-16-01-1 GOST 33259-2015 |

| UPT for four GM-80 | Flange 150-16-01-1 GOST 33259-2015 |

| UPT for four GM-150 | Flange 250-16-01-1 GOST 33259-2015 |

| UPT for six GM-80 | Flange 250-16-01-1 GOST 33259-2015 |

| UPT for eight GM-80 | Flange 250-16-01-1 GOST 33259-2015 |

Для просмотра полного описания технических характеристик отправьте заявку или войдите под своим профилем