Materials of manufacture

In terms of resistance to climatic effects, the Antifire bladder tanks are manufactured in models U, HL, UHL, T, OM in accordance with GOST 15150-69.

Climatic model U, HL, UHL: material of piping and tank body - steel 09G2S with anti-corrosion coating;

Climatic model T, OM: material of piping and tank body - stainless steel.

Optionally, all types of climatic models of tanks, proportioners and piping can be made of stainless steel.

Key Specifications

Indicator name Indicator value

Design pressure, MPa 1,2 Operating pressure range, MPa 0,6–1,4 Nominal pressure, MPa 1,6 Design pressure, MPa, min 2,4 Operating temperature (without electric heating and insulation), ºС +5 ºС to +35 ºС Service life, years, min 10

Manufacture of customized Antifire bladder tank.2 •s-1 and dynamic viscosity, max 2,5 Pa•s.

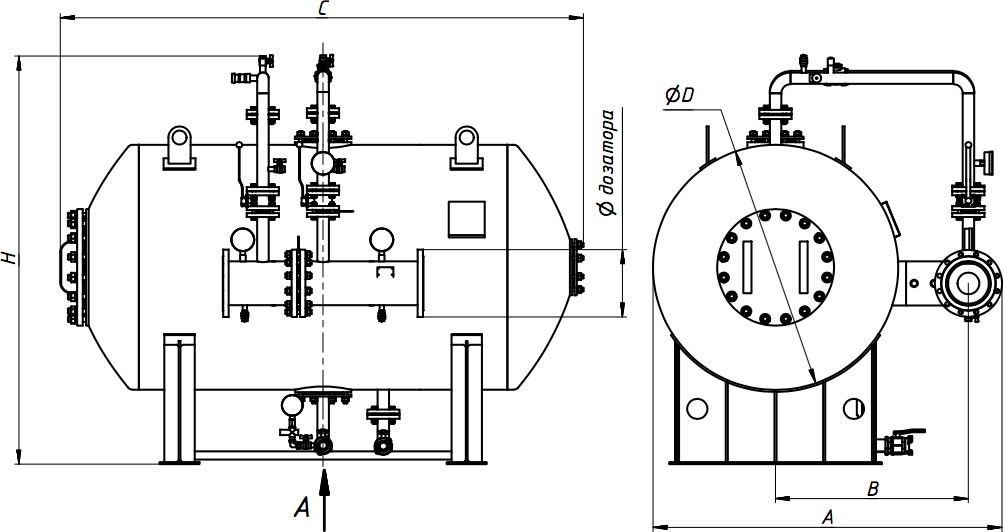

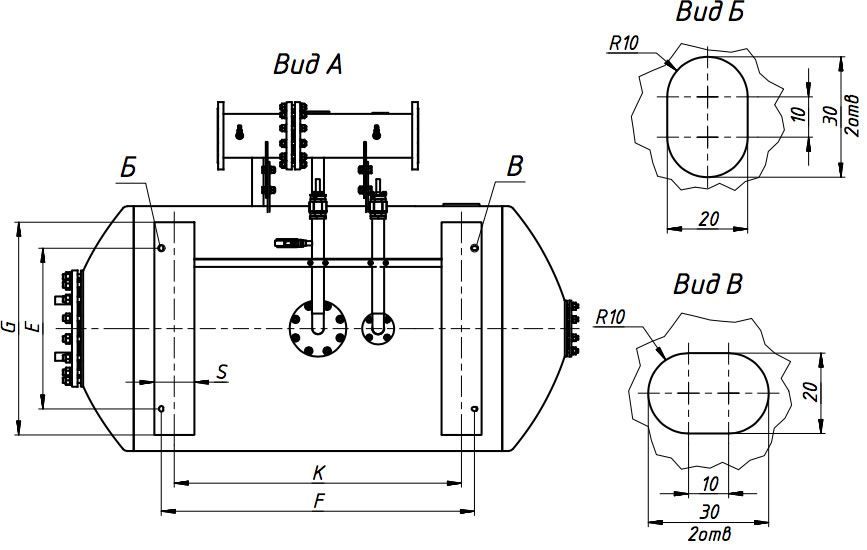

Overall dimensions and weight of the horizontal Antifire bladder tanks

Dimension Drawings Show

Select a proportioner:

---

Select a proportioner

3"

4"

6"

8"

10"

Tank with capacity, V, l :

---

600

1000

1500

2000

2500

3000

3500

4000

4500

5000

5500

6000

6500

7000

7500

8000

8500

9000

9500

10000

10500

11000

11500

12000

12500

13000

13500

14000

14500

15000

15500

16000

16500

17000

Tank with capacity, V, l

600

А, mm

1200

В, mm

700

М, kg

800

Н, mm

1400

С, mm

1500

D, mm

800

Е, mm

500

F, mm

800

G, mm

650

K, mm

700

S, mm

50

Tank with capacity, V, l

1000

А, mm

1350

В, mm

740

М, kg

920

Н, mm

1850

С, mm

1700

D, mm

1000

Е, mm

700

F, mm

800

G, mm

860

К, mm

740

S, mm

170

Tank with capacity, V, l

1500

А, mm

1350

В, mm

740

М, kg

1045

Н, mm

1850

С, mm

2200

D, mm

1000

Е, mm

700

F, mm

1290

G, mm

860

К, mm

1230

S, mm

190

Tank with capacity, V, l

2000

А, mm

1450

В, mm

790

М, kg

1225

Н, mm

1950

С, mm

2550

D, mm

1100

Е, mm

700

F, mm

1490

G, mm

960

К, mm

1400

S, mm

200

Tank with capacity, V, l

2500

А, mm

1560

В, mm

850

М, kg

1340

Н, mm

2050

С, mm

2700

D, mm

1200

Е, mm

700

F, mm

1520

G, mm

1060

К, mm

1430

S, mm

200

Tank with capacity, V, l

3000

А, mm

1730

В, mm

920

М, kg

1435

Н, mm

2250

С, mm

2450

D, mm

1400

Е, mm

700

F, mm

1270

G, mm

1260

К, mm

1180

S, mm

200

Tank with capacity, V, l

3500

А, mm

1730

В, mm

920

М, kg

1550

Н, mm

2250

С, mm

2800

D, mm

1400

Е, mm

700

F, mm

1590

G, mm

1260

К, mm

1500

S, mm

200

Tank with capacity, V, l

4000

А, mm

1730

В, mm

920

М, kg

1660

Н, mm

2250

С, mm

3100

D, mm

1400

Е, mm

700

F, mm

1590

G, mm

1260

К, mm

1500

S, mm

200

Tank with capacity, V, l

4500

А, mm

1900

В, mm

990

М, kg

1800

Н, mm

2500

С, mm

2850

D, mm

1600

Е, mm

1250

F, mm

1490

G, mm

1460

К, mm

1350

S, mm

250

Tank with capacity, V, l

5000

А, mm

1900

В, mm

990

М, kg

1900

Н, mm

2500

С, mm

3100

D, mm

1600

Е, mm

1250

F, mm

1640

G, mm

1460

К, mm

1500

S, mm

250

Tank with capacity, V, l

5500

А, mm

1900

В, mm

990

М, kg

1990

Н, mm

2500

С, mm

3300

D, mm

1600

Е, mm

1250

F, mm

1640

G, mm

1460

К, mm

1500

S, mm

250

Tank with capacity, V, l

6000

А, mm

2070

В, mm

1055

М, kg

2110

Н, mm

2700

С, мм

3050

D, mm

1800

Е, mm

1250

F, mm

1565

G, mm

1660

К, mm

1400

S, mm

280

Tank with capacity, V, l

6500

А, mm

2070

В, mm

1055

М, kg

2200

Н, mm

2700

С, mm

3250

D, mm

1800

Е, mm

1250

F, mm

1665

G, mm

1660

К, mm

1500

S, mm

280

Tank with capacity, V, l

7000

А, mm

2300

В, mm

1180

М, kg

2300

Н, mm

3100

С, mm

2900

D, mm

2000

Е, mm

1250

F, mm

1330

G, mm

1860

К, mm

1140

S, mm

300

Tank with capacity, V, l

7500

А, mm

2300

В, mm

1180

М, kg

2380

Н, mm

3100

С, mm

3050

D, mm

2000

Е, mm

1250

F, mm

1490

G, mm

1860

К, mm

1300

S, mm

300

Tank with capacity, V, l

8000

А, mm

2300

В, mm

1180

М, kg

2460

Н, mm

3100

С, mm

3200

D, mm

2000

Е, mm

1250

F, mm

1550

G, mm

1860

К, mm

1360

S, mm

300

Tank with capacity, V, l

8500

А, mm

2300

В, mm

1180

М, kg

2540

Н, mm

3100

С, mm

3300

D, mm

2000

Е, mm

1250

F, mm

1720

G, mm

1860

К, mm

1530

S, mm

300

Tank with capacity, V, l

9000

А, mm

2300

В, mm

1180

М, kg

2620

Н, mm

3100

С, mm

3500

D, mm

2000

Е, mm

1250

F, mm

1920

G, mm

1860

К, mm

1730

S, mm

300

Tank with capacity, V, l

9500

А, mm

2300

В, mm

1180

М, kg

2700

Н, mm

3100

С, mm

3700

D, mm

2000

Е, mm

1250

F, mm

1890

G, mm

1860

К, mm

1700

S, mm

300

Tank with capacity, V, l

10000

А, mm

2300

В, mm

1180

М, kg

2780

Н, mm

3100

С, mm

3850

D, mm

2000

Е, mm

1250

F, mm

2215

G, mm

1860

К, mm

2000

S, mm

300

Tank with capacity, V, l

10500

А, mm

2300

В, mm

1180

М, kg

2920

Н, mm

3100

С, mm

4000

D, mm

2000

Е, mm

1250

F, mm

2215

G, mm

1860

К, mm

2000

S, mm

310

Tank with capacity, V, l

11000

А, mm

2300

В, mm

1180

М, kg

3060

Н, mm

3100

С, mm

4150

D, mm

2000

Е, mm

1250

F, mm

2215

G, mm

1860

К, mm

2000

S, mm

310

Tank with capacity, V, l

11500

А, mm

2300

В, mm

1180

М, kg

3200

Н, mm

3100

С, mm

4300

D, mm

2000

Е, mm

1250

F, mm

2215

G, mm

1860

К, mm

2000

S, mm

310

Tank with capacity, V, l

12000

А, mm

2300

В, mm

1180

М, kg

3350

Н, mm

3100

С, mm

4500

D, mm

2000

Е, mm

1250

F, mm

2215

G, mm

1860

К, mm

2000

S, mm

310

Tank with capacity, V, l

12500

А, mm

2300

В, mm

1180

М, kg

3490

Н, mm

3100

С, mm

4650

D, mm

2000

Е, mm

1250

F, mm

2215

G, mm

1860

К, mm

2000

S, mm

310

Tank with capacity, V, l

13000

А, mm

2300

В, mm

1180

М, kg

3620

Н, mm

3100

С, mm

4800

D, mm

2000

Е, mm

1250

F, mm

2965

G, mm

1860

К, mm

2750

S, mm

350

Tank with capacity, V, l

13500

А, mm

2300

В, mm

1180

М, kg

3760

Н, mm

3100

С, mm

4950

D, mm

2000

Е, mm

1250

F, mm

3040

G, mm

1860

К, mm

2825

S, mm

350

Tank with capacity, V, l

14000

А, mm

2300

В, mm

1180

М, kg

3900

Н, mm

3100

С, mm

5100

D, mm

2000

Е, mm

1250

F, mm

3125

G, mm

1860

К, mm

2910

S, mm

350

Tank with capacity, V, l

14500

А, mm

2300

В, mm

1180

М, kg

4040

Н, mm

3100

С, mm

5250

D, mm

2000

Е, mm

1250

F, mm

3215

G, mm

1860

К, mm

3000

S, mm

350

Tank with capacity, V, l

15000

А, mm

2300

В, mm

1180

М, kg

4180

Н, mm

3100

С, mm

5400

D, mm

2000

Е, mm

1250

F, mm

3315

G, mm

1860

К, mm

3075

S, mm

350

Tank with capacity, V, l

15500

А, mm

2300

В, mm

1180

М, kg

4320

Н, mm

3100

С, mm

5550

D, mm

2000

Е, mm

1250

F, mm

3130

G, mm

1860

К, mm

2960

S, mm

350

Tank with capacity, V, l

16000

А, mm

2300

В, mm

1180

М, kg

4460

Н, mm

3100

С, mm

5700

D, mm

2000

Е, mm

1250

F, mm

3210

G, mm

1860

К, mm

3040

S, mm

350

Tank with capacity, V, l

16500

А, mm

2300

В, mm

1180

М, kg

4600

Н, mm

3100

С, mm

5850

D, mm

2000

Е, mm

1250

F, mm

3290

G, mm

1860

К, mm

3120

S, mm

350

Tank with capacity, V, l

17000

А, mm

2300

В, mm

1180

М, kg

4890

Н, mm

3100

С, mm

6100

D, mm

2000

Е, mm

1250

F, mm

3370

G, mm

1860

К, mm

3200

S, mm

350

Tank with capacity, V, l

600

1000

1500

2000

2500

3000

3500

4000

4500

5000

5500

6000

6500

7000

7500

8000

8500

9000

9500

10000

10500

11000

11500

12000

12500

13000

13500

14000

14500

15000

15500

16000

16500

17000

Tank with capacity, V, l Antifire bladder tank with 3” proportioner А, mm В, mm M, kg Н, mm С, mm D, mm Е, mm F, mm G, mm К, mm S, mm

600 1200 700 800 1400 1500 800 500 800 650 700 50

1000 1350 740 920 1850 1700 1000 700 800 860 740 170

1500 1350 740 1045 1850 2200 1000 700 1290 860 1230 190

2000 1450 790 1225 1950 2550 1100 700 1490 960 1400 200

2500 1560 850 1340 2050 2700 1200 700 1520 1060 1430 200

3000 1730 920 1435 2250 2450 1400 700 1270 1260 1180 200

3500 1730 920 1550 2250 2800 1400 700 1590 1260 1500 200

4000 1730 920 1660 2250 3100 1400 700 1590 1260 1500 200

4500 1900 990 1800 2500 2850 1600 1250 1490 1460 1350 250

5000 1900 990 1900 2500 3100 1600 1250 1640 1460 1500 250

5500 1900 990 1990 2500 3300 1600 1250 1640 1460 1500 250

6000 2070 1055 2110 2700 3050 1800 1250 1565 1660 1400 280

6500 2070 1055 2200 2700 3250 1800 1250 1665 1660 1500 280

7000 2300 1180 2300 3100 2900 2000 1250 1330 1860 1140 300

7500 2300 1180 2380 3100 3050 2000 1250 1490 1860 1300 300

8000 2300 1180 2460 3100 3200 2000 1250 1550 1860 1360 300

8500 2300 1180 2540 3100 3300 2000 1250 1720 1860 1530 300

9000 2300 1180 2620 3100 3500 2000 1250 1920 1860 1730 300

9500 2300 1180 2700 3100 3700 2000 1250 1890 1860 1700 300

10000 2300 1180 2780 3100 3850 2000 1250 2215 1860 2000 300

10500 2300 1180 2920 3100 4000 2000 1250 2215 1860 2000 310

11000 2300 1180 3060 3100 4150 2000 1250 2215 1860 2000 310

11500 2300 1180 3200 3100 4300 2000 1250 2215 1860 2000 310

12000 2300 1180 3350 3100 4500 2000 1250 2215 1860 2000 310

12500 2300 1180 3490 3100 4650 2000 1250 2215 1860 2000 310

13000 2300 1180 3620 3100 4800 2000 1250 2965 1860 2750 350

13500 2300 1180 3760 3100 4950 2000 1250 3040 1860 2825 350

14000 2300 1180 3900 3100 5100 2000 1250 3125 1860 2910 350

14500 2300 1180 4040 3100 5250 2000 1250 3215 1860 3000 350

15000 2300 1180 4180 3100 5400 2000 1250 3315 1860 3075 350

15500 2300 1180 4320 3100 5550 2000 1250 3130 1860 2960 350

16000 2300 1180 4460 3100 5700 2000 1250 3210 1860 3040 350

16500 2300 1180 4600 3100 5850 2000 1250 3290 1860 3120 350

17000 2300 1180 4890 3100 6100 2000 1250 3370 1860 3200 350

Select a proportioner:

---

600

1000

1500

2000

2500

3000

3500

4000

4500

5000

5500

6000

6500

7000

7500

8000

8500

9000

9500

10000

10500

11000

11500

12000

12500

13000

13500

14000

14500

15000

15500

16000

16500

17000

Tank with capacity, V, l

600

А, mm

1200

В, mm

700

М, kg

810

Н, mm

1400

С, mm

1500

D, mm

800

Е, mm

500

F, mm

800

G, mm

650

K, mm

700

S, mm

50

Tank with capacity, V, l

1000

А, mm

1360

В, mm

740

М, kg

930

Н, mm

1850

С, mm

1700

D, mm

1000

Е, mm

700

F, mm

800

G, mm

860

К, mm

740

S, mm

170

Tank with capacity, V, l

1500

А, mm

1360

В, mm

740

М, kg

1055

Н, mm

1850

С, mm

2200

D, mm

1000

Е, mm

700

F, mm

1290

G, mm

860

К, mm

1230

S, mm

190

Tank with capacity, V, l

2000

А, mm

1460

В, mm

790

М, kg

1235

Н, mm

1950

С, mm

2550

D, mm

1100

Е, mm

700

F, mm

1490

G, mm

960

К, mm

1400

S, mm

200

Tank with capacity, V, l

2500

А, mm

1570

В, mm

850

М, kg

1350

Н, mm

2050

С, mm

2700

D, mm

1200

Е, mm

700

F, mm

1520

G, mm

1060

К, mm

1430

S, mm

200

Tank with capacity, V, l

3000

А, mm

1720

В, mm

900

М, kg

1445

Н, mm

2250

С, mm

2450

D, mm

1400

Е, mm

700

F, mm

1270

G, mm

1260

К, mm

1180

S, mm

200

Tank with capacity, V, l

3500

А, mm

1720

В, mm

900

М, kg

1560

Н, mm

2250

С, mm

2800

D, mm

1400

Е, mm

700

F, mm

1590

G, mm

1260

К, mm

1500

S, mm

200

Tank with capacity, V, l

4000

А, mm

1720

В, mm

900

М, kg

1670

Н, mm

2250

С, mm

3100

D, mm

1400

Е, mm

700

F, mm

1590

G, mm

1260

К, mm

1500

S, mm

200

Tank with capacity, V, l

4500

А, mm

1920

В, mm

1000

М, kg

1810

Н, mm

2500

С, mm

2850

D, mm

1600

Е, mm

1250

F, mm

1490

G, mm

1460

К, mm

1350

S, mm

250

Tank with capacity, V, l

5000

А, mm

1920

В, mm

1000

М, kg

1910

Н, mm

2500

С, mm

3100

D, mm

1600

Е, mm

1250

F, mm

1640

G, mm

1460

К, mm

1500

S, mm

250

Tank with capacity, V, l

5500

А, mm

1920

В, mm

1000

М, kg

2000

Н, mm

2500

С, mm

3300

D, mm

1600

Е, mm

1250

F, mm

1640

G, mm

1460

К, mm

1500

S, mm

250

Tank with capacity, V, l

6000

А, mm

2120

В, mm

1100

М, kg

2120

Н, mm

2700

С, mm

3050

D, mm

1800

Е, mm

1250

F, mm

1565

G, mm

1660

К, mm

1400

S, mm

280

Tank with capacity, V, l

6500

А, mm

2120

В, mm

1100

М, kg

2210

Н, mm

2700

С, mm

3250

D, mm

1800

Е, mm

1250

F, mm

1665

G, mm

1660

К, mm

1500

S, mm

280

Tank with capacity, V, l

7000

А, mm

2320

В, mm

1180

М, kg

2310

Н, mm

3100

С, mm

2900

D, mm

2000

Е, mm

1250

F, mm

1330

G, mm

1860

К, mm

1140

S, mm

300

Tank with capacity, V, l

7500

А, mm

2320

В, mm

1180

М, kg

2390

Н, mm

3100

С, mm

3050

D, mm

2000

Е, mm

1250

F, mm

1490

G, mm

1860

К, mm

1300

S, mm

300

Tank with capacity, V, l

8000

А, mm

2320

В, mm

1180

М, kg

2470

Н, mm

3100

С, mm

3200

D, mm

2000

Е, mm

1250

F, mm

1550

G, mm

1860

К, mm

1360

S, mm

300

Tank with capacity, V, l

8500

А, mm

2320

В, mm

1180

М, kg

2550

Н, mm

3100

С, mm

3300

D, mm

2000

Е, mm

1250

F, mm

1720

G, mm

1860

К, mm

1530

S, mm

300

Tank with capacity, V, l

9000

А, mm

2320

В, mm

1180

М, kg

2630

Н, mm

3100

С, mm

3500

D, mm

2000

Е, mm

1250

F, mm

1920

G, mm

1860

К, mm

1730

S, mm

300

Tank with capacity, V, l

9500

А, mm

2320

В, mm

1180

М, kg

2710

Н, mm

3100

С, mm

3700

D, mm

2000

Е, mm

1250

F, mm

1890

G, mm

1860

К, mm

1700

S, mm

300

Tank with capacity, V, l

10000

А, mm

2320

В, mm

1180

М, kg

2790

Н, mm

3100

С, mm

3850

D, mm

2000

Е, mm

1250

F, mm

2215

G, mm

1860

К, mm

2000

S, mm

300

Tank with capacity, V, l

10500

А, mm

2320

В, mm

1180

М, kg

2930

Н, mm

3100

С, mm

4000

D, mm

2000

Е, mm

1250

F, mm

2215

G, mm

1860

К, mm

2000

S, mm

310

Tank with capacity, V, l

11000

А, mm

2320

В, mm

1180

М, kg

3070

Н, mm

3100

С, mm

4150

D, mm

2000

Е, mm

1250

F, mm

2215

G, mm

1860

К, mm/p>

2000

S, mm

310

Tank with capacity, V, l

11500

А, mm

2320

В, mm

1180

М, kg

3210

Н, mm

3100

С, mm

4300

D, mm

2000

Е, mm

1250

F, mm

2215

G, mm

1860

К, mm

2000

S, mm

310

Tank with capacity, V, l

12000

А, mm

2320

В, mm

1180

М, kg

3360

Н, mm

3100

С, mm

4500

D, mm

2000

Е, mm

1250

F, mm

2215

G, mm

1860

К, mm

2000

S, mm

310

Tank with capacity, V, l

12500

А, mm

2320

В, mm

1180

М, kg

3500

Н, mm

3100

С, mm

4650

D, mm

2000

Е, mm

1250

F, mm

2215

G, mm

1860

К, mm

2000

S, mm

310

Tank with capacity, V, l

13000

А, mm

2320

В, mm

1180

М, kg

3630

Н, mm

3100

С, mm

4800

D, mm

2000

Е, mm

1250

F, mm

2965

G, mm

1860

К, mm

2750

S, mm

350

Tank with capacity, V, l

13500

А, mm

2320

В, mm

1180

М, kg

3770

Н, mm

3100

С, mm

4950

D, mm

2000

Е, mm

1250

F, mm

3040

G, mm

1860

К, mm

2825

S, mm

350

Tank with capacity, V, l

14000

А, mm

2320

В, mm

1180

М, kg

3910

Н, mm

3100

С, mm

5100

D, mm

2000

Е, mm

1250

F, mm

3125

G, mm

1860

К, mm

2910

S, mm

350

Tank with capacity, V, l

14500

А, mm

2320

В, mm

1180

М, kg

4050

Н, mm

3100

С, mm

5250

D, mm

2000

Е, mm

1250

F, mm

3215

G, mm

1860

К, mm

3000

S, mm

350

Tank with capacity, V, l

15000

А, mm

2320

В, mm

1180

М, kg

4190

Н, mm

3100

С,mm

5400

D, mm

2000

Е, mm

1250

F, mm

3315

G, mm

1860

К, mm

3075

S, mm

350

Tank with capacity, V, l

15500

А, mm

2320

В, mm

1180

М, kg

4330

Н, mm

3100

С, mm

5550

D, mm

2000

Е, mm

1250

F, mm

3130

G, mm

1860

К, mm

2960

S, mm

350

Tank with capacity, V, l

16000

А, mm

2320

В, mm

1180

М, kg

4470

Н, mm

3100

С, mm

5700

D, mm

2000

Е, mm

1250

F, mm

3210

G, mm

1860

К, mm

3040

S, mm

350

Tank with capacity, V, l

16500

А, mm

2320

В, mm

1180

М, kg

4610

Н, mm

3100

С, mm

5850

D, mm

2000

Е, mm

1250

F, mm

3290

G, mm

1860

К, mm

3120

S, mm

350

Tank with capacity, V, l

17000

А, mm

2320

В, mm

1180

М, kg

4900

Н, mm

3100

С, mm

6100

D, mm

2000

Е, mm

1250

F, mm

3370

G, mm

1860

К, mm

3200

S, mm

350

Tank with capacity, V, l

600

1000

1500

2000

2500

3000

3500

4000

4500

5000

5500

6000

6500

7000

7500

8000

8500

9000

9500

10000

10500

11000

11500

12000

12500

13000

13500

14000

14500

15000

15500

16000

16500

17000

Tank with capacity, V, l Antifire bladder tank with 4” proportioner А, mm В, mm М, kg Н, mm С, mm D, mm Е, mm F, mm G, mm К, mm S, mm

600 1200 700 810 1400 1500 800 500 800 650 700 50

1000 1360 740 930 1850 1700 1000 700 800 860 740 170

1500 1360 740 1055 1850 2200 1000 700 1290 860 1230 190

2000 1460 790 1235 1950 2550 1100 700 1490 960 1400 200

2500 1570 850 1350 2050 2700 1200 700 1520 1060 1430 200

3000 1720 900 1445 2250 2450 1400 700 1270 1260 1180 200

3500 1720 900 1560 2250 2800 1400 700 1590 1260 1500 200

4000 1720 900 1670 2250 3100 1400 700 1590 1260 1500 200

4500 1920 1000 1810 2500 2850 1600 1250 1490 1460 1350 250

5000 1920 1000 1910 2500 3100 1600 1250 1640 1460 1500 250

5500 1920 1000 2000 2500 3300 1600 1250 1640 1460 1500 250

6000 2120 1100 2120 2700 3050 1800 1250 1565 1660 1400 280

6500 2120 1100 2210 2700 3250 1800 1250 1665 1660 1500 280

7000 2320 1180 2310 3100 2900 2000 1250 1330 1860 1140 300

7500 2320 1180 2390 3100 3050 2000 1250 1490 1860 1300 300

8000 2320 1180 2470 3100 3200 2000 1250 1550 1860 1360 300

8500 2320 1180 2550 3100 3300 2000 1250 1720 1860 1530 300

9000 2320 1180 2630 3100 3500 2000 1250 1920 1860 1730 300

9500 2320 1180 2710 3100 3700 2000 1250 1890 1860 1700 300

10000 2320 1180 2790 3100 3850 2000 1250 2215 1860 2000 300

10500 2320 1180 2930 3100 4000 2000 1250 2215 1860 2000 310

11000 2320 1180 3070 3100 4150 2000 1250 2215 1860 2000 310

11500 2320 1180 3210 3100 4300 2000 1250 2215 1860 2000 310

12000 2320 1180 3360 3100 4500 2000 1250 2215 1860 2000 310

12500 2320 1180 3500 3100 4650 2000 1250 2215 1860 2000 310

13000 2320 1180 3630 3100 4800 2000 1250 2965 1860 2750 350

13500 2320 1180 3770 3100 4950 2000 1250 3040 1860 2825 350

14000 2320 1180 3910 3100 5100 2000 1250 3125 1860 2910 350

14500 2320 1180 4050 3100 5250 2000 1250 3215 1860 3000 350

15000 2320 1180 4190 3100 5400 2000 1250 3315 1860 3075 350

15500 2320 1180 4330 3100 5550 2000 1250 3130 1860 2960 350

16000 2320 1180 4470 3100 5700 2000 1250 3210 1860 3040 350

16500 2320 1180 4610 3100 5850 2000 1250 3290 1860 3120 350

17000 2320 1180 4900 3100 6100 2000 1250 3370 1860 3200 350

Select a proportioner:

---

600

1000

1500

2000

2500

3000

3500

4000

4500

5000

5500

6000

6500

7000

7500

8000

8500

9000

9500

10000

10500

11000

11500

12000

12500

13000

13500

14000

14500

15000

15500

16000

16500

17000

Tank with capacity, V, l

600

А, mm

1250

В, mm

750

М, kg

840

Н, mm

1400

С, mm

1500

D, mm

800

Е, mm

500

F, mm

800

G, mm

650

K, mm

700

S, mm

50

Tank with capacity, V, l

1000

А, mm

1450

В, mm

800

М, kg

960

Н, mm

1850

С, mm

1700

D, mm

1000

Е, mm

700

F, mm

800

G, mm

860

К, mm

740

S, mm

170

Tank with capacity, V, l

1500

А, mm

1450

В, mm

800

М, kg

1080

Н, mm

1850

С, mm

2200

D, mm

1000

Е, mm

700

F, mm

1290

G, mm

860

К, mm

1230

S, mm

190

Tank with capacity, V, l

2000

А, mm

1560

В, mm

860

М, kg

1260

Н, mm

1950

С, mm

2550

D, mm

1100

Е, mm

700

F, mm

1490

G, mm

960

К, mm

1400

S, mm

200

Tank with capacity, V, l

2500

А, mm

1650

В, mm

900

М, kg

1375

Н, mm

2050

С, mm

2700

D, mm

1200

Е, mm

700

F, mm

1520

G, mm

1060

К, mm

1430

S, mm

200

Tank with capacity, V, l

3000

А, mm

1830

В, mm

980

М, kg

1470

Н, mm

2250

С, mm

2450

D, mm

1400

Е, mm

700

F, mm

1270

G, mm

1260

К, mm

1180

S, mm

200

Tank with capacity, V, l

3500

А, mm

1830

В, mm

980

М, kg

1585

Н, mm

2250

С, mm

2800

D, mm

1400

Е, mm

700

F, mm

1590

G, mm

1260

К, mm

1500

S, mm

200

Tank with capacity, V, l

4000

А, mm

1830

В, mm

980

М, kg

1700

Н, mm

2250

С, mm

3100

D, mm

1400

Е, mm

700

F, mm

1590

G, mm

1260

К, mm

1500

S, mm

200

Tank with capacity, V, l

4500

А, mm

2030

В, mm

1075

М, kg

1835

Н, mm

2500

С, mm

2850

D, mm

1600

Е, mm

1250

F, mm

1490

G, mm

1460

К, mm

1350

S, mm

250

Tank with capacity, V, l

5000

А, mm

2030

В, mm

1075

М, kg

1930

Н, mm

2500

С, mm

3100

D, mm

1600

Е, mm

1250

F, mm

1640

G, mm

1460

К, mm

1500

S, mm

250

Tank with capacity, V, l

5500

А, mm

2030

В, mm

1075

М, kg

2025

Н, mm

2500

С, mm

3300

D, mm

1600

Е, mm

1250

F, mm

1640

G, mm

1460

К, mm

1500

S, mm

250

Tank with capacity, V, l

6000

А, mm

2200

В, mm

1150

М, kg

2145

Н, mm

2700

С, mm

3050

D, mm

1800

Е, mm

1250

F, mm

1565

G, mm

1660

К, mm

1400

S, mm

280

Tank with capacity, V, l

6500

А, mm

2200

В, mm

1150

М, kg

2235

Н, mm

2700

С, mm

3250

D, mm

1800

Е, mm

1250

F, mm

1665

G, mm

1660

К, mm

1500

S, mm

280

Tank with capacity, V, l

7000

А, mm

2360

В, mm

1210

М, kg

2335

Н, mm

3100

С, mm

2900

D, mm

2000

Е, mm

1250

F, mm

1330

G, mm

1860

К, mm

1140

S, mm

300

Tank with capacity, V, l

7500

А, mm

2360

В, mm

1210

М, kg

2415

Н, mm

3100

С, mm

3050

D, mm

2000

Е, mm

1250

F, mm

1490

G, mm

1860

К, mm

1300

S, мм

300

Tank with capacity, V, l

8000

А, mm

2360

В, mm

1210

М, kg

2500

Н, mm

3100

С, mm

3200

D, mm

2000

Е, mm

1250

F, mm

1550

G, mm

1860

К, mm

1360

S, mm

300

Tank with capacity, V, l

8500

А, mm

2360

В, mm

1210

М, kg

2580

Н, mm

3100

С, mm

3300

D, mm

2000

Е, mm

1250

F, mm

1720

G, mm

1860

К, mm

1530

S, mm

300

Tank with capacity, V, l

9000

А, mm

2360

В, mm

1210

М, kg

2660

Н, mm

3100

С, mm

3500

D, mm

2000

Е, mm

1250

F, mm

1920

G, mm

1860

К, mm

1730

S,mm

300

Tank with capacity, V, l

9500

А, mm

2360

В, mm

1210

М, kg

2740

Н, mm

3100

С, mm

3700

D, mm

2000

Е, mm

1250

F, mm

1890

G, mm

1860

К, mm

1700

S, mm

300

Tank with capacity, V, l

10000

А, mm

2360

В, mm

1210

М, kg

2820

Н, mm

3100

С, mm

3850

D, mm

2000

Е, mm

1250

F, mm

2215

G, mm

1860

К, mm

2000

S, mm

300

Tank with capacity, V, l

10500

А, mm

2360

В, mm

1210

М, kg

2960

Н, mm

3100

С, mm

4000

D, mm

2000

Е, mm

1250

F, mm

2215

G, mm

1860

К, mm

2000

S, mm

310

Tank with capacity, V, l

11000

А, mm

2360

В, mm

1210

М, kg

3100

Н, mm

3100

С, mm

4150

D, mm

2000

Е, mm

1250

F, mm

2215

G, mm

1860

К, mm

2000

S, mm

310

Tank with capacity, V, l

11500

А, mm

2360

В, mm

1210

М, kg

3240

Н, mm

3100

С, mm

4300

D, mm

2000

Е, mm

1250

F, mm

2215

G, mm

1860

К, mm

2000

S, mm

310

Tank with capacity, V, l

12000

А, mm

2360

В, mm

1210

М, kg

3380

Н, mm

3100

С, mm

4500

D, mm

2000

Е, mm

1250

F, mm

2215

G, mm

1860

К, mm

2000

S, mm

310

Tank with capacity, V, l

12500

А, mm

2360

В, mm

1210

М, kg

3520

Н, mm

3100

С, mm

4650

D, mm

2000

Е, mm

1250

F, mm

2215

G, mm

1860

К, mm

2000

S, mm

310

Tank with capacity, V, l

13000

А, mm

2360

В, mm

1210

М, kg

3660

Н, mm

3100

С, mm

4800

D, mm

2000

Е, mm

1250

F, mm

2965

G, mm

1860

К, mm

2750

S, mm

350

Tank with capacity, V, l

13500

А, mm

2360

В, mm

1210

М, kg

3800

Н, mm

3100

С, mm

4950

D, mm

2000

Е, mm

1250

F, mm

3040

G, mm

1860

К, mm

2825

S, mm

350

Tank with capacity, V, l

14000

А, mm

2360

В, mm

1210

М, kg

3940

Н, mm

3100

С, mm

5100

D, mm

2000

Е, mm

1250

F, mm

3125

G, mm

1860

К, mm

2910

S, mm

350

Tank with capacity, V, l

14500

А, mm

2360

В, mm

1210

М, kg

4080

Н, mm

3100

С, mm

5250

D, mm

2000

Е, mm

1250

F, mm

3215

G, mm

1860

К, mm

3000

S, mm

350

Tank with capacity, V, l

15000

А, mm

2360

В, mm

1210

М, kg

4220

Н, mm

3100

С, mm

5400

D, mm

2000

Е, mm

1250

F, mm

3315

G, mm

1860

К, mm

3075

S, mm

350

Tank with capacity, V, l

15500

А, mm

2360

В, mm

1210

М, kg

4360

Н, mm

3100

С, mm

5550

D, mm

2000

Е, mm

1250

F, mm

3130

G, mm

1860

К, mm

2960

S, mm

350

Tank with capacity, V, l

16000

А, mm

2360

В, mm

1210

М, kg

4500

Н, mm

3100

С, мм

5700

D, mm

2000

Е, mm

1250

F, mm

3210

G, mm

1860

К, mm

3040

S, mm

350

Tank with capacity, V, l

16500

А, mm

2360

В, mm

1210

М, kg

4640

Н, mm

3100

С, mm

5850

D, mm

2000

Е, mm

1250

F, mm

3290

G, mm

1860

К, mm

3120

S, mm

350

Tank with capacity, V, l

17000

А, mm

2360

В, mm

1210

М, kg

4930

Н, mm

3100

С, mm

6100

D, mm

2000

Е, mm

1250

F, mm

3370

G, mm

1860

К, mm

3200

S, mm

350

Tank with capacity, V, l

600

1000

1500

2000

2500

3000

3500

4000

4500

5000

5500

6000

6500

7000

7500

8000

8500

9000

9500

10000

10500

11000

11500

12000

12500

13000

13500

14000

14500

15000

15500

16000

16500

17000

Tank with capacity, V, l БД «Антифайер» с дозирующим устройством 6” А, mm В, mm M, kg Н, mm С, mm D, mm Е, mm F, mm G, mm К, mm S, mm

600 1250 750 840 1400 1500 800 500 800 650 700 50

1000 1450 800 960 1850 1700 1000 700 800 860 740 170

1500 1450 800 1080 1850 2200 1000 700 1290 860 1230 190

2000 1560 860 1260 1950 2550 1100 700 1490 960 1400 200

2500 1650 900 1375 2050 2700 1200 700 1520 1060 1430 200

3000 1830 980 1470 2250 2450 1400 700 1270 1260 1180 200

3500 1830 980 1585 2250 2800 1400 700 1590 1260 1500 200

4000 1830 980 1700 2250 3100 1400 700 1590 1260 1500 200

4500 2030 1075 1835 2500 2850 1600 1250 1490 1460 1350 250

5000 2030 1075 1930 2500 3100 1600 1250 1640 1460 1500 250

5500 2030 1075 2025 2500 3300 1600 1250 1640 1460 1500 250

6000 2200 1150 2145 2700 3050 1800 1250 1565 1660 1400 280

6500 2200 1150 2235 2700 3250 1800 1250 1665 1660 1500 280

7000 2360 1210 2335 3100 2900 2000 1250 1330 1860 1140 300

7500 2360 1210 2415 3100 3050 2000 1250 1490 1860 1300 300

8000 2360 1210 2500 3100 3200 2000 1250 1550 1860 1360 300

8500 2360 1210 2580 3100 3300 2000 1250 1720 1860 1530 300

9000 2360 1210 2660 3100 3500 2000 1250 1920 1860 1730 300

9500 2360 1210 2740 3100 3700 2000 1250 1890 1860 1700 300

10000 2360 1210 2820 3100 3850 2000 1250 2215 1860 2000 300

10500 2360 1210 2960 3100 4000 2000 1250 2215 1860 2000 310

11000 2360 1210 3100 3100 4150 2000 1250 2215 1860 2000 310

11500 2360 1210 3240 3100 4300 2000 1250 2215 1860 2000 310

12000 2360 1210 3380 3100 4500 2000 1250 2215 1860 2000 310

12500 2360 1210 3520 3100 4650 2000 1250 2215 1860 2000 310

13000 2360 1210 3660 3100 4800 2000 1250 2965 1860 2750 350

13500 2360 1210 3800 3100 4950 2000 1250 3040 1860 2825 350

14000 2360 1210 3940 3100 5100 2000 1250 3125 1860 2910 350

14500 2360 1210 4080 3100 5250 2000 1250 3215 1860 3000 350

15000 2360 1210 4220 3100 5400 2000 1250 3315 1860 3075 350

15500 2360 1210 4360 3100 5550 2000 1250 3130 1860 2960 350

16000 2360 1210 4500 3100 5700 2000 1250 3210 1860 3040 350

16500 2360 1210 4640 3100 5850 2000 1250 3290 1860 3120 350

17000 2360 1210 4930 3100 6100 2000 1250 3370 1860 3200 350

Select a proportioner:

---

1000

1500

2000

2500

3000

3500

4000

4500

5000

5500

6000

6500

7000

7500

8000

8500

9000

9500

10000

10500

11000

11500

12000

12500

13000

13500

14000

14500

15000

15500

16000

16500

17000

Tank with capacity, V, l

1000

А, mm

1540

В, mm

860

М, kg

980

Н, mm

1850

С, mm

1700

D, mm

1000

Е, mm

700

F, mm

800

G, mm

860

К, mm

740

S, mm

170

Tank with capacity, V, l

1500

А, mm

1540

В, mm

860

М, kg

1100

Н, mm

1850

С, mm

2200

D, mm

1000

Е, mm

700

F, mm

1290

G, mm

860

К, mm

1230

S, mm

190

Tank with capacity, V, l

2000

А, mm

1640

В, mm

910

М, kg

1285

Н, mm

1950

С, mm

2550

D, mm

1100

Е, mm

700

F, mm

1490

G, mm

960

К, mm

1400

S, mm

200

Tank with capacity, V, l

2500

А, mm

1750

В, mm

960

М, kg

1400

Н, mm

2050

С, mm

2700

D, mm

1200

Е, mm

700

F, мм

1520

G, mm

1060

К, mm

1430

S, mm

200

Tank with capacity, V, l

3000

А, mm

1930

В, mm

1050

М, kg

1500

Н, mm

2250

С, mm

2450

D, mm

1400

Е, mm

700

F, mm

1270

G, mm

1260

К, mm

1180

S, mm

200

Tank with capacity, V, l

3500

А, mm

1930

В, mm

1050

М, kg

1610

Н, mm

2250

С, mm

2800

D, mm

1400

Е, mm

700

F, mm

1590

G, mm

1260

К, mm

1500

S, mm

200

Tank with capacity, V, l

4000

А, mm

1930

В, mm

1050

М, kg

1720

Н, mm

2250

С, mm

3100

D, mm

1400

Е, mm

700

F, mm

1590

G, mm

1260

К, mm

1500

S, mm

200

Tank with capacity, V, l

4500

А, mm

2110

В, mm

1130

М, kg

1860

Н, mm

2500

С, mm

2850

D, mm

1600

Е, mm

1250

F, mm

1490

G, mm

1460

К, mm

1350

S, мм

250

Tank with capacity, V, l

5000

А, mm

2110

В, mm

1130

М, kg

1960

Н, mm

2500

С, mm

3100

D, mm

1600

Е, mm

1250

F, mm

1640

G, mm

1460

К, mm

1500

S, mm

250

Tank with capacity, V, l

5500

А, mm

2110

В, mm

1130

М, kg

2050

Н, mm

2500

С, mm

3300

D, mm

1600

Е, mm

1250

F, mm

1640

G, mm

1460

К, mm

1500

S, mm

250

Tank with capacity, V, l

6000

А, mm

2290

В, mm

1210

М, kg

2170

Н, mm

2700

С, mm

3050

D, mm

1800

Е, mm

1250

F, mm

1565

G, mm

1660

К, mm

1400

S, mm

280

Tank with capacity, V, l

6500

А, mm

2290

В, mm

1210

М, kg

2260

Н, mm

2700

С, mm

3250

D, mm

1800

Е, mm

1250

F, mm

1665

G, mm

1660

К, mm

1500

S, mm

280

Tank with capacity, V, l

7000

А, mm

2430

В, mm

1250

М, kg

2360

Н, mm

3100

С, mm

2900

D, mm

2000

Е, mm

1250

F, mm

1330

G, mm

1860

К, mm

1140

S, mm

300

Tank with capacity, V, l

7500

А, mm

2430

В, mm

1250

М, kg

2440

Н, mm

3100

С, mm

3050

D, mm

2000

Е, mm

1250

F, mm

1490

G, mm

1860

К, mm

1300

S, mm

300

Tank with capacity, V, l

8000

А, mm

2430

В, mm

1250

М, kg

2520

Н, mm

3100

С, mm

3200

D, mm

2000

Е, mm

1250

F, mm

1550

G, mm

1860

К, mm

1360

S, mm

300

Tank with capacity, V, l

8500

А, mm

2430

В, mm

1250

М, kg

2600

Н, mm

3100

С, mm

3300

D, mm

2000

Е, mm

1250

F, mm

1720

G, mm

1860

К, mm

1530

S, mm

300

Tank with capacity, V, l

9000

А, mm

2430

В, mm

1250

М, kg

2680

Н, mm

3100

С, mm

3500

D, mm

2000

Е, mm

1250

F, mm

1920

G, mm

1860

К, mm

1730

S, mm

300

Tank with capacity, V, l

9500

А, mm

2430

В, mm

1250

М, kg

2760

Н, mm

3100

С, mm

3700

D, mm

2000

Е, mm

1250

F, mm

1890

G, mm

1860

К, mm

1700

S, mm

300

Tank with capacity, V, l

10000

А, mm

2430

В, mm

1250

М, kg

2840

Н, mm

3100

С, mm

3850

D, mm

2000

Е, mm

1250

F, mm

2215

G, mm

1860

К, mm

2000

S, mm

300

Tank with capacity, V, l

10500

А, mm

2430

В, mm

1250

М, kg

2980

Н, mm

3100

С, mm

4000

D, mm

2000

Е, mm

1250

F, mm

2215

G, mm

1860

К, mm

2000

S, mm

310

Tank with capacity, V, l

11000

А, mm

2430

В, mm

1250

М, kg

3120

Н, mm

3100

С, mm

4150

D, mm

2000

Е, mm

1250

F, mm

2215

G, mm

1860

К, mm

2000

S, mm

310

Tank with capacity, V, l

11500

А, mm

2430

В, mm

1250

М, kg

3260

Н, mm

3100

С, mm

4300

D, mm

2000

Е, mm

1250

F, mm

2215

G, mm

1860

К, mm

2000

S, mm

310

Tank with capacity, V, l

12000

А, mm

2430

В, mm

1250

М, kg

3400

Н, mm

3100

С, mm

4500

D, mm

2000

Е, mm

1250

F, mm

2215

G, mm

1860

К, mm

2000

S, mm

310

Tank with capacity, V, l

12500

А, mm

2430

В, mm

1250

М, kg

3540

Н, mm

3100

С, mm

4650

D, mm

2000

Е, mm

1250

F, mm

2215

G, mm

1860

К, mm

2000

S, mm

310

Tank with capacity, V, l

13000

А, mm

2430

В, mm

1250

М, kg

3680

Н, mm

3100

С, mm

4800

D, mm

2000

Е, mm

1250

F, mm

2965

G, mm

1860

К, mm

2750

S, mm

350

Tank with capacity, V, l

13500

А, mm

2430

В, mm

1250

М, kg

3820

Н, mm

3100

С, mm

4950

D, mm

2000

Е, mm

1250

F, mm

3040

G, mm

1860

К, mm

2825

S, mm

350

Tank with capacity, V, l

14000

А, mm

2430

В, mm

1250

М, kg

3960

Н, mm

3100

С, mm

5100

D, mm

2000

Е, mm

1250

F, mm

3125

G, mm

1860

К, mm

2910

S, mm

350

Tank with capacity, V, l

14500

А, mm

2430

В, mm

1250

М, kg

4100

Н, mm

3100

С, mm

5250

D, mm

2000

Е, mm

1250

F, mm

3215

G, mm

1860

К, mm

3000

S, mm

350

Tank with capacity, V, l

15000

А, mm

2430

В, mm

1250

М, kg

4240

Н, mm

3100

С, mm

5400

D, mm

2000

Е, mm

1250

F, mm

3315

G, mm

1860

К, mm

3075

S, mm

350

Tank with capacity, V, l

15500

А, mm

2430

В, mm

1250

М, kg

4380

Н, mm

3100

С, mm

5550

D, mm

2000

Е, mm

1250

F, mm

3130

G, mm

1860

К, mm

2960

S, mm

350

Tank with capacity, V, l

16000

А, mm

2430

В, mm

1250

М, kg

4520

Н, mm

3100

С, mm

5700

D, mm

2000

Е, mm

1250

F, mm

3210

G, mm

1860

К, mm

3040

S, mm

350

Tank with capacity, V, l

16500

А, mm

2430

В, mm

1250

М, kg

4660

Н, mm

3100

С, mm

5850

D, mm

2000

Е, mm

1250

F, mm

3290

G, mm

1860

К, mm

3120

S, mm

350

Tank with capacity, V, l

17000

А, mm

2430

В, mm

1250

М, kg

4950

Н, mm

3100

С, mm

6100

D, mm

2000

Е, mm

1250

F, mm

3370

G, mm

1860

К, mm

3200

S, mm

350

Tank with capacity, V, l

1000

1500

2000

2500

3000

3500

4000

4500

5000

5500

6000

6500

7000

7500

8000

8500

9000

9500

10000

10500

11000

11500

12000

12500

13000

13500

14000

14500

15000

15500

16000

16500

17000

Tank with capacity, V, l Antifire bladder tank with 8” proportioner А, mm В, mm M, KG Н, mm С, mm D, mm Е, mm F, mm G, mm К, mm S, mm

1000 1540 860 980 1850 1700 1000 700 800 860 740 170

1500 1540 860 1100 1850 2200 1000 700 1290 860 1230 190

2000 1640 910 1285 1950 2550 1100 700 1490 960 1400 200

2500 1750 960 1400 2050 2700 1200 700 1520 1060 1430 200

3000 1930 1050 1500 2250 2450 1400 700 1270 1260 1180 200

3500 1930 1050 1610 2250 2800 1400 700 1590 1260 1500 200

4000 1930 1050 1720 2250 3100 1400 700 1590 1260 1500 200

4500 2110 1130 1860 2500 2850 1600 1250 1490 1460 1350 250

5000 2110 1130 1960 2500 3100 1600 1250 1640 1460 1500 250

5500 2110 1130 2050 2500 3300 1600 1250 1640 1460 1500 250

6000 2290 1210 2170 2700 3050 1800 1250 1565 1660 1400 280

6500 2290 1210 2260 2700 3250 1800 1250 1665 1660 1500 280

7000 2430 1250 2360 3100 2900 2000 1250 1330 1860 1140 300

7500 2430 1250 2440 3100 3050 2000 1250 1490 1860 1300 300

8000 2430 1250 2520 3100 3200 2000 1250 1550 1860 1360 300

8500 2430 1250 2600 3100 3300 2000 1250 1720 1860 1530 300

9000 2430 1250 2680 3100 3500 2000 1250 1920 1860 1730 300

9500 2430 1250 2760 3100 3700 2000 1250 1890 1860 1700 300

10000 2430 1250 2840 3100 3850 2000 1250 2215 1860 2000 300

10500 2430 1250 2980 3100 4000 2000 1250 2215 1860 2000 310

11000 2430 1250 3120 3100 4150 2000 1250 2215 1860 2000 310

11500 2430 1250 3260 3100 4300 2000 1250 2215 1860 2000 310

12000 2430 1250 3400 3100 4500 2000 1250 2215 1860 2000 310

12500 2430 1250 3540 3100 4650 2000 1250 2215 1860 2000 310

13000 2430 1250 3680 3100 4800 2000 1250 2965 1860 2750 350

13500 2430 1250 3820 3100 4950 2000 1250 3040 1860 2825 350

14000 2430 1250 3960 3100 5100 2000 1250 3125 1860 2910 350

14500 2430 1250 4100 3100 5250 2000 1250 3215 1860 3000 350

15000 2430 1250 4240 3100 5400 2000 1250 3315 1860 3075 350

15500 2430 1250 4380 3100 5550 2000 1250 3130 1860 2960 350

16000 2430 1250 4520 3100 5700 2000 1250 3210 1860 3040 350

16500 2430 1250 4660 3100 5850 2000 1250 3290 1860 3120 350

17000 2430 1250 4950 3100 6100 2000 1250 3370 1860 3200 350

Select a proportioner:

---

1000

1500

2000

2500

3000

3500

4000

4500

5000

5500

6000

6500

7000

7500

8000

8500

9000

9500

10000

10500

11000

11500

12000

12500

13000

13500

14000

14500

15000

15500

16000

16500

17000

Tank with capacity, V, l

1000

А, mm

1600

В, mm

870

М, kg

1050

Н, mm

1850

С, mm

1700

D, mm

1000

Е, mm

700

F, mm

800

G, mm

860

К, mm

740

S, mm

170

Tank with capacity, V, l

1500

А, mm

1600

В, mm

870

М, kg

1180

Н, mm

1850

С, mm

2200

D, mm

1000

Е, mm

700

F, mm

1290

G, mm

860

К, mm

1230

S, mm

190

Tank with capacity, V, l

2000

А, mm

1690

В, mm

910

М, kg

1360

Н, mm

1950

С, mm

2550

D, mm

1100

Е, mm

700

F, mm

1490

G, mm

960

К, mm

1400

S, mm

200

Tank with capacity, V, l

2500

А, mm

1770

В, mm

950

М, kg

1475

Н, mm

2050

С, mm

2700

D, mm

1200

Е, mm

700

F, mm

1520

G, mm

1060

К, mm

1430

S, mm

200

Tank with capacity, V, l

3000

А, mm

1940

В, mm

1020

М, kg

1570

Н, mm

2250

С, mm

2450

D, mm

1400

Е, mm

700

F, mm

1270

G, mm

1260

К, mm

1180

S, mm

200

Tank with capacity, V, l

3500

А, mm

1940

В, mm

1020

М, kg

1685

Н, mm

2250

С, mm

2800

D, mm

1400

Е, mm

700

F, mm

1590

G, mm

1260

К, mm

1500

S, mm

200

Tank with capacity, V, l

4000

А, mm

1940

В, mm

1020

М, kg

1800

Н, mm

2250

С, mm

3100

D, mm

1400

Е, mm

700

F, mm

1590

G, mm

1260

К, mm

1500

S, mm

200

Tank with capacity, V, l

4500

А, mm

2200

В, mm

1150

М, kg

1935

Н, mm

2500

С, mm

2850

D, mm

1600

Е, mm

1250

F, mm

1490

G, mm

1460

К, mm

1350

S, mm

250

Tank with capacity, V, l

5000

А, mm

2200

В, mm

1150

М, kg

2030

Н, mm

2500

С, mm

3100

D, mm

1600

Е, mm

1250

F, mm

1640

G, mm

1460

К, mm

1500

S, mm

250

Tank with capacity, V, l

5500

А, mm

2200

В, mm

1150

М, kg

2125

Н, mm

2500

С, mm

3300

D, mm

1600

Е, mm

1250

F, mm

1640

G, mm

1460

К, mm

1500

S, mm

250

Tank with capacity, V, l

6000

А, mm

2320

В, mm

1200

М, kg

1245

Н, mm

2700

С, mm

3050

D, mm

1800

Е, mm

1250

F, mm

1565

G, mm

1660

К, mm

1400

S, mm

280

Tank with capacity, V, l

6500

А, mm

2320

В, mm

1200

М, kg

2335

Н, mm

2700

С, mm

3250

D, mm

1800

Е, mm

1250

F, mm

1665

G, mm

1660

К, mm

1500

S, mm

280

Tank with capacity, V, l

7000

А, mm

2470

В, mm

1250

М, kg

2435

Н, mm

3100

С, mm

2900

D, mm

2000

Е, mm

1250

F, mm

1330

G, mm

1860

К, mm

1140

S, мм

300

Tank with capacity, V, l

7500

А, mm

2470

В, mm

1250

М, kg

2515

Н, mm

3100

С, mm

3050

D, mm

2000

Е, mm

1250

F, mm

1490

G, mm

1860

К, mm

1300

S, mm

300

Tank with capacity, V, l

8000

А, mm

2470

В, mm

1250

М, kg

2600

Н, mm

3100

С, mm

3200

D, mm

2000

Е, mm

1250

F, mm

1550

G, mm

1860

К, mm

1360

S, mm

300

Tank with capacity, V, l

8500

А, mm

2470

В, mm

1250

М, kg

2680

Н, mm

3100

С, mm

3300

D, mm

2000

Е, mm

1250

F, mm

1720

G, mm

1860

К, mm

1530

S, mm

300

Tank with capacity, V, l

9000

А, mm

2470

В, mm

1250

М, kg

2760

Н, mm

3100

С, mm

3500

D, mm

2000

Е, mm

1250

F, mm

1920

G, mm

1860

К, mm

1730

S, mm

300

Tank with capacity, V, l

9500

А, mm

2470

В, mm

1250

М, kg

2840

Н, mm

3100

С, mm

3700

D, mm

2000

Е, mm

1250

F, mm

1890

G, mm

1860

К, mm

1700

S, mm

300

Tank with capacity, V, l

10000

А, mm

2470

В, mm

1250

М, kg

2920

Н, mm

3100

С, mm

3850

D, mm

2000

Е, mm

1250

F, mm

2215

G, mm

1860

К, mm

2000

S, mm

300

Tank with capacity, V, l

10500

А, mm

2470

В, mm

1250

М, kg

3060

Н, mm

3100

С, mm

4000

D, mm

2000

Е, mm

1250

F, mm

2215

G, mm

1860

К, mm

2000

S, mm

310

Tank with capacity, V, l

11000

А, mm

2470

В, mm

1250

М, kg

3200

Н, mm

3100

С, mm

4150

D, mm

2000

Е, mm

1250

F, mm

2215

G, mm

1860

К, mm

2000

S, mm

310

Tank with capacity, V, l

11500

А, mm

2470

В, mm

1250

М, kg

3340

Н, mm

3100

С, mm

4300

D, mm

2000

Е, mm

1250

F, mm

2215

G, mm

1860

К, mm

2000

S, mm

310

Tank with capacity, V, l

12000

А, mm

2470

В, mm

1250

М, kg

3480

Н, mm

3100

С, mm

4500

D, mm

2000

Е, mm

1250

F, mm

2215

G, mm

1860

К, mm

2000

S, mm

310

Tank with capacity, V, l

12500

А, mm

2470

В, mm

1250

М, kg

3620

Н, mm

3100

С, mm

4650

D, mm

2000

Е, mm

1250

F, mm

2215

G, mm

1860

К, mm

2000

S, mm

310

Tank with capacity, V, l

13000

А, mm

2470

В, mm

1250

М, kg

3760

Н, mm

3100

С, mm

4800

D, mm

2000

Е, mm

1250

F, mm

2965

G, mm

1860

К, mm

2750

S, mm

350

Tank with capacity, V, l

13500

А, mm

2470

В, mm

1250

М, kg

3900

Н, mm

3100

С, mm

4950

D, mm

2000

Е, mm

1250

F, mm

3040

G, mm

1860

К, mm

2825

S, mm

350

Tank with capacity, V, l

14000

А, mm

2470

В, mm

1250

М, kg

4040

Н, mm

3100

С, mm

5100

D, mm

2000

Е, mm

1250

F, mm

3125

G, mm

1860

К, mm

2910

S, mm

350

Tank with capacity, V, l

14500

А, mm

2470

В, mm

1250

М, kg

4180

Н, mm

3100

С, mm

5250

D, mm

2000

Е, mm

1250

F, mm

3215

G, mm

1860

К, mm

3000

S, mm

350

Объём ёмкости, V, л

15000

А, mm

2470

В, mm

1250

М, kg

4320

Н, mm

3100

С, mm

5400

D, mm

2000

Е, mm

1250

F, mm

3315

G, mm

1860

К, mm

3075

S, mm

350

Tank with capacity, V, l

15500

А, mm

2470

В, mm

1250

М, kg

4460

Н, mm

3100

С, mm

5550

D, mm

2000

Е, mm

1250

F, mm

3130

G, mm

1860

К, mm

2960

S, мм

350

Tank with capacity, V, l

16000

А, mm

2470

В, mm

1250

М, kg

4600

Н, mm

3100

С, mm

5700

D, mm

2000

Е, mm

1250

F, mm

3210

G, mm

1860

К, mm

3040

S, mm

350

Tank with capacity, V, l

16500

А, mm

2470

В, mm

1250

М, kg

4740

Н, mm

3100

С, mm

5850

D, mm

2000

Е, mm

1250

F, mm

3290

G, mm

1860

К, mm

3120

S, mm

350

Tank with capacity, V, l

17000

А, mm

2470

В, mm

1250

М, kg

5000

Н, mm

3100

С, mm

6100

D, mm

2000

Е, mm

1250

F, mm

3370

G, mm

1860

К, mm

3200

S, mm

350

Tank with capacity, V, l

1000

1500

2000

2500

3000

3500

4000

4500

5000

5500

6000

6500

7000

7500

8000

8500

9000

9500

10000

10500

11000

11500

12000

12500

13000

13500

14000

14500

15000

15500

16000

16500

17000

Tank with capacity, V, l l Antifire bladder tank with 10” proportioner А, mm В, mm М, kg Н, mm С, mm D, mm Е, mm F, mm G, mm К, mm S, mm

1000 1600 870 1050 1850 1700 1000 700 800 860 740 170

1500 1600 870 1180 1850 2200 1000 700 1290 860 1230 190

2000 1690 910 1360 1950 2550 1100 700 1490 960 1400 200

2500 1770 950 1475 2050 2700 1200 700 1520 1060 1430 200

3000 1940 1020 1570 2250 2450 1400 700 1270 1260 1180 200

3500 1940 1020 1685 2250 2800 1400 700 1590 1260 1500 200

4000 1940 1020 1800 2250 3100 1400 700 1590 1260 1500 200

4500 2200 1150 1935 2500 2850 1600 1250 1490 1460 1350 250

5000 2200 1150 2030 2500 3100 1600 1250 1640 1460 1500 250

5500 2200 1150 2125 2500 3300 1600 1250 1640 1460 1500 250

6000 2320 1200 2245 2700 3050 1800 1250 1565 1660 1400 280

6500 2320 1200 2335 2700 3250 1800 1250 1665 1660 1500 280

7000 2470 1250 2435 3100 2900 2000 1250 1330 1860 1140 300

7500 2470 1250 2515 3100 3050 2000 1250 1490 1860 1300 300

8000 2470 1250 2600 3100 3200 2000 1250 1550 1860 1360 300

8500 2470 1250 2680 3100 3300 2000 1250 1720 1860 1530 300

9000 2470 1250 2760 3100 3500 2000 1250 1920 1860 1730 300

9500 2470 1250 2840 3100 3700 2000 1250 1890 1860 1700 300

10000 2470 1250 2920 3100 3850 2000 1250 2215 1860 2000 300

10500 2470 1250 3060 3100 4000 2000 1250 2215 1860 2000 310

11000 2470 1250 3200 3100 4150 2000 1250 2215 1860 2000 310

11500 2470 1250 3340 3100 4300 2000 1250 2215 1860 2000 310

12000 2470 1250 3480 3100 4500 2000 1250 2215 1860 2000 310

12500 2470 1250 3620 3100 4650 2000 1250 2215 1860 2000 310

13000 2470 1250 3760 3100 4800 2000 1250 2965 1860 2750 350

13500 2470 1250 3900 3100 4950 2000 1250 3040 1860 2825 350

14000 2470 1250 4040 3100 5100 2000 1250 3125 1860 2910 350

14500 2470 1250 4180 3100 5250 2000 1250 3215 1860 3000 350

15000 2470 1250 4320 3100 5400 2000 1250 3315 1860 3075 350

15500 2470 1250 4460 3100 5550 2000 1250 3130 1860 2960 350

16000 2470 1250 4600 3100 5700 2000 1250 3210 1860 3040 350

16500 2470 1250 4740 3100 5850 2000 1250 3290 1860 3120 350

17000 2470 1250 5000 3100 6100 2000 1250 3370 1860 3200 350

Specifications for a diaphragm proportioner (DS)

Select a proportioner:

---

DS-65

DS-80

DS-100

DS-150

DS-200

DS-250

Условный диаметр, мм (дюйм)

65 (2½")

Расход раствора пенообразователя, min-max, л/мин

75-650

Концентрация дозируемого пенообразователя

1 %, 3 %, 6 %

Условный диаметр, мм (дюйм)

80 (3")

Расход раствора пенообразователя, min-max, л/мин

100–900

Концентрация дозируемого пенообразователя

1 %, 3 %, 6 %

Условный диаметр, мм (дюйм)

100 (4")

Расход раствора пенообразователя, min-max, л/мин

250–1800

Концентрация дозируемого пенообразователя

1 %, 3 %, 6 %

Условный диаметр, мм (дюйм)

150 (6")

Расход раствора пенообразователя, min-max, л/мин

450-3500

Концентрация дозируемого пенообразователя

1 %, 3 %, 6 %

Условный диаметр, мм (дюйм)

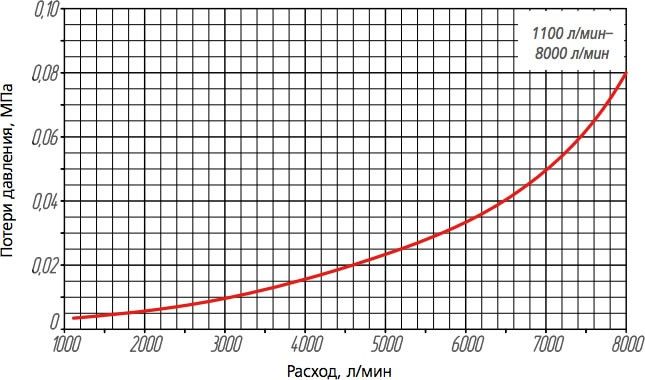

200 (8")

Расход раствора пенообразователя, min-max, л/мин

1100-8000

Концентрация дозируемого пенообразователя

1 %, 3 %, 6 %

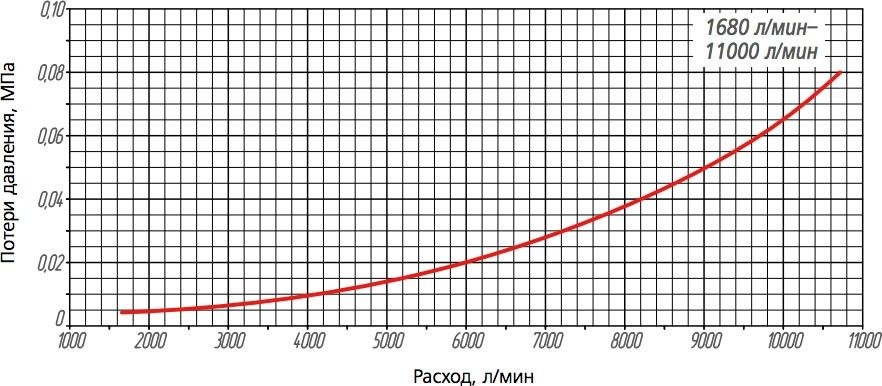

Условный диаметр, мм (дюйм)

250 (10")

Расход раствора пенообразователя, min-max, л/мин

1680-11000

Концентрация дозируемого пенообразователя

1 %, 3 %, 6 %

Indicator name Indicator value DS-65 DS-80 DS-100 DS-150 DS-200 DS-250

Nominal diameter mm (inch) 65 (2½") 80 (3") 100 (4") 150 (6") 200 (8") 250 (10") Foam concentrate solution 75–650 100–900 250–1800 450–3500 1100–8000 1680–11000 Foam concentrate 1 %, 3 %, 6 %

Optionally, proportioners can be manufactured with the insertion range of 0.5% and with other flow rates.

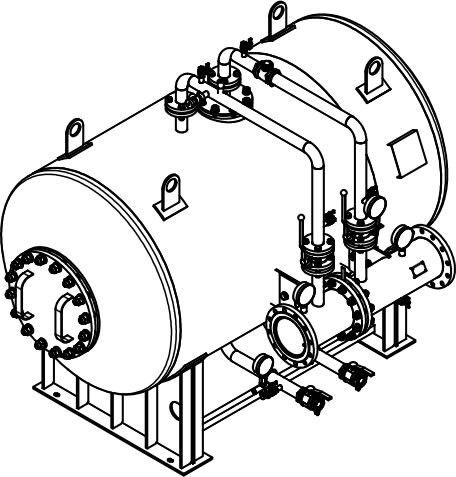

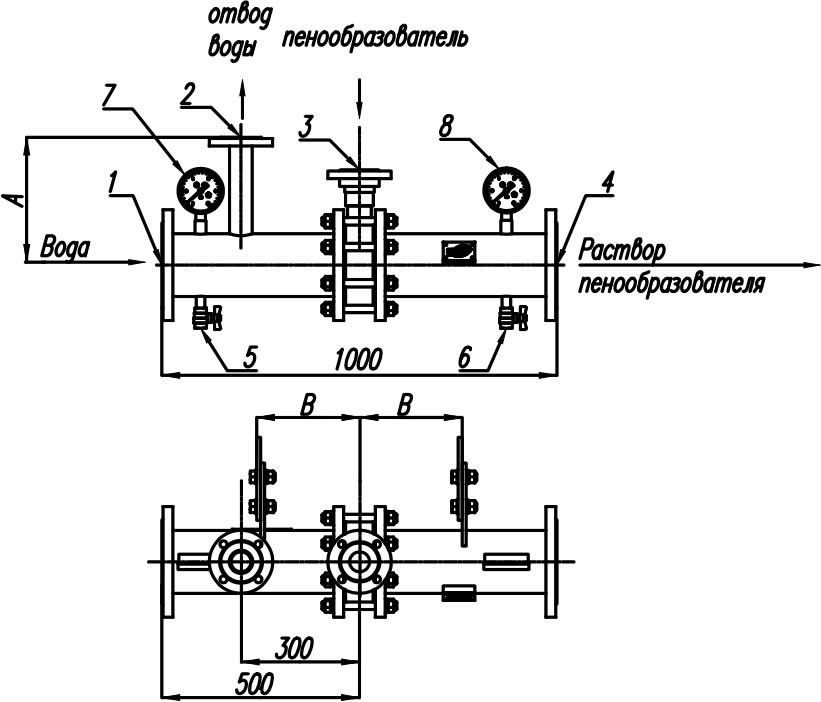

The main elements and overall dimensions of DS proportioners

The main elements of the diaphragm proportioner (DS):

Выберите дозирующее устройство:

---

ДС-65

ДС-80

ДС-100

ДС-150

ДС-200

ДС-250

Размер, мм (дюйм)

65 (2½")

Тип фланцев по ГОСТ 33259-2015 (поз. 1 и 6 на чертеже)

65-16-01-1

Тип фланцев по ГОСТ 33259-2015 (поз. 2 и 4 на чертеже)

50-16-01-1

A, мм

220

B, мм

200

Масса, кг

30

Размер, мм (дюйм)

80 (3")

Тип фланцев по ГОСТ 33259-2015 (поз. 1 и 6 на чертеже)

80-16-01-1

Тип фланцев по ГОСТ 33259-2015 (поз. 2 и 4 на чертеже)

50-16-01-1

A, мм

285

B, мм

215

Масса, кг

40

Размер, мм (дюйм)

100 (4")

Тип фланцев по ГОСТ 33259-2015 (поз. 1 и 6 на чертеже)

100-16-01-1

Тип фланцев по ГОСТ 33259-2015 (поз. 2 и 4 на чертеже)

50-16-01-1

A, мм

295

B, мм

220

Масса, кг

50

Размер, мм (дюйм)

150 (6")

Тип фланцев по ГОСТ 33259-2015 (поз. 1 и 6 на чертеже)

150-16-01-1

Тип фланцев по ГОСТ 33259-2015 (поз. 2 и 4 на чертеже)

50-16-01-1

A, мм

320

B, мм

235

Масса, кг

75

Размер, мм (дюйм)

200 (8")

Тип фланцев по ГОСТ 33259-2015 (поз. 1 и 6 на чертеже)

200-16-01-1

Тип фланцев по ГОСТ 33259-2015 (поз. 2 и 4 на чертеже)

50-16-01-1

A, мм

350

B, мм

240

Масса, кг

100

Размер, мм (дюйм)

250 (10")

Тип фланцев по ГОСТ 33259-2015 (поз. 1 и 6 на чертеже)

250-16-01-1

Тип фланцев по ГОСТ 33259-2015 (поз. 2 и 4 на чертеже)

80-16-01-1

A, мм

380

B, мм

240

Масса, кг

120

Indicator name Indicator value DS-65 DS-80 DS-100 DS-150 DS-200 DS-250

Size, mm (inch) 65 (2½") 80 (3") 100 (4") 150 (6") 200 (8") 250 (10")

Type of flanges in accordance with GOST 33259-2015 65-16-01-1 80-16-01-1 100-16-01-1 150-16-01-1 200-16-01-1 250-16-01-1

Type of flanges in accordance with GOST 33259-2015 50-16-01-1 50-16-01-1 50-16-01-1 50-16-01-1 50-16-01-1 80-16-01-1

A, mm 220 285 295 320 350 380

B, m 200 215 220 235 240 240

Weight, kg 30 40 50 75 100 120

Hydraulic Loss Graphs for DS Proportioners

To compare two graphs, select both values.

Select DS proportioner

---

DS-65

DS-80

DS-100

DS-150

DS-200

DS-250

Select DS proportioner

---

DS-65

DS-80

DS-100

DS-150

DS-200

DS-250

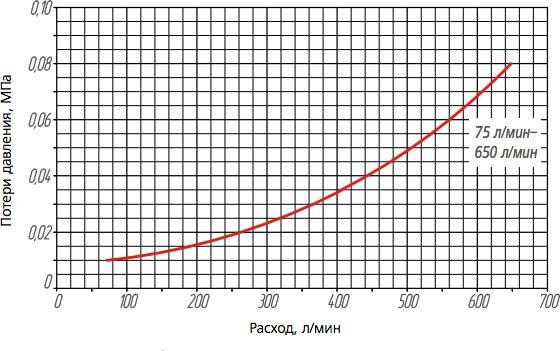

Hydraulic loss graphs for DS-65

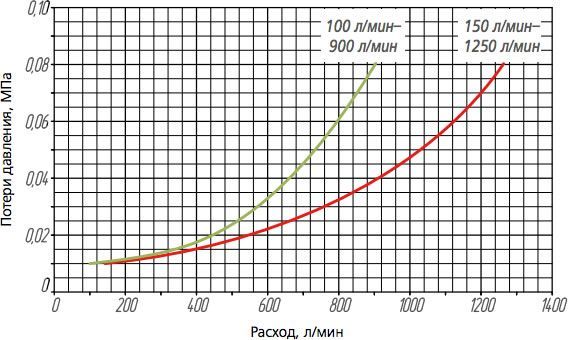

Hydraulic loss graphs for DS-80

Hydraulic loss graphs for DS-100

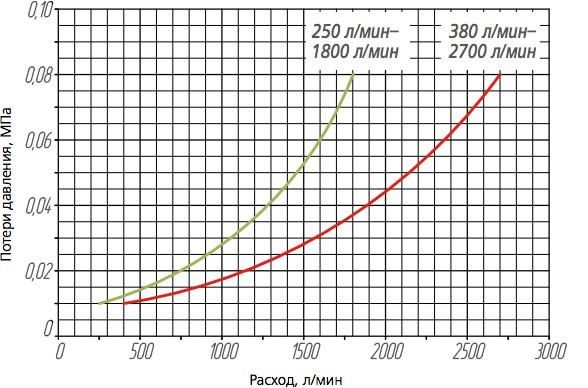

Hydraulic loss graphs for DS-150

Hydraulic loss graphs for DS-200

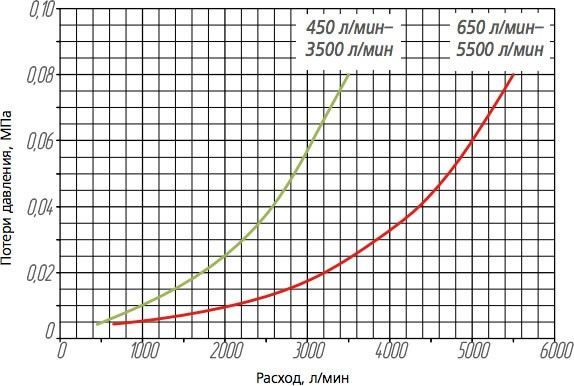

Hydraulic loss graphs for DS-250

Specifications for a wide range proportioner (DShD)

Выберите дозирующее устройство:

---

ДШД-100

ДШД-150

ДШД-200

ДШД-250

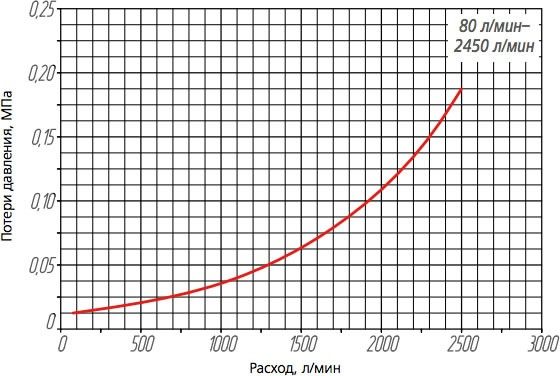

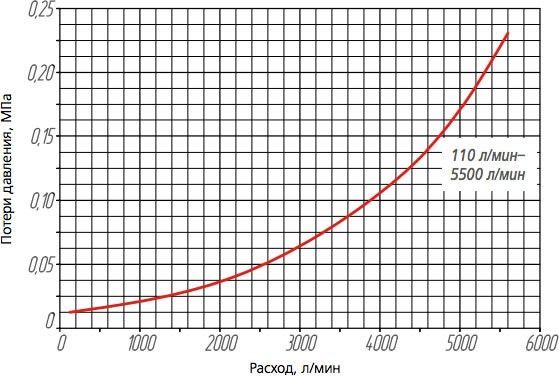

Условный диаметр, мм (дюйм)

100 (4")

Расход раствора пенообразователя, min-max, л/мин

80–2450

Концентрация дозируемого пенообразователя

1 %, 3 %, 6 %

Условный диаметр, мм (дюйм)

150 (6")

Расход раствора пенообразователя, min-max, л/мин

110–5500

Концентрация дозируемого пенообразователя

1 %, 3 %, 6 %

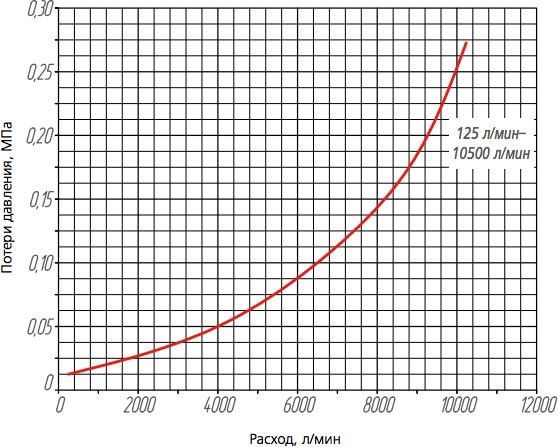

Условный диаметр, мм (дюйм)

200 (8")

Расход раствора пенообразователя, min-max, л/мин

125–10500

Концентрация дозируемого пенообразователя

1 %, 3 %, 6 %

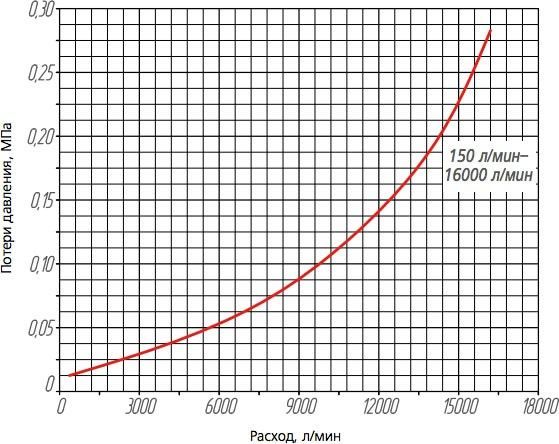

Условный диаметр, мм (дюйм)

250 (10")

Расход раствора пенообразователя, min-max, л/мин

150–16000

Концентрация дозируемого пенообразователя

1 %, 3 %, 6 %

Indicator name Indicator value DShD-100 DShD-150 DShD-200 DShD-250

Nominal diameter, mm (inch) 100 (4") 150 (6") 200 (8") 250 (10") Foam concentrate solution flow rate, 80–2450 110–5500 125–10500 150–16000 Foam concentrate 1 %, 3 %, 6 %

Optionally, proportioners can be manufactured with the insertion rate of 0.5% and with other flow rates.

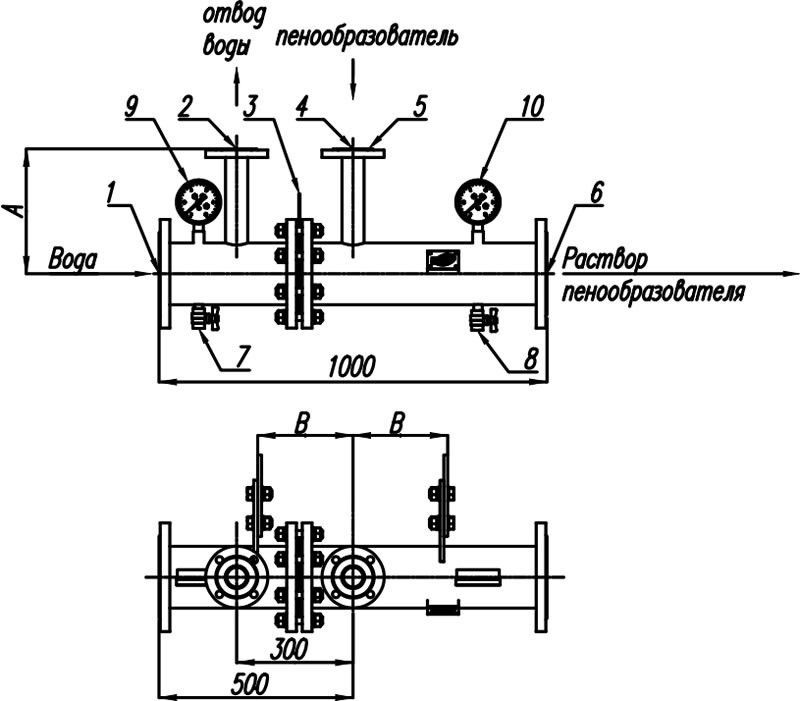

The main elements and overall dimensions of DShD proportioners

1 – flange to feed water from the main line to the proportioner;

Выберите дозирующее устройство:

---

ДШД-100

ДШД-150

ДШД-200

ДШД-250

Размер, мм (дюйм)

100 (4")

Тип фланца по ГОСТ 33259-2015

100-16-01-1

Тип фланца по ГОСТ 33259-2015

50-16-01-1

A, мм

295

B, мм

200

Масса, кг

65

Размер, мм (дюйм)

150 (6")

Тип фланца по ГОСТ 33259-2015

150-16-01-1

Тип фланца по ГОСТ 33259-2015

50-16-01-1

A, мм

320

B, мм

200

Масса, кг

95

Размер, мм (дюйм)

200 (8")

Тип фланца по ГОСТ 33259-2015

200-16-01-1

Тип фланца по ГОСТ 33259-2015

80-16-01-1

A, мм

350

B, мм

210

Масса, кг

140

Размер, мм (дюйм)

250 (10")

Тип фланца по ГОСТ 33259-2015

250-16-01-1

Тип фланца по ГОСТ 33259-2015

80-16-01-1

A, мм

380

B, мм

230

Масса, кг

170

Indicator name Indicator value DShD-100 DShD-150 DShD-200 DShD-250

Size, mm (inch) 100 (4") 150 (6") 200 (8") 250 (10") Type of flanges in accordance with GOST 33259-2015 100-16-01-1 150-16-01-1 200-16-01-1 250-16-01-1 Type of flanges in accordance with GOST 33259-2015 50-16-01-1 50-16-01-1 80-16-01-1 80-16-01-1 A, мм 295 320 350 380 B, мм 200 200 210 230 Масса, кг 65 95 140 170

Hydraulic Loss Graphs for DShD Proportioners

To compare two graphs, select both values.

Select DShD proportioner

---

DShD-100

DShD-150

DShD-200

DShD-250

Select DShD proportioner

---

DShD-100

DShD-150

DShD-200

DShD-250

Hydraulic loss graphs for DShD-100

Hydraulic loss graphs for DShD-150

Hydraulic loss graphs for DShD-200

Hydraulic loss graphs for DShD-250

Component parts list for Antifire bladder tank base case

1 – shut-off valve on water feed pipeline to the tank;

Optionally, the product can be supplied with additional equipment.

Для просмотра полного описания технических характеристик отправьте заявку или войдите под своим профилем