FIREFIGHTING AT OIL PROCESSING PLANTS

The Pozhneftehim has been designing foam fire extinguishing systems for hazardous facilities in the oil, gas and petrochemical industries since 2004. For processing installations, STU for fire safety and the “Fire safety measures” (MOPB) section of design documentation can be developed.

The Pozhneftehim is ready to supply a set of firefighting equipment and foam concentrates for a fire extinguishing system and water cooling, to carry out installation supervision and take part in commissioning and acceptance tests.

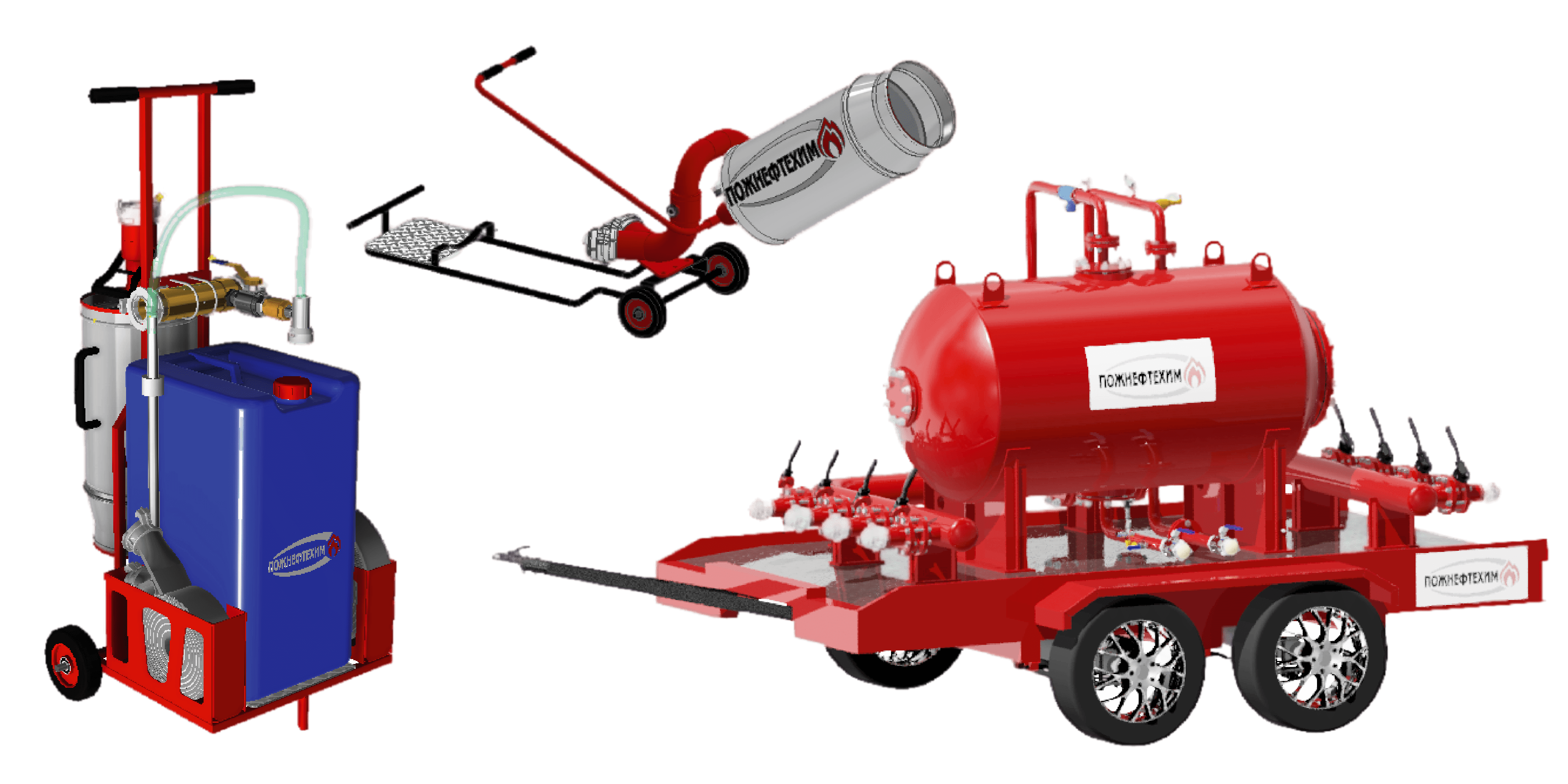

Choose your fire extinguishing system

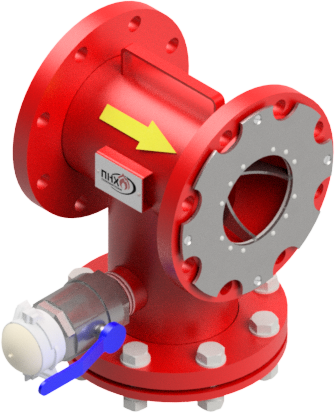

Antifire Universal water-foam nozzle UVPN*

Antifire Universal water-foam nozzle UVPN*

Turbopen Universal fire filter

Turbopen Universal fire filter

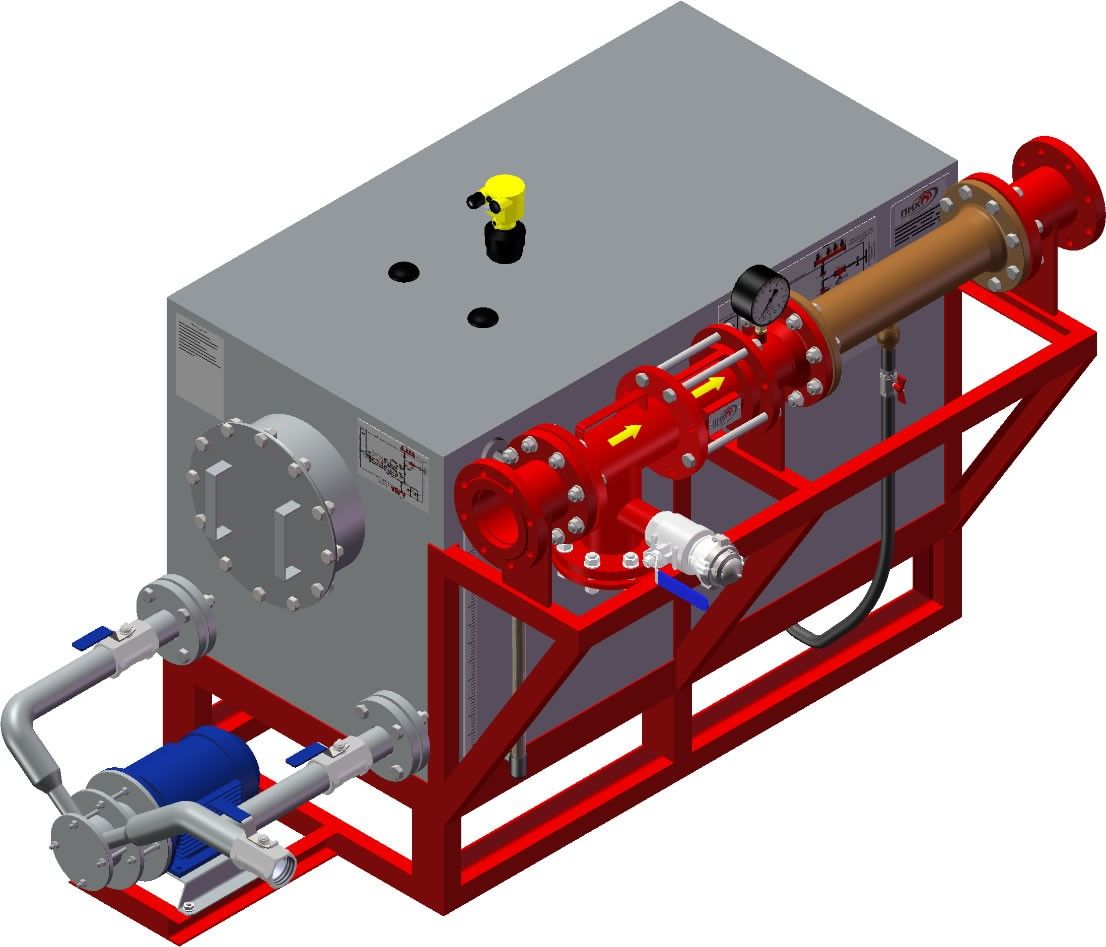

Foam concentrate storage and proportioning system SKhDP

Foam concentrate storage and proportioning system SKhDP

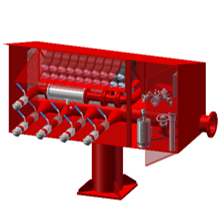

Tower universal fire filter PFU

Tower universal fire filter PFU

*devices on a stationary flange (PU-A, PU-B) or on an oscillator

Oil processing installations: fire safety requirements

According to SP 4.13130.2013, "a processing installation means an industrial complex of buildings, structures and outdoor installations located on a separate site of the enterprise and intended for the implementation of the oil refining process". The section focuses on outdoor units, which are equipped with water cooling systems in accordance with current standards, as well as buildings, premises and reservoirs with flammable and combustible liquids (as part of process installations), which are protected by foam fire extinguishing systems.

Water cooling of processing plants

According to GOST R 12.3.047-2012 Fire safety of processes, "to prevent the increase in the scale of an accident during a fire, the processing equipment of production facilities must be protected from heat radiation by water irrigation installations (fire monitors, stationary water irrigation installations)."

Regulatory documents contain requirements for a water irrigation system for columns and processing equipment:

VUPP-88; clause 8.9. Fire monitors shall be installed:

a) in outdoor explosive and fire hazardous installations to protect equipment containing flammable gases, flammable and combustible liquids

8.26. Protection of column equipment to a height of up to 30 m should be carried out by monitors and mobile firefighting equipment. With a column equipment of more than 30 m high, their protection should be carried out in combination, namely: up to a height of 30 m with fire monitors and mobile firefighting equipment, and above 30 m - with stationary irrigation systems.

GOST R 12.3.047-2012; Appendix M

M.2 Fire monitors shall be installed:

- in outdoor installations of categories AN, BN and VN - for the protection of column equipment with a height of up to 30 m containing combustible gases (GG), flammable (HIL) and combustible liquids (FL), and in oil refining, petrochemical, chemical and gas processing enterprises - for protection of apparatus and equipment containing GGH, HIL and FL

M.8 At a column apparatus height of more than 30 m, their protection at a height of more than 30 m should be carried out by stationary irrigation installations.

Fire monitors for water cooling of column units of processing installations

For the column apparatus, fire monitors are provided to cool the equipment with water. It is important to increase their functionality and provide the ability to supply foam to extinguish local spills from a safe distance. For this end, we recommend implementing the universal fire monitors (LS-SU) manufactured by Pozhneftehim.

The nozzles should be connected to a fire water supply and a pipeline with a foam concentrate solution.

Fire nozzles for water curtains

For water curtains nozzles NP II and fan-type fire nozzles NP III are used.

NP-III nozzles are used to create water curtains set on the paths of probable clouds of dangerous vapors and gases. Given the technical characteristics, the nozzle can also be used to protect against heat fluxes.

Fire nozzles (NP-II type) create a water curtain against heat flows by supplying water mist to the gap zones formed between the nozzles.

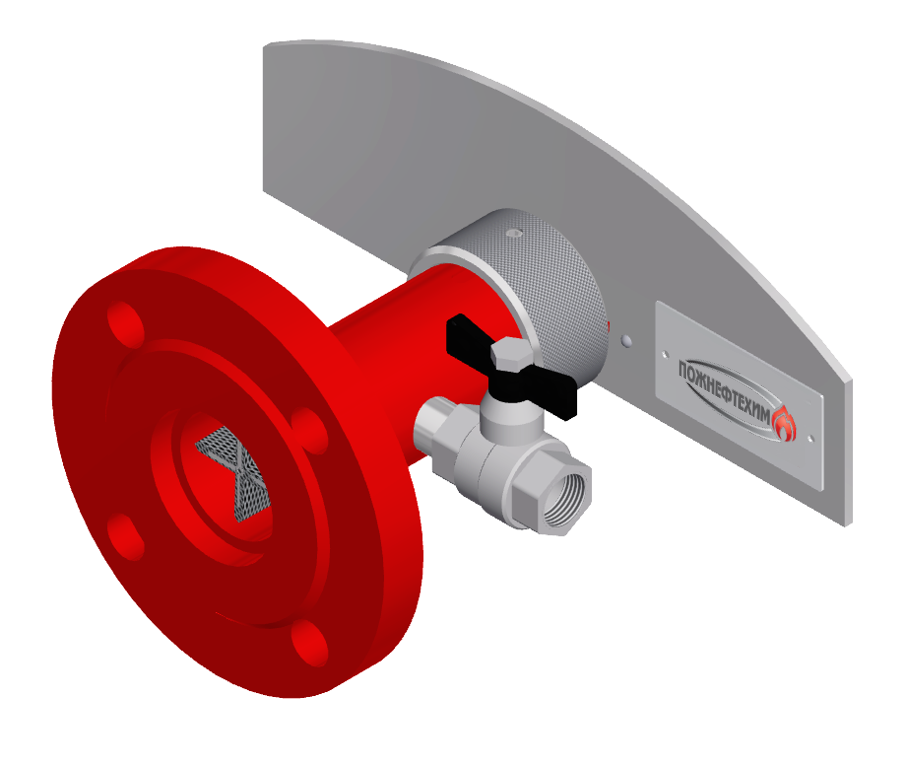

To protect the slotted openings of the nozzles and the gaps of the foam generators, it is important to implement the Tauer Universal fire filters (PFU).

Equipment for fire water pipelines in processing installations

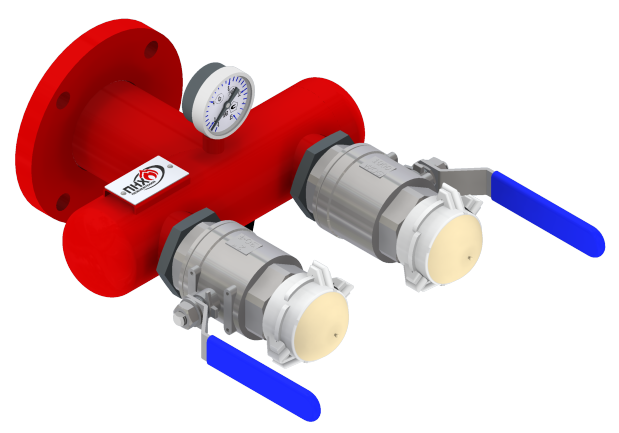

Surface fire water pipelines should be equipped with Rubezh Fire hose cabinets (BPG).

Rubezh BPG manufactured by Pozhneftehim provides water intake through special nipples with fire connection heads of the GM type in accordance with GOST R 53279-2009.

Water is supplied to the fire site using fire hoses and fire nozzles. An important feature of the Rubezh BPG is a vessel for storing a foam concentrate and an ejector-type proportioner, which can additionally provide foam to extinguish combustible liquids.

Water/foam nozzles for firefighting and water cooling on the shelf racks of processing installations

It is advisable to protect the shelves with oil processing equipment with the universal Antifire water-foam nozzles on a rotary device with an oscillator, which is capable of applying water for water cooling or a foam concentrate solution (low expansion foam) for firefighting. A foam fire extinguishing system may be provided on the basis of clauses 5.2-5.6 and 5.8 of GOST R 12.3.047-2012.

Sections with the Antifire UVPN should be brought out with dry pipes to the passage for firefighting equipment or permanently connected to a pipeline with a foam concentrate solution.

Fire extinguishing and fire hazard at processing installations

Processing installations are intended for the processing of oil, oil products and liquefied petroleum gases. These industrial facilities pose a great fire hazard due to a combination of the following factors:

- high congestion of equipment units at a site;

- presence of large volumes of explosive gases and liquids under high pressure and at high temperature;

- high temperature of processing devices and pipelines.

The fire brigades arriving at the fire are required by instructions to conduct reconnaissance, evacuate people, provide cooling of facilities adjacent to the burning ones, and only thereafter proceed to extinguish the fire. Technical means for extinguishing a fire in accordance with clause 8.15 of VUPP-88 are dry pipe risers to reduce the time for applying water and foam.

In the event of depressurization of technological equipment or pipelines with an oil product, spilling and ignition of combustible substances occur. The consequences of such fires are dramatic, including loss of life and economic damages.

At the facilities that make up the process plants, major fires occur.

According to clause 5.2 of GOST R 12.3.047-2012, the analysis of the fire hazard of processes includes:

- monitoring possibility of combustible environment formation inside rooms, equipment and pipelines;

- rating of premises, buildings and outdoor installations for explosion and fire hazard;

- determination of the make-up of fire, explosion and fire protection systems for processes;

- development of measures to improve fire safety of processes and their individual sections, etc

It is extremely important to choose the foam fire extinguishing system for hazardous facilities as a part of the processing site. The system must take into account the fire hazard of each particular object

Foam fire extinguishing systems for processing installations use foam generators, storage systems and a proportioner of foam concentrate, as well as auxiliary target equipment (manifolds for connecting fire equipment, Foamix pressure proportioners, fire filters, etc.).

Fire cabinet on fire water supply system for oil processing unit

For the quick elimination by personnel of small fire beds, it is advisable to provide foam fire cabinets on the water supply system (on shelves, column platforms, near process tanks and equipment).

MasterPen ShPP contains a vessel for storing a foam concentrate, a proportioner and a foam cannon. Foam fire cabinet manufactured by Pozhneftehim is approved for installation in rooms of all categories of fire hazard.

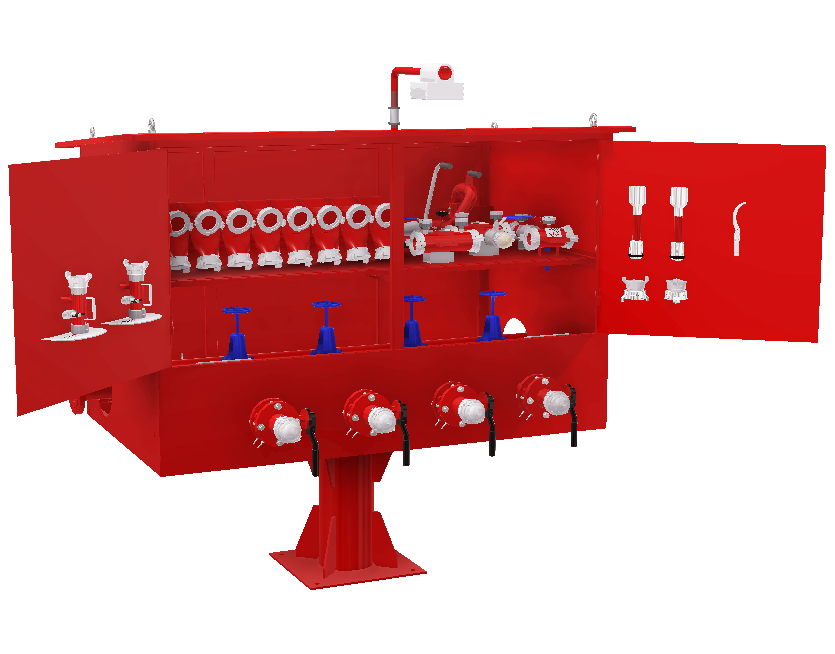

The block-container on the fire water supply system of the process installation

Vityaz block-containers for firefighting shall be installed on a fire water pipeline. The use of BK-PT will increase the level of fire protection at minimal cost.

Vityaz BK-PT is manufactured of I, II, III or IV degree of fire resistance according to the requirements of regulatory documentation with the attachment of the test conclusions of fire laboratory or certificates of conformity.

Block-containers manufactured by Pozhneftehim are needed if a pipeline with a foam concentrate solution is not available near the process unit (for example, the unit is under reconstruction).

Foam generator for extinguishing a fire with medium expansion foam

Hazardous production facilities as a part of processing plants can be protected by fire extinguishing systems with low and medium expansion foam. Low expansion foam is applied by the Antifire water/foam nozzle, which is also designed to apply water for water cooling (see above).

Medium expansion foam is applied by the Turbopen universal foam generator on a rotating table with an oscillator. Turbopen UGP applies a fire extinguishing jet in a wide pressure range with high penetrating power and a stream range.

Design of fire extinguishing systems for processing installations

When reconstructing hazardous production and industrial facilities, it is not easy to maintain the separation distances that are provided for by current regulatory documents. To ensure a sufficient level of fire safety, additional compensatory measures are being developed. Forced deviations from the requirements of regulatory documents are justified in the Special technical conditions for fire safety.

When designing technological installations, foreign (usually European) norms and standards can be taken into account. In such projects, some of the requirements of national standards are not initially complied with; therefore, compensatory measures should be chosen in the fire safety management system.

In addition to STU, the Pozhneftehim specialists can additionally prepare the following documents at the design stage:

- Fire protection concept for a processing plant;

- Раздел «Section "Fire safety measures" for the processing installation.

Fire protection issues should be addressed comprehensively. If the design documentation contains incorrect concepts of fire protection systems, their audit is carried out. This is an assessment of the compliance of design solutions with the requirements of regulatory documents (GOST, SP, etc.) in the field of fire safety with the subsequent development and approval of new STU and MOSB.

Regulatory basis for the use of foam fire extinguishing systems at facilities as a part of technological installations

A fire in technological installations entails considerable economic losses for the enterprise owner. Since water extinguishing is not permissible for HIL and FL, fire extinguishing systems at individual sites are designed to contain the fire and prevent its spread. Water cooling systems are designed to cool objects that are next to that on fire.

According to clause 5.17-18 GOST R 12.3.047-2012, fire protection of processes must be ensured by "the use of fire extinguishing and water irrigation systems (automatic, if necessary) and appropriate types of firefighting equipment", as well as "devices that limit the spread of fire." It is possible to limit the spread of fire with the help of fire barriers, emergency shutdown of processing installations and communications, the use of means that limit the spill of HIL and FL.

The difficulty of extinguishing fires in processing installations is that stationary fire extinguishing installations can be disabled as a result of explosions or under prolonged exposure to high temperatures. Therefore, in addition to local stationary fire extinguishing installations, the possibility of firefighting by mobile fire equipment is provided.

Foam concentrates for extinguishing objects as part of processing installations

According to clause 5.19 of GOST R 12.3.047-2012, “the choice of extinguishing agents, compositions <...> should be carried out at the stage of designing processes, depending on the physicochemical properties of the processed substances and extinguishing agents and design of fire scenarios”.

Different foam concentrates can be used at different facilities of the same process unit. For extinguishing polar liquids, AFFF/AR and S/AR are used; for non-polar liquids, AFFF is used. Fluorosynthetic film-forming foam concentrates are more effective for fire extinguishing flammable and combustible liquids than the synthetic ones. Before choosing a fire extinguishing agent and equipment to be combined with it, consult the Pozhneftehim specialists.

The Pozhneftehim firefighting equipment and foam concentrates

The Pozhneftehim produces AQUAFOM firefighting equipment and foam concentrates for fire extinguishing systems of technological installations, as well as various buildings and premises of oil and gas and petrochemical enterprises:

- AQUAFOM foam concentrates of AFFF, AFFF/AR, S/AR, S types;

- foam generators of low, medium and high expansion;

- fire monitors;

- auxiliary firefighting equipment;

- foam concentrate storage and proportioning systems;

- block-containers for fire suppression are modular buildings with proportioning systems and pumping stations.

Domestic legislation lacks national standards for many types of foam generators. When choosing a supplier of equipment, a guarantee of the quality and performance of fire equipment is considered to be the availability at the Equipment Manufacturer of an accredited stand for equipment hydraulic testing, as well as the provision of documents:

- license of the Ministry of Emergencies of the Russian Federation for installation, maintenance and repair of fire safety facilities for buildings and structures (for modular buildings);

- SRO certificate of admission to the preparation of draft measures to ensure fire safety of capital construction facilities, including especially hazardous and technically-intensive facilities (for modular buildings);

- certificate of the Ministry of Emergency Situations of the Russian Federation on accreditation for carrying out calculations for assessing fire risk and preparing a conclusion on the fulfillment (non-fulfillment) of the conditions for compliance of the protected object with fire safety requirements;

- certificate of quality system GOST ISO 9001;

- inclusion of a fire equipment manufacturer in the register of the National Welding Control Agency (NAKS);

- certificate of conformity issued by an accredited body of EMERCOM of Russia;

- manufacturer written confirmation for the Customer representative production inspection to take part in acceptance tests;

- certificate (declaration) for compliance with TR TS 032/2013 for the bladder tank;

- safety justification (OB) specified in paragraph 45 of the TR TS 032/2013 for the bladder tank;

- certificate of compliance with the requirements of GOST 30546.1-98, GOST 30546.2-98, GOST 30546.2-98 (earthquake resistance 9 points on the MSK-64 scale) for a bladder tank (if necessary);

- justifying calculation of the corrosion rate of the bladder tank inner surface, performed by an accredited organization (for bladder tanks).

Проектирование систем пожаротушения для технологической установки включает следующие услуги

Contact information to order Pozhneftehim complex supplies

Questions concerning the choice of foam concentrates for fire extinguishing

Tatyana Potapenko, foam project manager +7 (499) 703 01 32, ext.172

Questions concerning the choice of firefighting equipment

Sergey Vypritsky, Project Manager +7 (499) 703 01 32, ext.153

Questions on documentation regarding Fire safety measures (MOPB) and Special technical conditions (STU)

Sergey Titenkov, Head of Regulatory and Technical Department +7 (499) 703 01 32, ext.159

AQUAFOM foam concentrate

AQUAFOM foam concentrate  Fire cabinet MasterPen

Fire cabinet MasterPen  Antifire fire monitor

Antifire fire monitor  Fire tower PVU

Fire tower PVU  Rubezh fire cabinet BPG

Rubezh fire cabinet BPG  Fire hydrant manifolds UPT

Fire hydrant manifolds UPT  Antifire bladder tank BD

Antifire bladder tank BD  Fire stabilizer PUS

Fire stabilizer PUS  Vityaz block-container for fire suppression BK-PT

Vityaz block-container for fire suppression BK-PT  ОРК

ОРК Fan fire nozzles NP-III

Fan fire nozzles NP-III