WATER SPRAY SYSTEMS FOR LNG RESERVOIRS AND TANKS. FIRE PROTECTION FOR LIQUEFIED NATURAL GAS (LNG) STORAGES

Pozhneftehim supports designing fire protection systems and manufactures equipment for water spray systems of LNG facilities.

More than 10 year experience of reations with leading oil and gas and petrochemical organizations provides an opportunity to create highly effective fire protection systems.

LNG tanks. Photo: газэкосеть.рф

Choose water spray system or water curtain

Objects for storage and processing of liquefied natural gases (LNG). General information

Liquefied natural gas (LNG) is an odorless and colorless liquid with a density of 0.41-0.5 kg/l, depending on temperature, pressure and higher alkanes content.

The main substance in the LNG composition is methane, its content makes 85-95%.

Additional substances: ethane, propane, butane, nitrogen, hydrogen sulfide, mercaptan sulfur.

For comparison, liquefied hydrocarbon gases (LHG) contain the following main substances: propane and butane, their content is 95% min.

Additional substances: pentane, methane, ethane, ethylene, propylene, butylene.

Unlike LHG, which are stored in gasholders at a temperature close to atmospheric, LNG is stored in cryogenic tanks where a temperature of about minus 160оC is maintained.

Pure LNG does not burn, does not self-ignite or explode. In an open space at normal temperature, LNG returns to its gaseous state and mixes rapidly with air. During evaporation, natural gas can ignite if a contact with a flame source occurs.

According to SP 326.1311500.2017 “Objects of small-tonnage production and consumption of liquefied natural gas. Fire Safety Requirements”, LNG production facilities may include the following main systems, technological equipment, installations and structures:

- gas treatment unit, including cleaning and drying systems;

- natural gas (NG) compression unit;

- NG liquefaction plant;

- cryogenic reservoirs, etc.

According toSP 240.1311500.2015 “Storage of liquefied natural gas. Fire Safety Requirements” LNG storage facilities may include:

- insulated external metal walled tanks with a storage volume of up to 60,000 m3;

- isothermal external concrete walled tanks with a storage volume of up to 200,000 m3.

Key equipment for active fire protection of LNG facilities

In the event of a fire, extinguishing LNG is not advisable. In this case, it is necessary to protect the surrounding objects from the direct effects of the burning bed (thermal radiation, spread of combustion) by water spray.

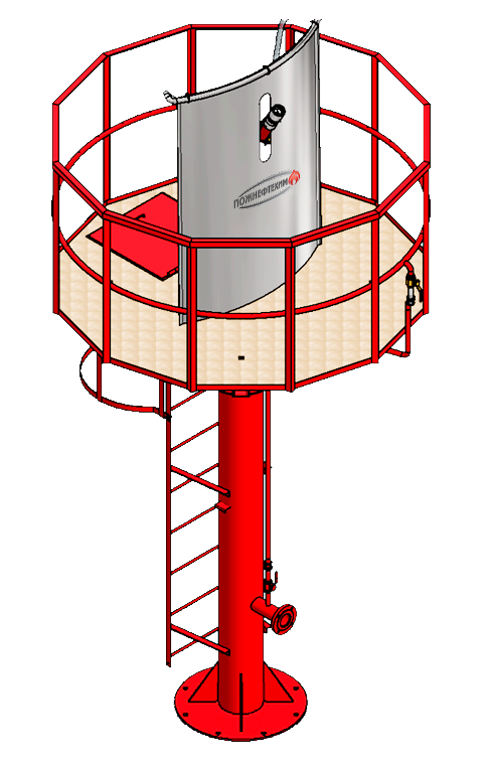

Therefore, the kye equipment providing active fire protection at consumption and production facilities includes fixed water spray installations and fire monitors. In some cases, water curtains are used.

Regulatory requirements for water spray of LNG tanks

According to SP 326.1311500.2017 “Objects of small-tonnage production and consumption of liquefied natural gas. Fire Safety Requirements":

- to protect against thermal effects during fires, LNG tanks, including tank of a mobile LNG bowser, must be protected by automatic water spray systems.

- buildings, rooms and structures of LNG production and consumption facilities subject to equipment with an automatic fire extinguishing installation, should be selected in accordance with the requirements of SP 5.13130.

According to SP 240.1311500.2015 “Storage of liquefied natural gas. Fire Safety Requirements":

- the need to equip buildings, structures, premises and equipment with an automatic fire extinguishing installation should be accepted, unless otherwise specified in this section, in accordance with paragraph 1.5 of Appendix A of SP 5.13130;

- fixed water spray installations (deluge installations) should be used to protect the walls, roof and platforms of manifolds and LNG transfer pumps. Fire monitors are allowed to cool pipelines and LNG fittings.

For more information on the Pozhneftehim water spray systems, see sections:

- Pozhneftehim manufactures deluge sprinklers for effective high water curtains

- Water spray systems for tanks and technological units, fixed water spray installations

IF YOU HAVE QUESTIONS OR PROPOSALS, PLEASE FILL IN OUR FORM

Filling out the form means you agree with the confidencial policy of the web-site www.pnx-spb.ru and agree to receive the email by Pozhneftehim-Expert to the indicated email. You can unsubscribe from the email at any time. You can also get access to emails that were send before. The contact email for the Pozhneftehim-Expert project is expert@pozhneftehim.ru.

PRODUCTION DIRECTIONS OF POZHNEFTEHIM-DETAL

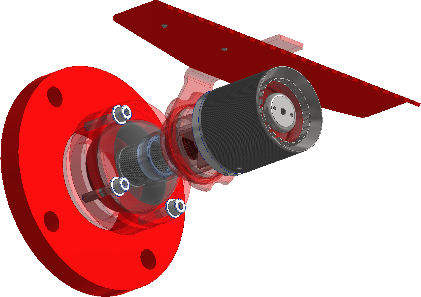

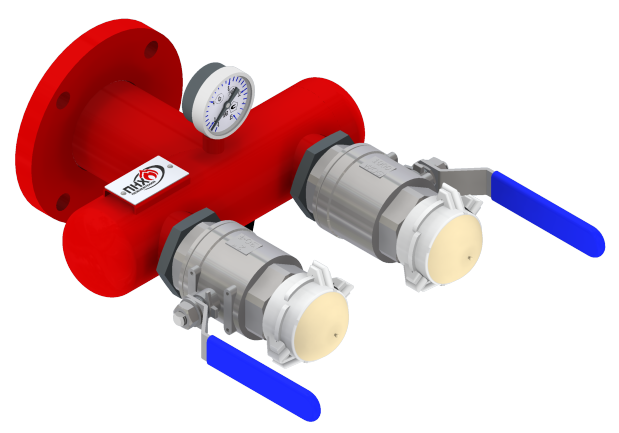

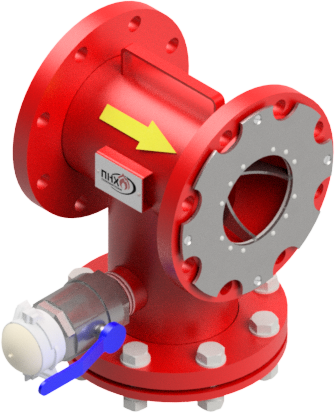

Pozhneftehim produces a wide range of equipment for fire extinguishing systems and installations. These are foam generators of low, medium, high expansion, fire filters, fire monitors, fire towers, stabilizers, interlayer nozzles, fire equipment connection nodes, etc.

Foam concentrate dosing systems with turbine inline, balanced pressure and foam inductor proportioners. Production of containers (tanks) for storage of foam concentrate and piping arrangement.

Pozhneftehim has been producing custom-made bladder tanks since 2010. We supply products with a full set of permits and operational documentation including factory test reports.

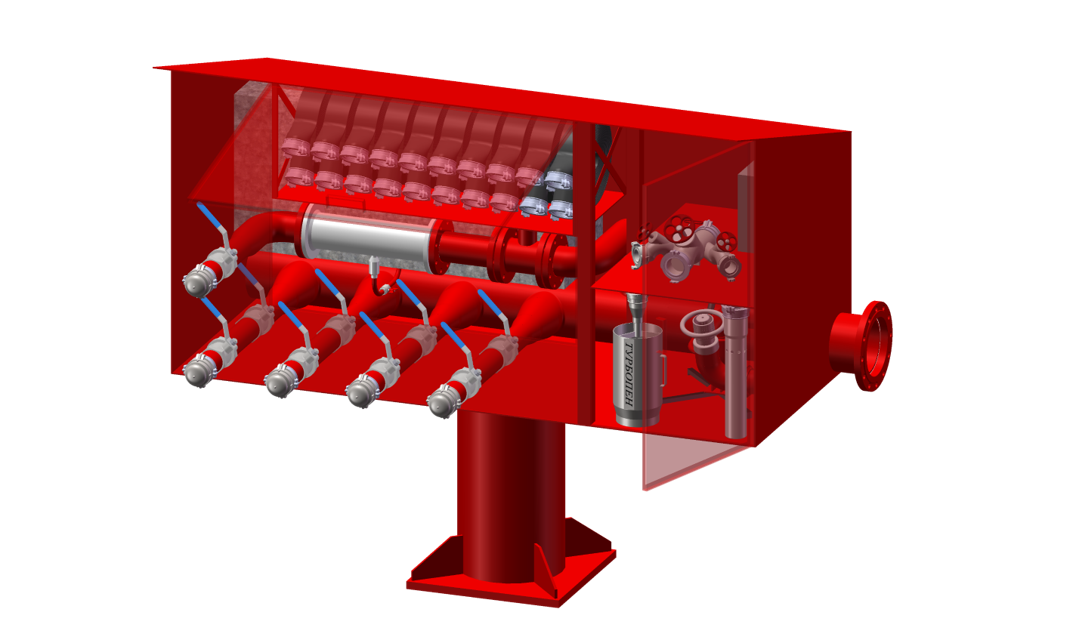

Custom-made block-modular structures: block containers, fire hydrant units, foam cabinets. Block-modular products of Pozhneftehim are equipped with equipment, systems and installations in accordance with the requirements of design documentation.